- High volumetric efficiency

- Integrated bypass valve

- Dry and contact-free compression

- Minimal maintenance

- Adaptable to all types of backing pumps

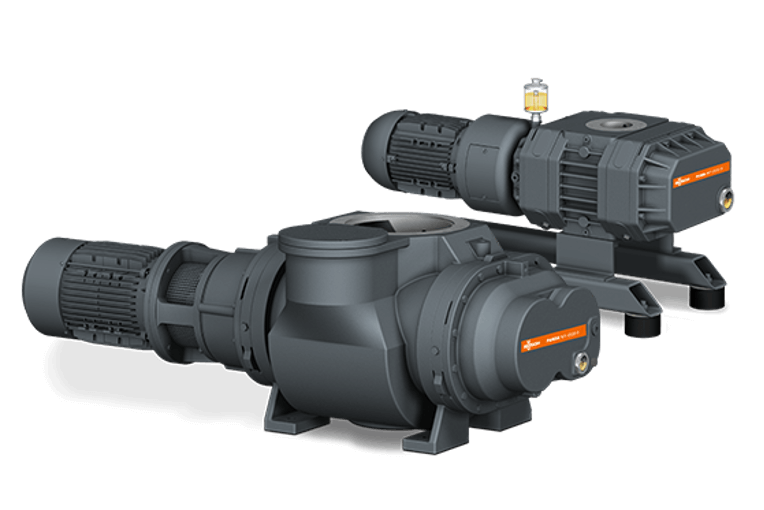

PANDA/PUMA

Vacuum boosters

PANDA/PUMA vacuum boosters increase the pumping speed and ultimate pressure of vacuum pumps. They can boost the performance of vacuum systems by up to a factor of ten.

In combination with backing pumps, PANDA/PUMA are perfectly suited for all applications that require high pumping speeds at a defined working pressure.

Busch vacuum boosters are available in a large number of sizes. This allows pumping speed and ultimate pressure to be tailored exactly to the process conditions.

In contrast to PUMA vacuum boosters, PANDA vacuum boosters come with a bypass valve as standard. Both PUMA/PANDA series are compatible with a variable speed drive.

Operating principle

Within the housing of PANDA/PUMA vacuum boosters, two lobes rotate synchronously. Due to the special profile of the lobes and their precise manufacturing, they do not come in contact with each other or the housing. Thus, no lubricants or operating fluids are required in the process chamber.During the rotation of the lobes, gas is transported between the lobes and the housing into the backing pump.

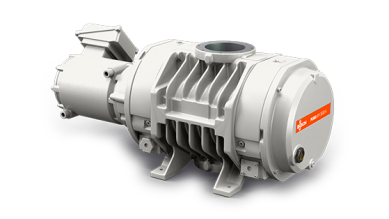

PANDA WV

Benefits of the PANDA WV series

PANDA WV significantly increase the performance of all types of backing pumps in the rough, medium and high vacuum range.

They are equipped with a bypass valve as standard. It reliably protects the vacuum boosters against overloading or overheating and allows them to be used for high differential pressures.

PANDA WV vacuum boosters operate completely contact-free and without any operating fluids in the process chamber. Maintenance is therefore limited to a minimum. Additionally, PANDA WV vacuum boosters have an exceptional volumetric efficiency and low energy consumption. All this leads to low operating costs.

PANDA WV can be flanged directly onto the backing pump or at any other position in the system. They are also compatible with a variable speed drive.

All PANDA WV products

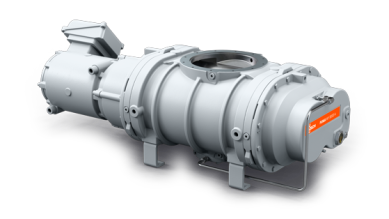

PUMA WY

- Variable speed drive available

- Dry and contact-free compression

- Adaptable to all types of backing pumps

- Minimal maintenance

- High volumetric efficiency

- Leak-tightness (> 1x10-6 mbar x l/s)

- GGG40 housing for high mechanical and chemical resistance

Benefits of the PUMA WY series

PUMA WY significantly increase the performance of all types of backing pumps in the medium and high vacuum range. They have been specially designed for semiconductor processes.

Thanks to a directly flange-mounted water-cooled motor, PUMA WY vacuum boosters are leak-tight to the atmosphere. They are perfectly suited to handle aggressive or toxic gases.

PUMA WY vacuum boosters operate completely contact-free and without any operating fluids in the process chamber. Maintenance is therefore limited to a minimum. Additionally, PUMA WY vacuum boosters have an exceptional volumetric efficiency and low energy consumption. All this leads to low operating costs.

PUMA WY can be controlled using a pressure switch. The pressure switch activates the vacuum booster when it has achieved the optimum working pressure. Alternatively, PUMA WY are available in versions with variable speed drive.

Having no coupling between motor and housing, PUMA WY are compact. They can be flanged directly onto the backing pump or at any other position in the system.

All PUMA WY products

PANDA WZ

- High volumetric efficiency

- Integrated bypass valve

- Leak-tightness (> 1x10-6 mbar x l/s)

- Dry and contact-free compression

- Adaptable to all types of backing pumps

- Minimal maintenance

Benefits of the PANDA WZ series

PANDA WZ significantly increase the performance of all types of backing pumps in the medium and high vacuum range. They have been specially designed for semiconductor processes.

Thanks to a directly flange-mounted water-cooled motor, PANDA WZ vacuum boosters are leak-tight to the atmosphere. They are perfectly suited to handle aggressive or toxic gases.

Having no coupling between motor and housing, PANDA WZ are compact. They can be flanged directly onto the backing pump or at any other position in the system.

PANDA WZ vacuum boosters operate completely contact-free and without any operating fluids in the process chamber. Maintenance is therefore limited to a minimum. Additionally, PANDA WZ vacuum boosters have an exceptional volumetric efficiency and low energy consumption. All this leads to low operating costs.

PANDA vacuum boosters are equipped with a bypass valve as standard. It reliably protects the vacuum boosters against overloading or overheating and allows them to be used for high differential pressures. Additionally, PANDA WZ are compatible with a variable speed drive.

All PANDA WZ products

PUMA WP

- Variable speed drive available

- Dry and contact-free compression

- Adaptable to all types of backing pumps

- Minimal maintenance

- High volumetric efficiency

- GGG40 housing for high mechanical and chemical resistance

Benefits of the PUMA WP series

PUMA WP significantly increase the performance of all types of backing pumps in the rough and medium vacuum range.

PUMA WP can be controlled using a pressure switch. The pressure switch activates the vacuum booster when it has achieved the optimum working pressure. Alternatively, PUMA WP are available in versions with variable speed drive.

PUMA WP vacuum boosters operate completely contact-free and without any operating fluids in the process chamber. Maintenance is therefore limited to a minimum. Additionally, PUMA WP vacuum boosters have an exceptional volumetric efficiency and low energy consumption. All this leads to low operating costs.

PUMA WP can be flanged directly onto the backing pump or at any other position in the system.