How is it calculated?

The initial purchase price of a vacuum solution is only a fraction of the total expenses incurred over its entire lifetime. That is why it is important to understand the true cost of ownership to maximize efficiency and minimize costs.Let Busch help you make an informed decision when purchasing vacuum equipment. Together, we conduct a comprehensive analysis of your requirements and gain an understanding of possible long-term costs.

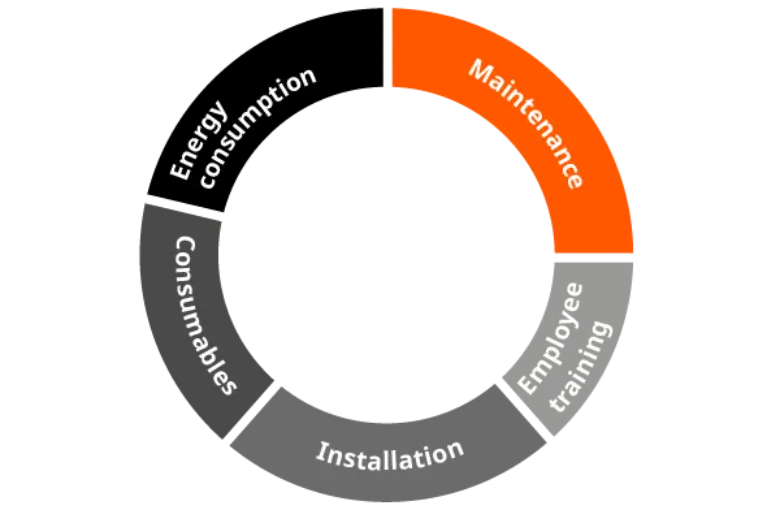

We will evaluate the initial purchase cost, energy efficiency, and maintenance and training needs. This enables us to find a vacuum solution that fits your needs best while keeping budget constraints and operational requirements in mind.

Explore our comprehensive guide and solutions for calculating the total cost of ownership of vacuum equipment!