Plastics processing with vacuum and overpressure

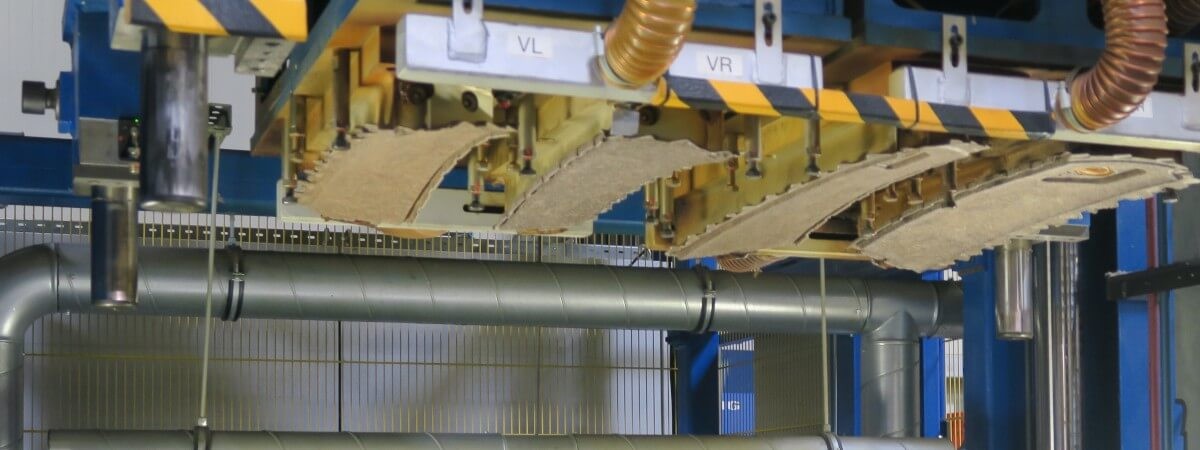

Without vacuum, nothing works in plastics processing. Vacuum pumps and systems from Busch are used in all process steps. From the production of the raw granulate and plastic extrusion to the manufacture of the finished plastics part. All the way to recycling.

Let us guide you in finding the perfect solution for your process requirements.

We have looked for an optimization for the existing vacuum supply on two laminating systems and realized a significant cost reduction with a simple solution.

| MINK | R5 | DOLPHIN | COBRA | SAMOS | HUCKEPACK | VACTEST | TAPIR | |

| Extruder compounding | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Extruder sheet/film | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Extruder profile | ✓ | ✓ | ✓ | ✓ | ||||

| SSP recycling | ✓ | ✓ | ✓ | ✓ | ||||

| Material drying | ✓ | ✓ | ✓ | ✓ | ||||

| Vacuum calibration | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| Thermoforming | ✓ | ✓ | ✓ | ✓ | ||||

| Injection molding | ✓ | ✓ | ✓ | ✓ | ||||

| Resin transfer molding (RTM) | ✓ | ✓ | ✓ | ✓ | ||||

| Vacuum bagging | ✓ | ✓ | ✓ | ✓ | ||||

| Pneumatic conveying | ✓ | ✓ | ✓ | ✓ | ✓ |

Get your turnkey vacuum system now!

With its impressive track record, our R5 vacuum pump has clocked an astounding 200,000+ hours of service with minimal maintenance since it was put into operation in 1988. Remarkably reliable even under the strain of running two shifts a day (or more sometimes) for 14.5 hours - 4,422 annually for 34 years! This resilient machine truly is the workhorse we can always count on.