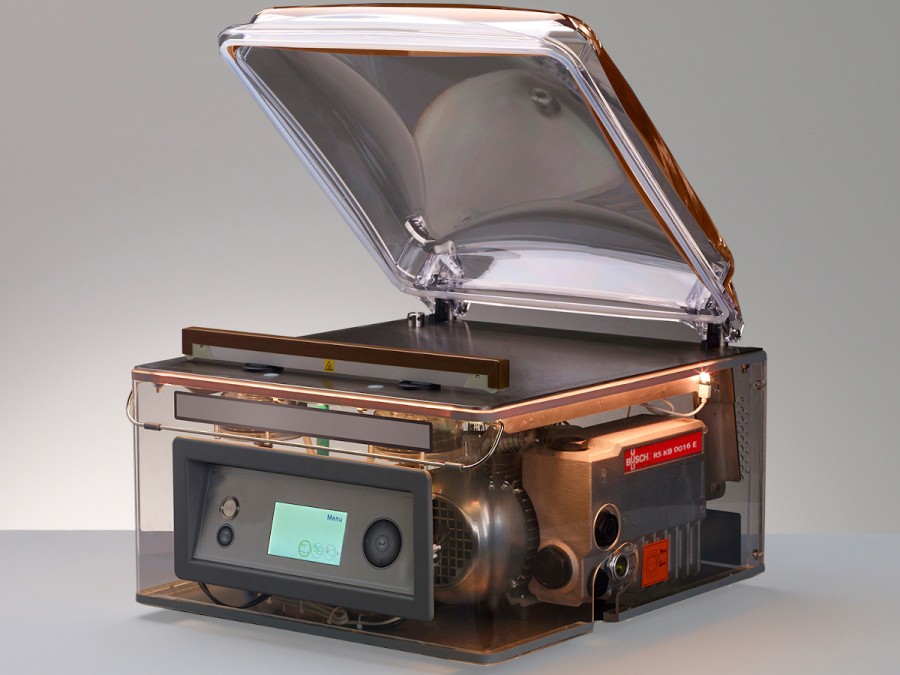

Fig. 1: Typical R5 rotary vane vacuum pump from Busch for use in chamber packaging machines. Source: Busch Vacuum Solutions.

Vacuuming of Fresh Food

Tips for correctly handling the vacuum pump in a chamber machine

Vacuuming fresh food using chamber machines is often a daily activity in butcher shops, at fresh food counters for meat, sausage, and cheese products, as well as in the food service industry.

All fresh foods contain more or less unbound water, which partially evaporates during vacuum packaging. This can have an influence on the quality of the product. Furthermore, if the packaging machine is not permanently in operation, the packaging result may deteriorate, or the packaging process may take too long. If the packaging process takes too long, the food to be packaged will lose weight. Below is an explanation of the physical operations performed during the packaging process, as well as some practical advice to ensure trouble-free operation and a long service life for the vacuum pump in the packaging machine.

R5 oil-lubricated rotary vane vacuum pumps have been specially developed for packaging food and have achieved the highest possible quality standard.

R5 oil-lubricated rotary vane vacuum pumps from Busch Vacuum Solutions are standard (Fig. 2) in chamber machines and are used by all renowned manufacturers. They have been specially developed for packaging food and have proven themselves over decades. Through continuous advancement, these vacuum pumps have achieved the highest possible quality standard (Fig. 1).

-

Fig. 2: Functional model of a chamber packaging machine with visible rotary vane vacuum pump inside. Source: Busch Vacuum Solutions.

