Types of side channel blowers

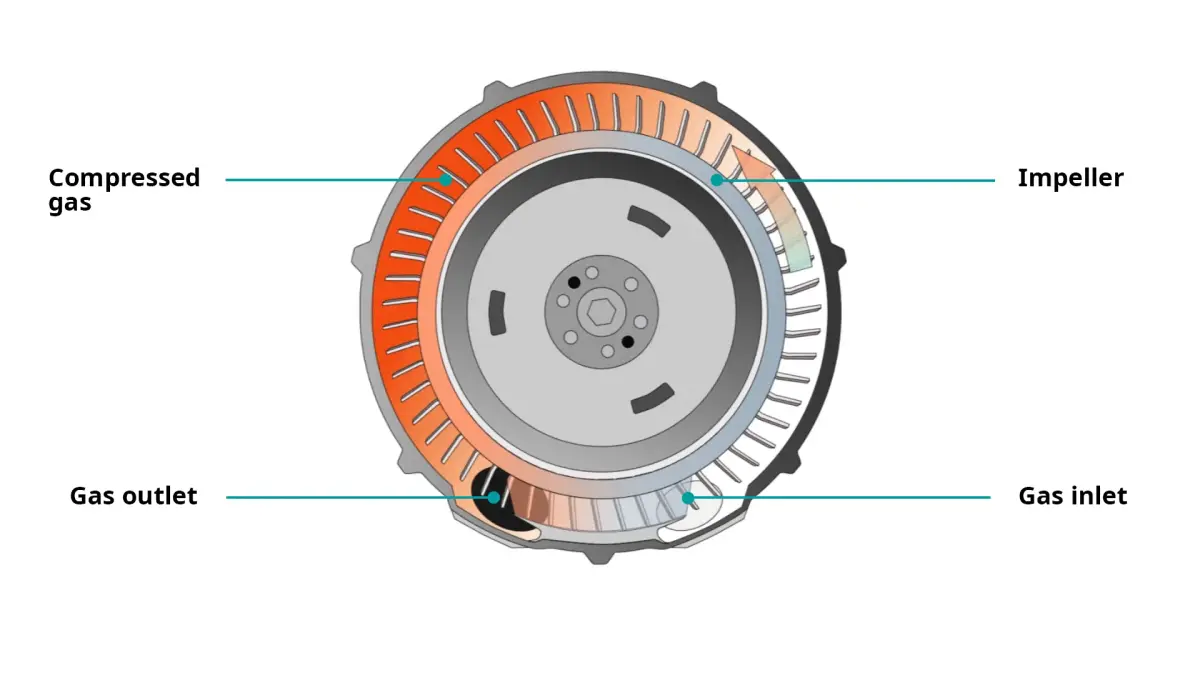

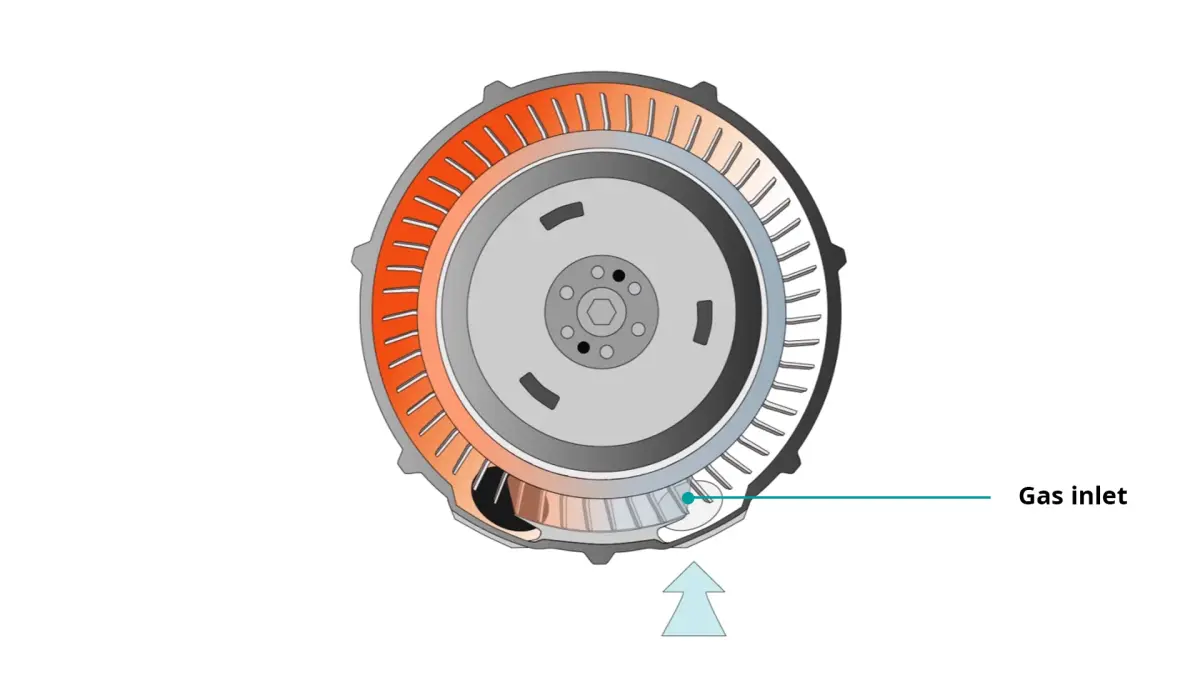

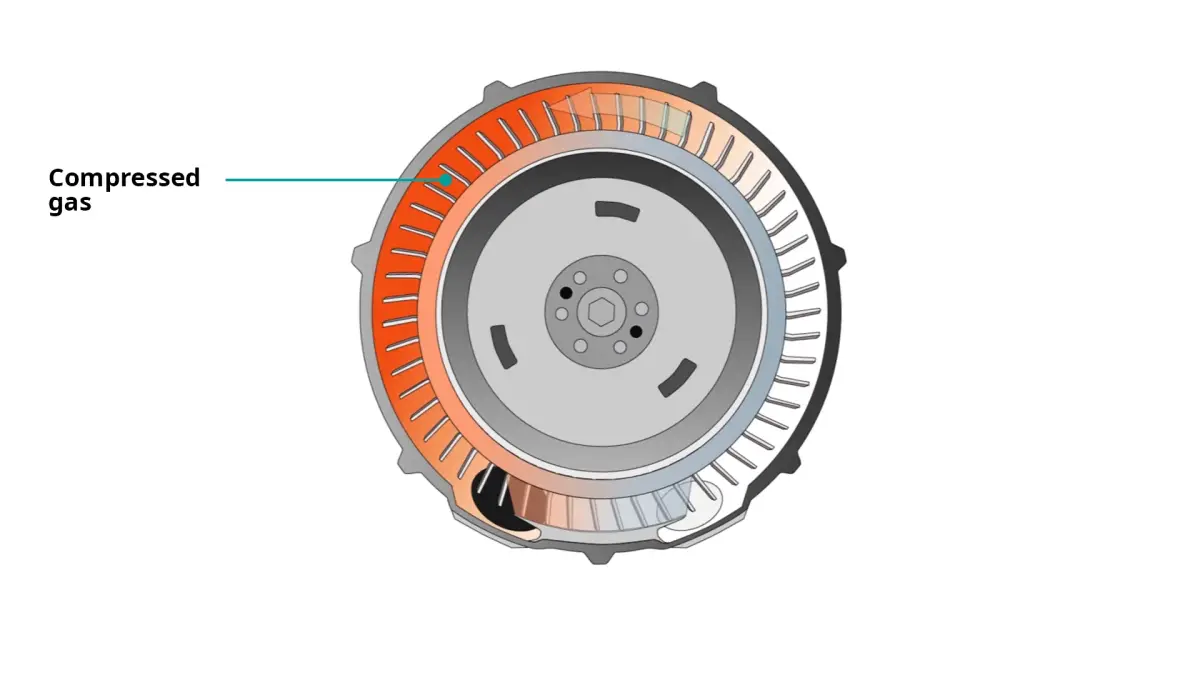

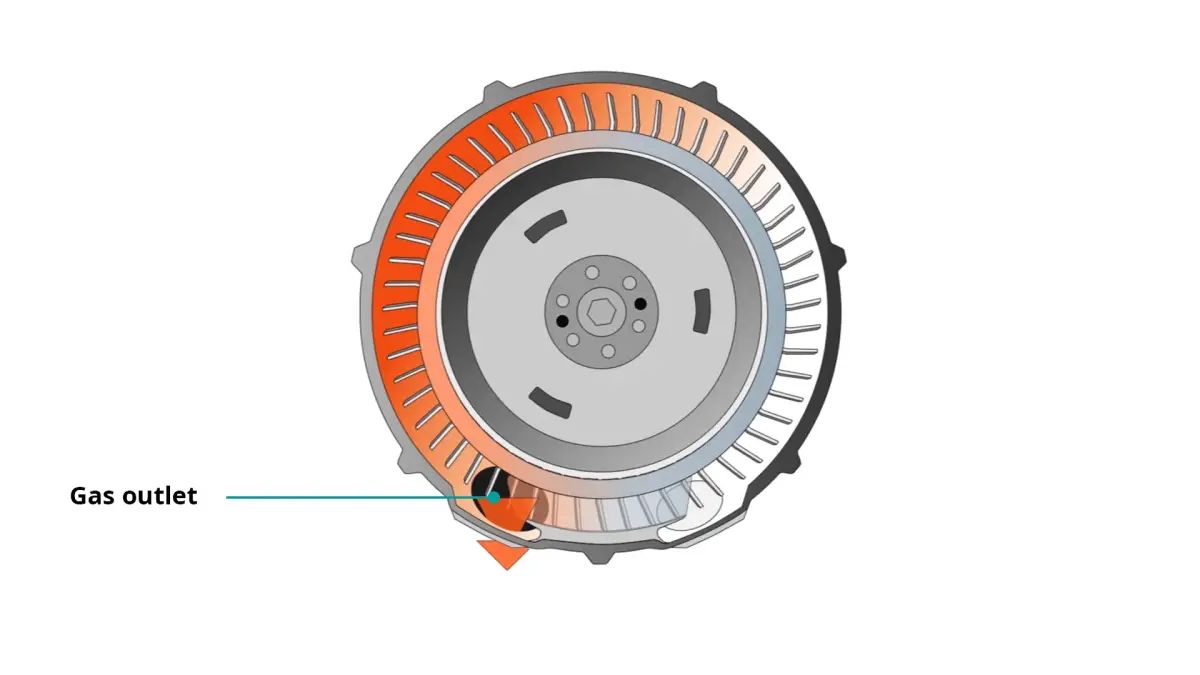

SAMOS side channel blowers are available in single- and two-stage versions. In single-stage side channel blowers, the pumped medium is discharged after one rotation, while two-stage versions convey it to the second stage after one rotation. This leads to higher differential pressures.The die-cast aluminum or cast-iron construction makes SAMOS very robust. The impeller is made of aluminum alloy and is dynamically balanced. Thus, our side channel blowers generate very low vibration and noise levels. The large variety of sizes provides the opportunity to choose the perfect SAMOS for any application, both technically and economically.

Product series | Nominal pumping speed | Version |

|---|---|---|

SAMOS SB | 50-1,600 m3/h | single- and two-stage |

SAMOS SI | 40-2,200 m3/h | single- and two-stage |