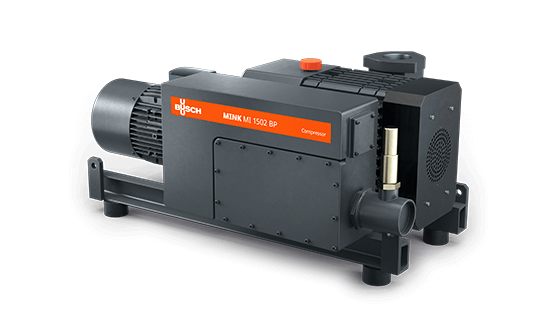

Efficient and Constant Overpressure Supply for Numerous Industrial Applications

Flexible

Designed for numerous industrial applications of up to 2.0 bar(g), inlet filter and pressure relief valve as standard

Reliable

Air cooling, constantly high volume flow throughout the entire life cycle

Nearly maintenance-free

Dry and contact-free compression

Technical specifications

Markets & applications

Biogas handling

-

Upgrading - physical scrubber

-

Upgrading - membrane

-

Upgrading - water scrubber

-

Circulation

Fish farming

-

Vacuum for transportation

-

Vacuum packaging

-

Extraction of slaughter waste

-

Pneumatic suction conveying of ice for cooling

-

Thermoforming

-

Retaining vacuum for filleting

-

MAP packaging

-

Pneumatic transportation of live fish

Food processing

-

Powder processing

-

Pneumatic conveying of foodstuffs

Packaging

-

Blow molding

-

Blister packaging

Wastewater treatment

-

Water priming

-

Vacuum sewerage

-

Vacuum disposal

-

Ground water removal

-

Vacuum toilets

Design options

-

Aqua - for higher water vapor capacity.