Secure Clamping of Small Panels with Vacuum

ASSTEC

Maulburg, Germany

|

June 15, 2021

ASSTEC Assembly Technology GmbH & Co. KG specializes in developing and creating ergonomic workspaces. Its range of products and services covers everything from the supply of individual components for the manufacture of assembly, testing and shipping work stations to the design and manufacture of individual one-piece-flow production cells for full-scale industrial production.

When producing tabletops and facing, or working with material to construct merchandise fixtures, chutes, drawers and shelving, ASSTEC normally uses high-pressure laminate (HPL) panels processed on a CNC router. These

panels are clamped on a vacuum table.

To generate the vacuum, ASSTEC relies on a

MINK claw vacuum pump from Busch. The vacuum pump generates a consistently high vacuum, enabling even small work pieces to be held securely.

About ASSTEC

The various departments based at ASSTEC's headquarters in Rottweil (Workshops, Tools, Design, Implementation) all work towards achieving efficiency in every aspect of production processes across all sectors of the manufacturing industry. They also offer a consultancy programme with special workshops on topics such as layout and material flow planning, reduction of tooling times, ergonomic work station design, and shop floor management.

In a nutshell, ASSTEC addresses anything that makes production quicker and more efficient, while also making work stations more ergonomic and secure. After working with its clients to develop a concept, ASSTEC uses full-size (1:1) cardboard engineering prototype models to perform tests. This step is followed by the design and production of the individual work stations (Fig. 1) and their equipment.

Holding panels

When working with panels, ASSTEC predominantly uses HPL in a range of thicknesses, which is then processed on a CNC router (Fig. 2). This router is also used to mill or engrave polycarbonate, other plastics and aluminium panels.

The manufacturer installed

four suction fans on the router. Each one of these suction fans supplied one of four quadrants, into which the entire machining table had been divided. Each quadrant measured 3,000 x 500 millimetres. This enabled the machine to securely

hold panels up to 2 x 3 metres in size. The vacuum generated by the suction fans was also strong enough to hold panels that covered one of the table's four quadrants. However, the holding force was too low for smaller work pieces, which meant they often slid across the table during processing.

In an attempt to counteract this flaw in the system, the company tried reducing the router's feed rate, though this solution was deemed to be insufficient. Marc Blessing, Managing Director at ASSTEC, therefore went looking for a better technical solution and spoke to the vacuum specialists from Busch Vacuum Solutions.

Busch vacuum solution and its benefits for the customer

They recommended to use a

MINK MV claw vacuum pump, which would be able to replace the four existing suction fans.

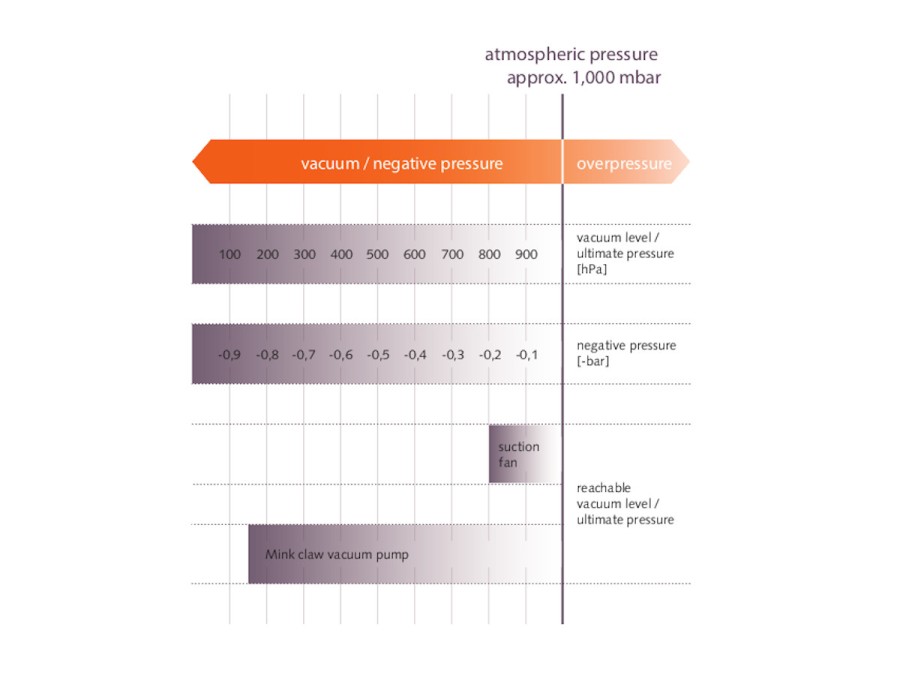

ASSTEC decided to implement this solution, and then replaced the four suction fans with one MINK MV claw vacuum pump (Fig. 3), which now generates enough pumping speed to cover all four vacuum sectors – the entire machining table. What's more, their vacuum level of 150 millibars (absolute) is significantly higher than the vacuum level of 800 millibars (absolute) of the old suction fans (Fig. 4).

