Galeon is one of the leading European manufacturers of luxury yachts. It operates two production facilities near Gdańsk, Poland.

Galeon motor yachts are up to 25-metre long, with main components such as the hull, deck and the superstructure constructed of glass fibre reinforced plastic. This material is either hand-laminated or produced by a vacuum infusion process. These components must withstand high stresses, and be both visually and structurally perfect. The vacuum system used for the vacuum infusion process must operate reliably and be resistant to resin vapour.

In July 2013 Galeon opted for a Busch vacuum system with a MINK claw vacuum pump. This system supplies the entire laminates division with vacuum, allowing high-quality components to be produced.

Modern Vacuum Technology for Resin Infusion in Yacht Construction

Galeon

The vacuum infusion process

When a new model is under development, a prototype is first created from which negative moulds are made to allow components to be laminated. The largest components made by the vacuum infusion process are the hull, deck and the superstructure. In the past, Galeon used vacuum ejectors mounted directly to the individual moulds.In early 2013, production increases planned for the future initiated a project to introduce a more effective and reliable vacuum system which would supply as many moulds as possible simultaneously.

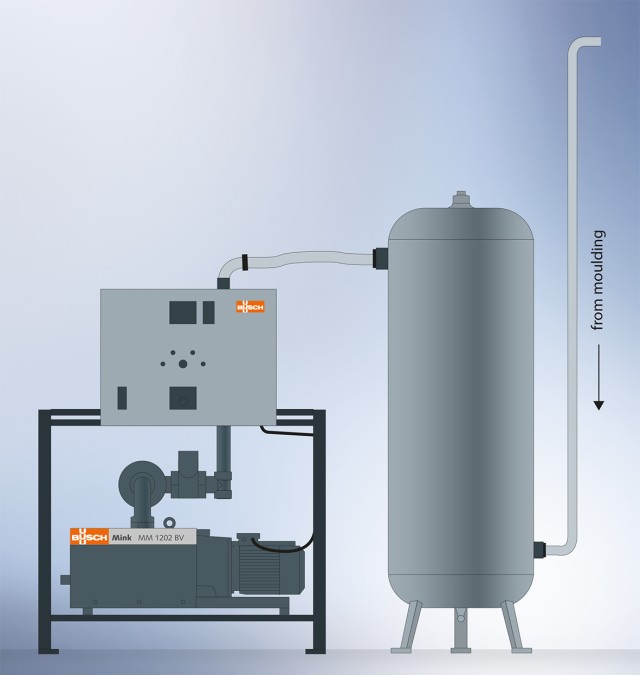

After initial discussions with Busch, a Busch vacuum specialist was sent to the Galeon site to assess the project requirements. Busch then proposed a centralised vacuum supply system powered by a MINK claw vacuum pump, with a vacuum reservoir and controller unit. Busch also provided consultation services for the construction of the vacuum pipework in the laminating area. The vacuum network is equipped with vacuum connections in the immediate vicinity of every mould, to permit air to be evacuated from the moulds as required.

The MINK claw vacuum pump is dimensioned to allow the moulds for two boat hulls and three smaller components to be evacuated simultaneously. If future production output increases, a second identical claw vacuum pump may be installed, doubling the system output. The controller and system frame are already configured for this expansion.

-

Fig. 2: Mould for manufacturing a boat hull

Component manufacture takes between five and seven days, from the application of the gelcoat to the removal of the finished component from the mould.

- The mould is first waxed and the gelcoat resin is applied.

- After the gelcoat resin has hardened few layers of glass fibre are applied in hand lay-up process.

- Then numbers of dry glass fibre are placed into the mould. Their number depends of size of the part.

- When this process is complete the mould is enclosed in vacuum foil, the resin inlets are inserted and the mould edges sealed.

- The mould is then connected to the vacuum system and air is extracted. The vacuum pump runs continuously at this time to allow any leaks to be detected and sealed by hand. Sensors attached to the vacuum connection indicate when the required vacuum level has been achieved and maintained, showing that the mould is completely airtight. his procedure ensures that the mould is free of leaks and the vacuum foil has been correctly applied, and takes between one and two hours.

- Between 200 and 600 kg of resin is then sucked into the mould, depending on mould size. The vacuum in the mould ensures that the resin is evenly distributed, and inhibits the formation of air bubbles. A further one to two hours are required to allow the resin to reach every part of the mould.

- During this process the vacuum pump runs continuously in "automatic" mode. This means the vacuum pump creates a predetermined vacuum level in the upstream reservoir, then turns itself off. Air extracted from the mould flows into this reservoir. If the reservoir pressure rises above a certain level, the vacuum pump is switched back on. The vacuum pump thus runs intermittently, saving energy.

-

Fig. 3: Busch MINK claw vacuum pump for evacuating moulds prior to resin infusion

During the infusion process the mould is also monitored by Galeon personnel to ensure that any leaks occurring are rectified immediately. This is of the utmost importance, as Galeon wishes to offer its customers products of the highest possible quality.

Product quality and system reliability were the primary reasons for the decision in favour of Busch and MINK claw vacuum technology.

Product quality and system reliability were the primary reasons for the decision in favour of Busch and MINK claw vacuum technology.

About MINK dry claw vacuum pumps

MINK claw vacuum pumps are dry, which means extracted air cannot make contact with operating fluids. Resin vapour can react with operating fluids in conventional vacuum pumps, reducing their lubricating properties and diminishing system output.In addition, MINK vacuum pumps are contact-free, not subject to wear, and require almost no maintenance. After two years of operation Busch technicians replaced the inlet filter and changed the gearbox oil. An inspection of the vacuum pump revealed no wear or damage, and the internal components were free of particles and condensed resin vapour depos.

The decision in favour of MINK claw vacuum technology is considered by Galeon to be correct, as Busch consultation services and support provided during the installation process were first class. An additional advantage is the simple system expansion of the Busch solution, as Galeon is certain that production will increase in the future.

About Galeon

Galeon was founded in 1982, and from the outset produced motor boats of up to 25 m. It is still managed by the founder, and has become one of the leading luxury yacht manufacturers in Europe. The company now employs over 500 staff at two production facilities near Gdańsk, Poland. Renowned marine architects design the boat series, which are produced as basic models to be customised to suit the preferences of individual clients.

Galeon was founded in 1982, and from the outset produced motor boats of up to 25 m. It is still managed by the founder, and has become one of the leading luxury yacht manufacturers in Europe. The company now employs over 500 staff at two production facilities near Gdańsk, Poland. Renowned marine architects design the boat series, which are produced as basic models to be customised to suit the preferences of individual clients.