COBRA Semicon

Dry screw vacuum pumps

COBRA Semicon dry screw vacuum pumps are the ideal choice for all demanding processes in the production of photovoltaic cells, flat screens, semiconductors, and in numerous industrial coating applications.

The operating principle of COBRA Semicon is based on our state-of-the-art screw technology. With their patented self-balancing screws, they set new standards in terms of efficiency.

COBRA Semicon combine large throughputs with high vapor and particle tolerance. Particle-laden media can therefore be evacuated without any problems.

The oil- and contact-free operating principle ensures low maintenance requirements, low operating costs and a long life cycle.

The compact dimensions of COBRA Semicon make installation easy – even in confined spaces.

Operating principle

Inside COBRA Semicon dry screw vacuum pumps, two screw rotors rotate in opposite directions. The pumped medium is trapped between the cylinder and the screw chambers. There, it is compressed, and transported to the outlet. During this process, the screw rotors do not come in contact with each other or the cylinder.COBRA BA

- Advanced screw design

- Dry and contact-free operating principle

- Unique “flying bearing” design

- Cantilever construction

- Compact design

- Effective air cooling

- Optional frequency converter

Benefits of the COBRA BA series

COBRA BA are proven dry screw vacuum pumps perfectly suited for demanding processes such as sterilization, metallurgy, gas recovery or furnace applications.

The patented self-balancing screw design ensures lowest vibration levels and quiet operation.

COBRA BA vacuum pumps feature a bell-shaped cantilever construction: The twin rotor with variable pitch screws is mounted only on the motor side. Thanks to the unique “flying bearing” design, inlet bearings are unnecessary. Therefore, the pumped medium does not come in contact with the bearings. This ensures clean vacuum generation and allows to fully recover the pumped medium.

COBRA BA vacuum pumps are characterized by an efficient air cooling.

A directly mounted, canned motor makes the dimensions of the COBRA BA series very compact.

All COBRA BA products

COBRA BC

- Advanced screw design

- Dry and contact-free operating principle

- Unique “flying bearing” design

- Cantilever construction

- Compact fit-in-place design

- Direct water cooling

- Fully open communication protocol

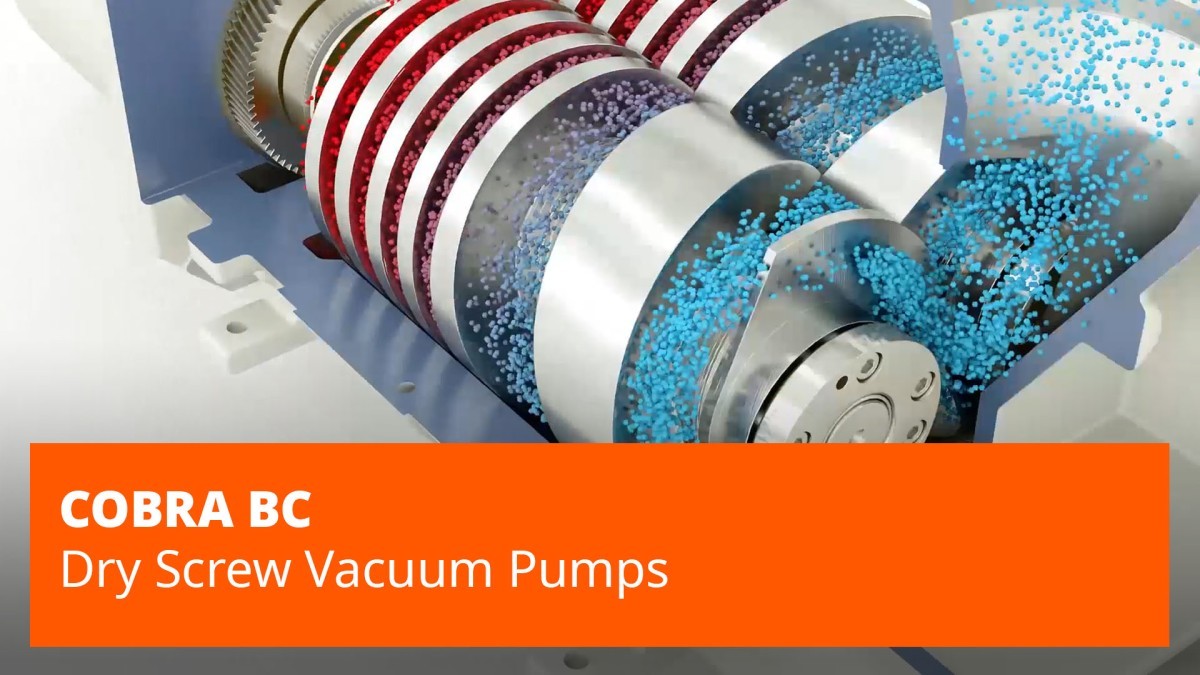

Video: How COBRA BC vacuum pumps work

Benefits of the COBRA BC series

COBRA BC vacuum pumps are perfectly suited for tasks in load lock and transfer chambers. Further applications are among others metrology, lithography, physical vapor deposition, rapid thermal annealing and silicon etch.

The patented self-balancing screw design ensures lowest vibration levels and quiet operation.

The screws of COBRA BC vacuum pumps are manufactured from a single-piece casting avoiding any gaps. This makes an ingress of process fluids or particles impossible. Thus, corrosion and deposition are prevented.

COBRA BC vacuum pumps feature a bell-shaped cantilever construction: The twin rotor with variable pitch screws is mounted only on the motor side. Thanks to the unique “flying bearing” design, inlet bearings are unnecessary. Therefore, the pumped medium does not come in contact with the bearings. This ensures clean vacuum generation and allows to fully recover the pumped medium.

COBRA BC series vacuum pumps use efficient direct water cooling. An even temperature distribution throughout the pump body is therefore maintained. Moreover, thermal stability during the process is ensured.

The fully open communication protocol (Modbus TCP-IP) allows to control all functionalities. This includes idle modes and variable speed drive. The communication protocol can easily be adapted to a specific network protocol using standard interface components.

A directly mounted, canned motor makes the dimensions of the COBRA BC series very compact. Due to their fit-in-place design, they can be easily and quickly retrofitted to existing systems.

All COBRA BC products

COBRA DS

- Advanced screw design

- Dry and contact-free operating principle

- Excellent powder handling

- Effective indirect water cooling

- Compact fit-in-place design

- High pumping speed for the discharge of hydrogen

- High-efficiency motor

- Sizes with integrated vacuum booster available

Benefits of the COBRA DS series

COBRA DS dry screw vacuum pumps are the ideal vacuum generators for demanding processes. Even under conditions in which a high hydrogen throughput is required. They are therefore perfectly suited for chemical vapor deposition, rapid thermal processing or atomic layer deposition.

Various sizes of the COBRA DS series feature an integrated high-performance vacuum booster. This combination of backing pump and vacuum booster allows to achieve increased pumping speeds and ultimate pressures.

The patented self-balancing screw design ensures excellent powder handling and high uptime.

The screws of COBRA DS vacuum pumps are manufactured from a single-piece casting avoiding any gaps. This makes an ingress of process fluids or particles impossible. Thus, corrosion and deposition are prevented.

COBRA DS series vacuum pumps use effective, indirect water cooling. As a result, the temperature distribution throughout the pump body can be controlled. A response to process variations is possible at any time.

Due to their fit-in-place design, COBRA DS can be easily and quickly retrofitted to existing systems.