Operating Principle

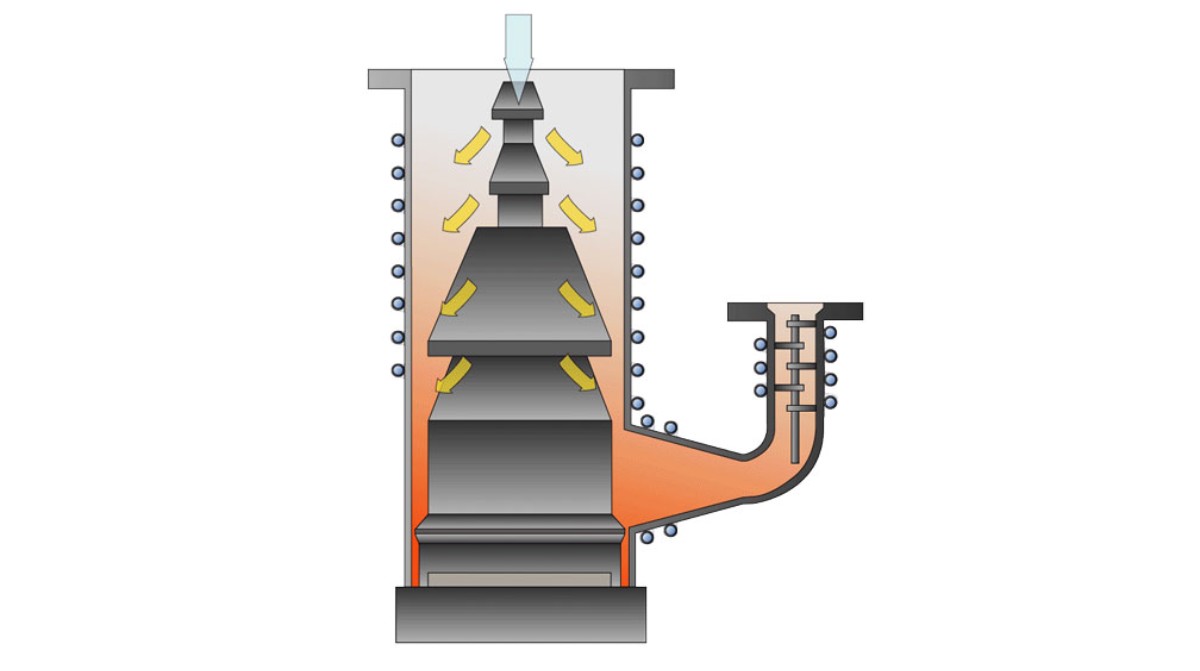

The basic component of diffusion vacuum pumps is a cylindrical pump unit with a heatable bottom. Oil is used as a fluid and is heated up. The vapor from this oil rises into the nozzle system. It then passes through several vapor jet stages and out of this system under high pressure.

The molecules in the process gas are caught by these vapor jets and carried downwards, towards the outlet of the backing pump. The oil vapor condenses on the inner surface of the water-cooled pump unit and is directed back to the bottom.

The molecules in the process gas are caught by these vapor jets and carried downwards, towards the outlet of the backing pump. The oil vapor condenses on the inner surface of the water-cooled pump unit and is directed back to the bottom.