MINK MV claw vacuum pumps are nearly maintenance-free.

MINK MV claw vacuum pumps are nearly maintenance-free. Only the oil in the gearbox needs to be changed every two years. Thanks to the high vacuum level, even small work pieces can now be clamped securely during machining.

The physical basis of clamping with vacuum

The reason for using a vacuum table for clamping is of course to allow a flat work piece to be held securely during the machining process. Another advantage is that no mechanical clamping elements are needed, which means no time is wasted on attaching components and no pressure marks are left on the work pieces. A combination of various factors determines whether a work piece is held securely or not. In physical terms, it isn't actually the vacuum that holds the work pieces, but rather atmospheric pressure. The vacuum system simply provides sufficient negative pressure on the opposite side to allow the atmospheric pressure to apply its full effect. From a technical perspective, the pressure between the work piece and the machining table or its supporting surface is reduced during clamping because air is extracted.

Pressure, surface, holding force In physics, pressure is defined as the force that affects a specific area – thereby making it a function of force and area (Fig. 5). The example below demonstrates how this function is calculated:

An HPL panel is placed on the CNC router's vacuum table ready for machining. Measuring 500 x 3,000 millimetres, it exactly matches the size of one of the quadrants. The other three quadrants are separated from the vacuum supply by shut-off valves.

Calculating the holding force with a suction fan (800 millibars (abs.))

Atmospheric pressure: 1,000 mbar |

Negative pressure produced by suction fan: 800 mbar |

Dimensions of wooden panel: 3,000 x 500 mm |

Supporting surface = clamping surface |

3,000 x 500 mm = 1,500,000 mm2 = 1.5 m2 |

1,000 mbar – 800 mbar = 200 mbar = 20,000 Pa [N/m2] |

Holding force F = p x A F = 20,000 N/m2 x 1.5 m2 = 30,000 N |

This means that the pressure differential of 200 millibars between atmospheric pressure and the negative pressure generated by the suction fan leads to a holding force of 30,000 N. The HPL panel is therefore pressed onto the machining table with a weight of three tons.

If the user wants to clamp a smaller HPL panel for machining, the holding force decreases using the same formula. In this case, it is assumed that the free space on the vacuum table is air-tight and covered with panel material or film.

If an HPL panel with the dimensions of 150 x 150 millimetres is clamped, the holding force is only 450 N, which corresponds to a weight of 45 kilograms pressing the panel onto the machining table. Depending on what the user is doing to the panel, a holding force of 450 N may be too small to make sure the panel is held securely.

If this small HPL panel is now clamped onto the machining table under the same conditions with a MINK claw vacuum pump, the holding force more than quadruples. The reason for this is the increased pressure differential between atmospheric pressure and the vacuum of 150 millibar generated by the vacuum pump. In mathematical terms, the force of 450 N when clamping with a suction fan increases to 1,912 N when clamping with the MINK vacuum pump. The weight applied to the panel increases from 45 to 191 kilograms.

As a result, we can conclude that the smaller an HPL panel is, the higher the vacuum pump's pressure differential or vacuum level has to be.

These calculations only apply when the surfaces on the vacuum table that are not covered by the panel being processed are covered so they are air-tight. If this is not the case, “leak air” is sucked into the system. If the vacuum pump is large enough and its pumping speed is high enough, it will still achieve the required vacuum level. If vacuum pumps are too small, however, there is a risk that the “leak air” sucked into the system will have a negative effect on the vacuum level and, as a result, the holding force as well.

ASSTEC has been using the MINK claw vacuum pump since early 2018. Managing Director Marc Blessing emphasizes that they have not experienced any clamping problems since then, and that

the vacuum pump delivers a constantly high vacuum level to their utmost satisfaction.

Maulburg, Germany

|

June 15, 2021