Moving bed process

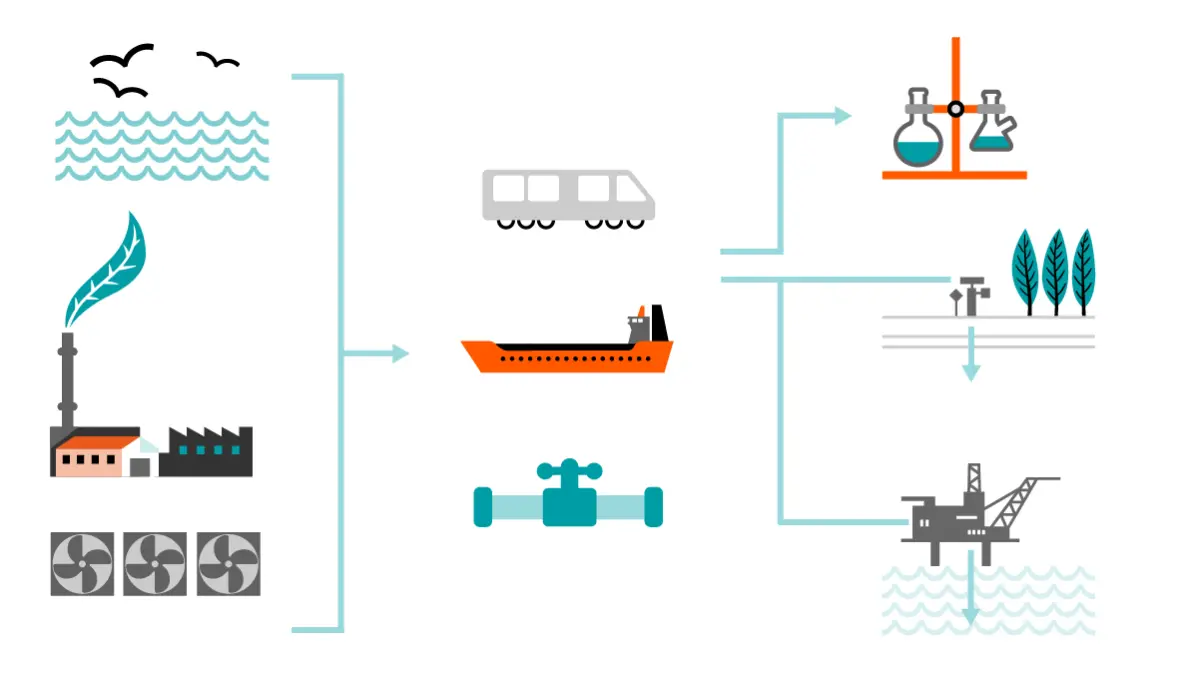

The moving bed process of carbon capture consists of three stages: the

adsorption reactor, the

desorption reactor, and the

adsorbent dryer. In this process, the CO

2 is collected by

solid sorbents. These are balls made of a porous material and saturated in amine solvent, which circulate through the three areas of the system.

Adsorption reactorThe process begins in the adsorption reactor. Here, the flue gas from the industrial process is introduced, and the CO

2 is adsorbed by the sorbent. Although the method is different, this step works exactly the same as in the amine scrubbing process: The carbon dioxide dissolves in the amine solvent and is trapped.

Desorption reactorThe CO

2-laden solid sorbent then moves to the desorption reactor. Steam is blown into the reactor and condenses on to the solid sorbent, releasing the CO

2, which can then be extracted.

A vacuum pump connected to the outlet of the desorption reactor suctions the CO

2. The gas travels through the vacuum pump and enters the collection vessel at the outlet. From there, it can be transported for reuse or storage.

Adsorbent dryerNext, the solid sorbent, now saturated with moisture, moves to the adsorbent dryer. A blower pushes warm air into the dryer, reducing its moisture content. The solid sorbent is then discharged from the adsorbent dryer, ready to be reused.

Vacuum swing adsorption (VSA)

Vacuum swing adsorption (VSA), also known as pressure swing adsorption (PSA) or vacuum pressure swing adsorption (VPSA), is a CO

2 separation process that follows the same general steps as the moving bed process:

adsorption,

desorption and

regeneration.

AdsorptionFirst, the flue gas is passed at high pressure through what is known as an adsorption bed. This is kind of filter made of a solid sorbent: a porous material that can either be amine-based, just like the other capture methods, or can be another compound such as activated carbon or zeolite. It selectively captures the CO

2 molecules while allowing other gases to pass through.

DesorptionAfter the CO

2 has been separated from the rest of the flue gas and the adsorbent bed is saturated, vacuum is applied in the chamber. As a result, the pressure on the captured carbon dioxide molecules is lowered, allowing them to detach, or desorb, from the adsorbent bed and return to a gas state. When the temperature is increased at the same time, the desorption process is even more efficient.

RegenerationJust like in the amine scrubbing process, this process to release the carbon dioxide also regenerates the amine-based adsorbent bed, allowing it to be reused.

The molecules can subsequently be recaptured, now at a high purity, for transportation or storage.