What is the role of vacuum in coating?

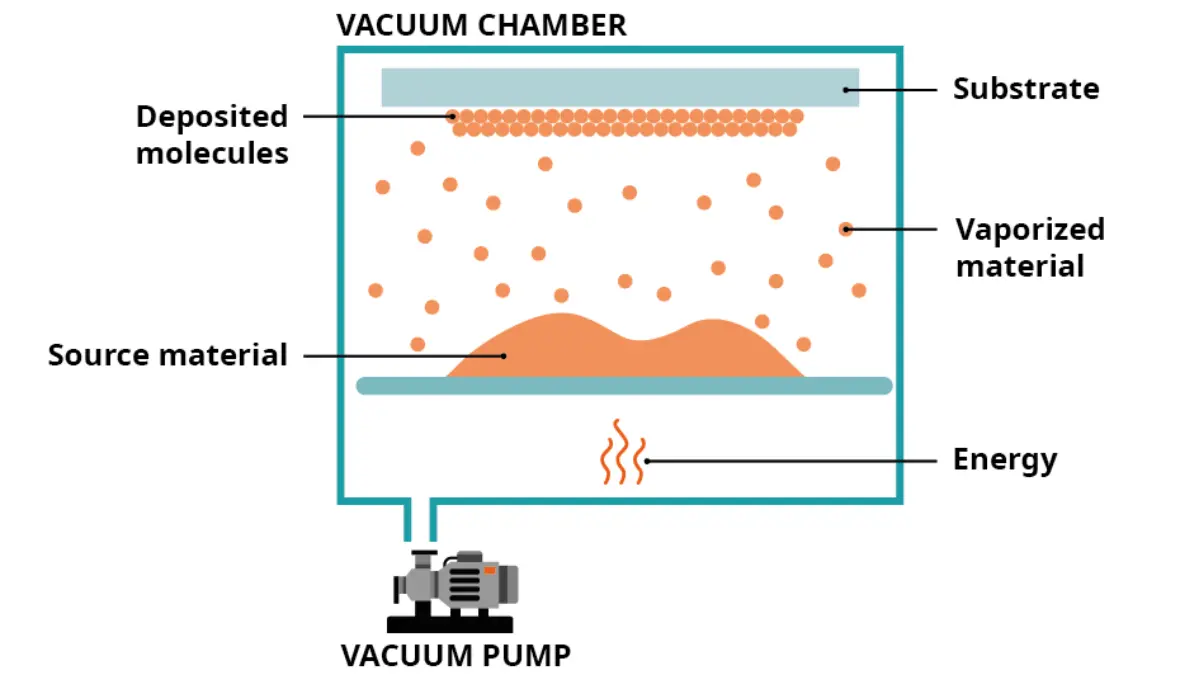

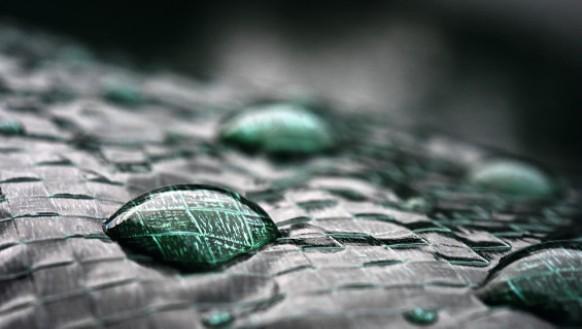

Vacuum coating is carried out in a vacuum chamber. Medium or high vacuum is applied to the chamber for the evacuation of any contaminants, such as oxygen and nitrogen. This creates a clean environment.Depending on the vacuum coating process, a reaction gas or solid raw material is vaporized and deposited on the surface of a substrate. Vacuum coating is used to form layers ranging from a thickness of one atom up to a few millimeters. Multiple layers of different materials can be combined to form optical coatings. This type of coating is designed to manipulate the transmission, reflection and absorption of light in order to enhance optical performance or achieve specific optical properties.