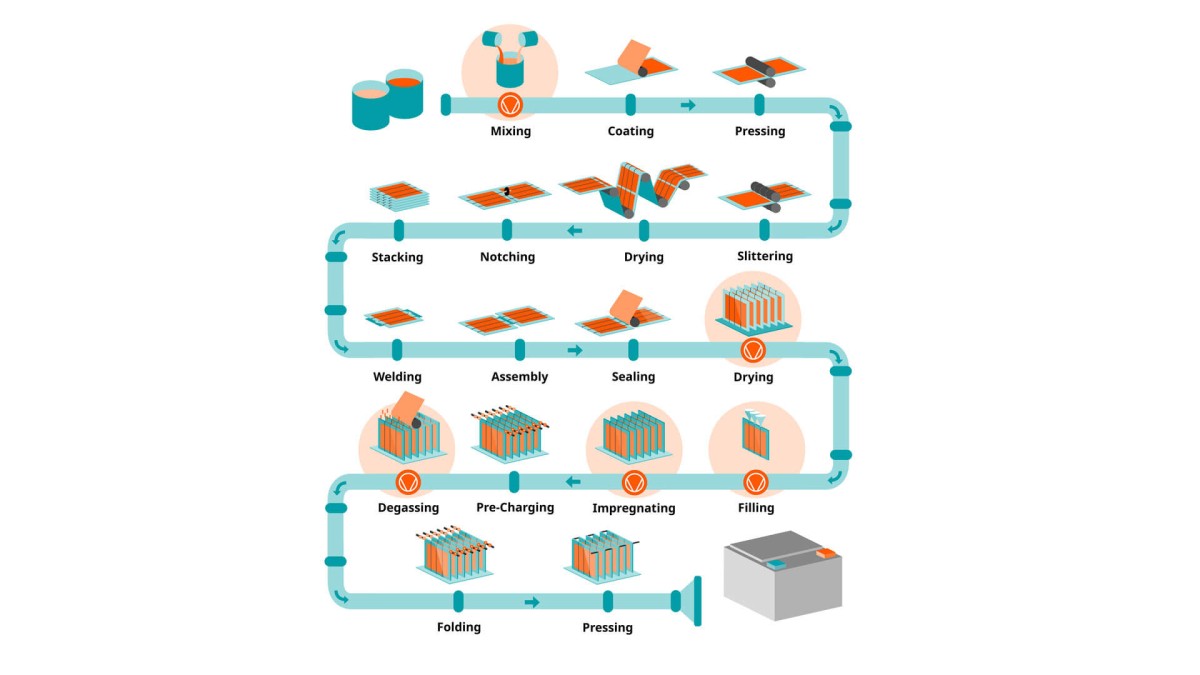

Lithium battery manufacturing

Vacuum solutions for the lithium-ion battery manufacturing process.

Lithium-ion batteries are at the heart of e-mobility. They can currently store more charge per unit of mass than other battery types – and make reasonable ranges possible.

Key processes during their manufacture are performed under vacuum. Our vacuum solutions are operated at major lithium-ion battery production sites the world over. They are renowned for their reliability in all stages of the lithium-ion battery production.

From mixing, drying, filling, degassing up to sealing. Without vacuum, many steps wouldn’t even be possible.

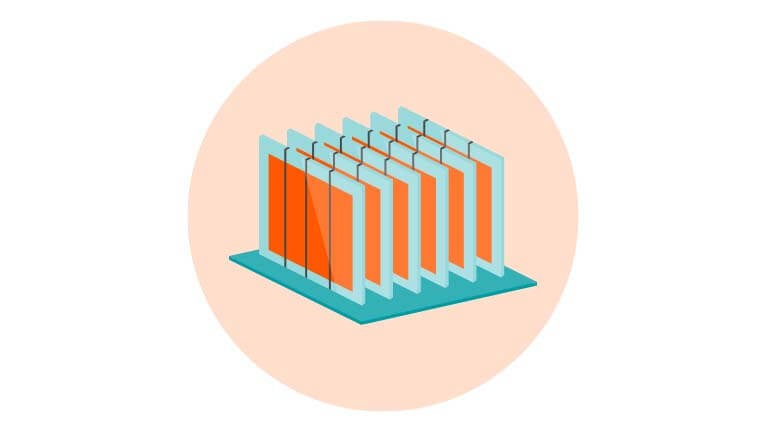

Impregnating of the lithium-ion battery cell

The contact between the electrode and electrolyte is essential for the function and efficiency of the battery cell.Vacuum assists this process to ensure that contact is without voids.

Matching products: R5 RA, COBRA NC/NX

Our matching products

Our vacuum solutions are operated at major lithium-ion battery production sites. The world over. And are renowned for their reliability. In all stages of the lithium-ion battery production.Product details

R5 RA

COBRA NC/NX

MINK MM/MV

- Latest dry claw vacuum technology

- Nearly maintenance-free

- Low energy consumption

Learn more aobut:

- MINK MM

- MINK MV

Get your turnkey vacuum system now!

The Busch promise

Products

Wide range of different vacuum technologies perfectly suited for all vacuum-assisted stages of lithium-ion battery production

IATF

Manufacturing in IATF-certified plants (International Automotive Task Force 16949: 2016)

Systems

Extensive centralized systems building competence

ARPQP

Unique support according to IATF standards with our exclusive ARPQP service

Savings

Up to 55% energy savings with our Busch solutions