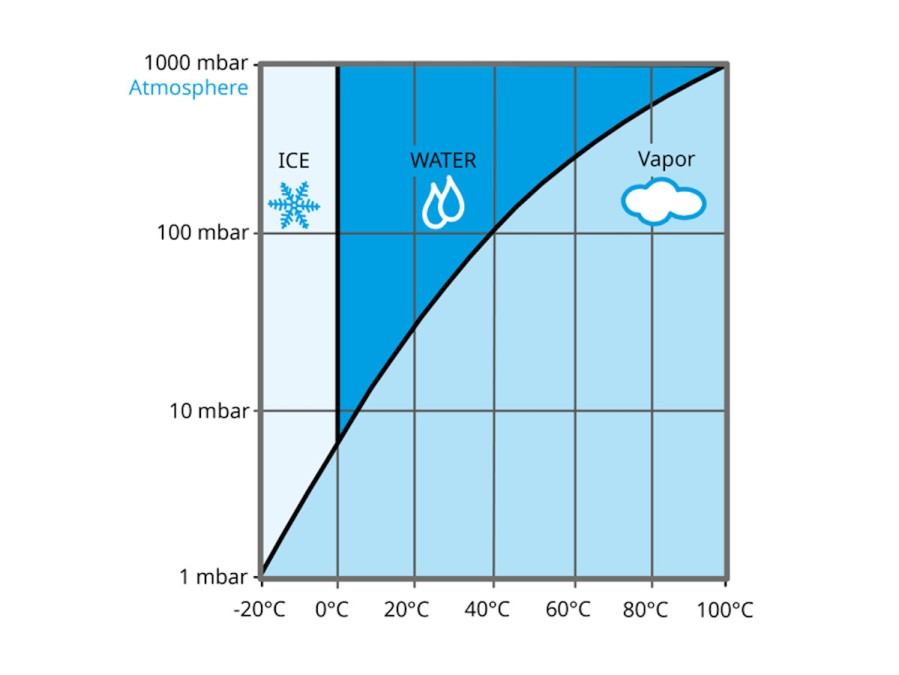

Fresh foods such as meat, sausage, fish, and cheese are usually vacuum packaged at a pressure of around five millibars. At this pressure, the oxygen content in the remaining residual air is so minimal that the activity of various microorganisms is prevented. This significantly increases the shelf life of the packaged products. However, such low pressures also cause water to start evaporating at low temperatures. While water at normal atmospheric pressure only evaporates or begins to boil at a temperature above 100 degrees Celsius, at a pressure of 30 millibar it starts to evaporate at room temperature. At a pressure of 8 millibar, water evaporates already at a temperature of 4 degrees Celsius – even in cooled rooms (Fig. 3).

-

Fig. 3: Change in the aggregate states of water as a function of temperature and pressure. Source: Busch Vacuum Solutions.

Recommendation for operation

In order to ensure the reliable and trouble-free operation of chamber machines, the following should be observed:1. Let the vacuum pump warm up before packaging

To do this, simply run the packaging machine five to ten times without any product and packaging bag. Make sure that the chamber is dry for this.

2. Use the service program regularly

Nowadays, most chamber machines have a service program. This program ensures that condensed water vapor that has mixed with the oil is removed from the vacuum pump. This program should be started at least once a week. Depending on the packaging machine, it takes between 10 and 20 minutes. The vacuum pump is brought to operating temperature so that the water in the vacuum pump evaporates again and is discharged.

3. Check oil level and oil quality weekly

A visual inspection should be carried out once a week to check that the oil quantity and quality are correct. This can be done quickly and easily through the oil sight glass. The oil in the vacuum pump should be colorless to yellowish and clear. If the level falls below the MIN mark on the oil sight glass, oil must be topped up. If the oil is milky and cloudy, this is a sign that water has mixed with the oil and formed an emulsion. The service program then needs to be run. If this has no effect on the visual condition of the oil, an oil change needs to be performed. Darkening of the oil is a sign that some substances, for example spices, have been deposited in the oil or that it has aged too much. An oil change also needs to be performed if this is the case.

4. Use suitable vacuum pump oils

The quality of the oil in vacuum pumps and the correct quantity play an important role in the packaging process and in protecting the pump. It is therefore essential to choose the correct oil to ensure the vacuum pump and thus the packaging machine function properly. Busch Vacuum Solutions has developed special oils for vacuum pumps in packaging machines. The VSA vacuum pump oil is suitable for packaging very moist products, since it has been designed for the extraction of air with a high water vapor level. For less moist food, the VSL vacuum pump oil can also be used. Both oils are food-grade synthetic oils with H1 approval. They also have a service life of up to four times longer than mineral oils. Busch also offers suitable oils for packaging with oxygen as a modified atmosphere.

5. Service your vacuum pump regularly

The vacuum pump in a chamber machine should be serviced regularly. The service intervals depend on the operating conditions, the number of packaging cycles, and the type of goods to be packaged. A reliable indicator of when an oil change needs to be performed is the visual condition of the oil, as described under point 3. When changing oil, the exhaust filter in the oil separator should always be replaced as well. For vacuum pumps with a pumping speed of 25 cubic meters per hour or more, the oil filter also needs to be changed. The sealing rings on the service openings should also be replaced in order to prevent leaks. For your convenience, Busch offers service kits for all R5 vacuum pumps, which contain all the necessary parts. Busch Vacuum Solutions offers a worldwide maintenance service so that this work can also be carried out by a service technician directly at the customer's premises. Different types of service contracts are available.

Observing these instructions will help to ensure trouble-free operation and a long service life for the vacuum pump, as well as optimum packaging results.