About Duni Group

Duni Group, with headquarters in Sweden, owns the Duni Poland Sp. z o.o. production plant. Duni can look back on over 60 years of company history. It all began in Malmö, Sweden, where the first waxed paper cups and napkins from thin, coated crepe paper were made in 1949. Nowadays, Duni produces packaging and takeaway solutions like tableware for restaurants and end customers. Duni occupies the leading position in the central and northern European market with 2,300 employees in 23 countries. Duni Poland in Posen has 400 employees; the plant focuses on producing paper napkins and printed paper plates. The process of napkin production

The various paper types and grammages for napkin production are delivered on rolls. The rolled up paper runs through one of several automated production lines in which the napkins are produced and prepared for dispatch. Whether the material is printed or imprinted, at the end of the production line, there is always a machine that cuts the paper several times and folds it up to three times before the finished napkins are packaged. These cutting and folding machines can be set up to make the various formats and folds possible. Vacuum is needed to transport and hold the paper as it is moved through the rollers, and cutting and folding tools to the end of the line where it comes out as finished napkins. In the past, liquid ring vacuum pumps were installed on three of these cutting and folding machines to generate the necessary vacuum. These vacuum pumps were high-maintenance because the water used as the operating fluid needed to be refilled every day. As oil is used to lubricate the knife of the cutting tools, it is impossible to prevent the extracted air from containing oil particles. This causes oil to mix with the water in the vacuum pumps. The water used as operating fluid in each of the three identical liquid ring vacuum pumps circulated in the system. Being contaminated with oil it had to be completely replaced and disposed of regularly. The engineer responsible for production engineering no longer wanted to tolerate this situation. Especially because the noise emissions of these liquid ring vacuum pumps, which were in the immediate vicinity of the workstations, were so high. He also tried to find a solution that consumed less energy.

Busch vacuum solution and its benefits for the customer

Experiments with dry-running rotary vane vacuum pumps were disappointing because the extracted air corroded the graphite vanes due to the oil it contained.

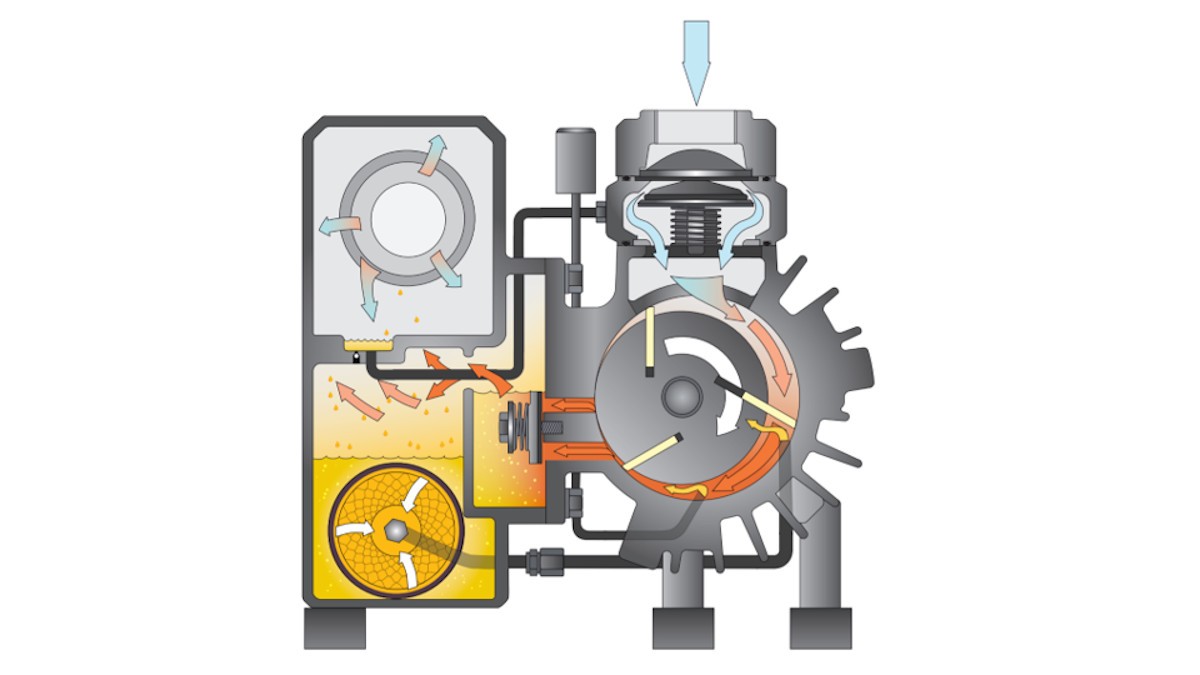

The power consumption was reduced by 55 percent.

R 5 rotary vane vacuum pumps (Fig. 2) have been the standard solution for vacuum generation in various applications for several decades. Thanks to their internal oil circulation, they can handle liquid particles that have been sucked into the vacuum pump. The oil ensures excellent sealing and lubrication of the compression chamber, making it possible to achieve a high vacuum level of 0.1 mbar. This value corresponds to a 99.99 percent vacuum. Due to their design, liquid ring vacuum pumps can achieve an ultimate pressure of 33 mbar (= 96.7 percent) under ideal operating conditions. Dry-running rotary vane vacuum pumps work according to the same compression principle as oil-lubricated rotary vane vacuum pumps. However, they do not use oil, which results in a loss in ultimate pressure. This means that these types of vacuum pumps in comparable sizes only supply a vacuum level of 200 mbar (= 80 percent). The high vacuum level of 0.1 mbar of R 5 rotary vane vacuum pumps now provides sufficient output reserves for paper handling in the cutting and folding machines. This means that format changes or leaked air do not affect the provision of constantly high pumping speeds and availability of the same vacuum level.