Busch Genuine Vacuum Pump Vanes

The most important part of your rotary vane vacuum pump. Rely on Busch genuine vacuum pump vanes made of carbon fiber composite, glass fiber or graphite for optimum performance.

Busch vanes article lists

Why Busch Genuine Vacuum Pump Vanes?

The perfect vanes for your Busch pump

Our vacuum pump vanes have been specially designed for each individual pump model. They ensure the perfect interaction of all materials for smooth running properties, high uptime and maximum efficiency.

Best performance

Busch genuine vacuum pump vanes are extremely resistant to wear and humidity. We have tried and tested our vanes under the harshest conditions. In thousands of applications throughout the world, they deliver reliable, stable performance day after day.

No risks from counterfeits

Counterfeit parts are designed to look like Busch genuine vacuum pump vanes. However, they do not meet the high Busch standards for quality or performance. Only Busch genuine vacuum pump vanes will give you peace of mind and the best price-performance ratio.

Sign of quality

They contribute directly to high efficiency, reliability and performance. Therefore, only highly resilient vanes should be used.

Busch genuine vacuum pump vanes are all subject to individual quality assurance checks during production. Each has its own signature of origin, with an individual batch and tracking number, which makes it fully traceable. This engraving cannot be scratched off and gives you the security of using only genuine Busch parts.

Your HUCKEPACK pump is equipped with vanes made of either oil-sintered glass fiber (Phisa-T), resin-impregnated carbon (Titan), or extruded carbon composite (Xenon). The material is chosen depending on the needs of your application.

Our R5 pumps are equipped with either carbon composite (Selen) or glass fiber (EGS T-23) vanes.

Depending on the size of your ZEBRA vacuum pump, it is equipped with carbon, resin or phenol-formaldehyde (PF) resin vane.

-

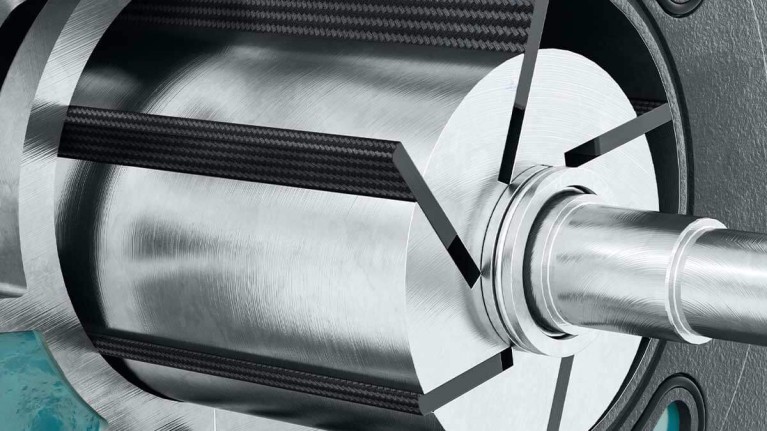

Busch genuine carbon fiber composite vane

-

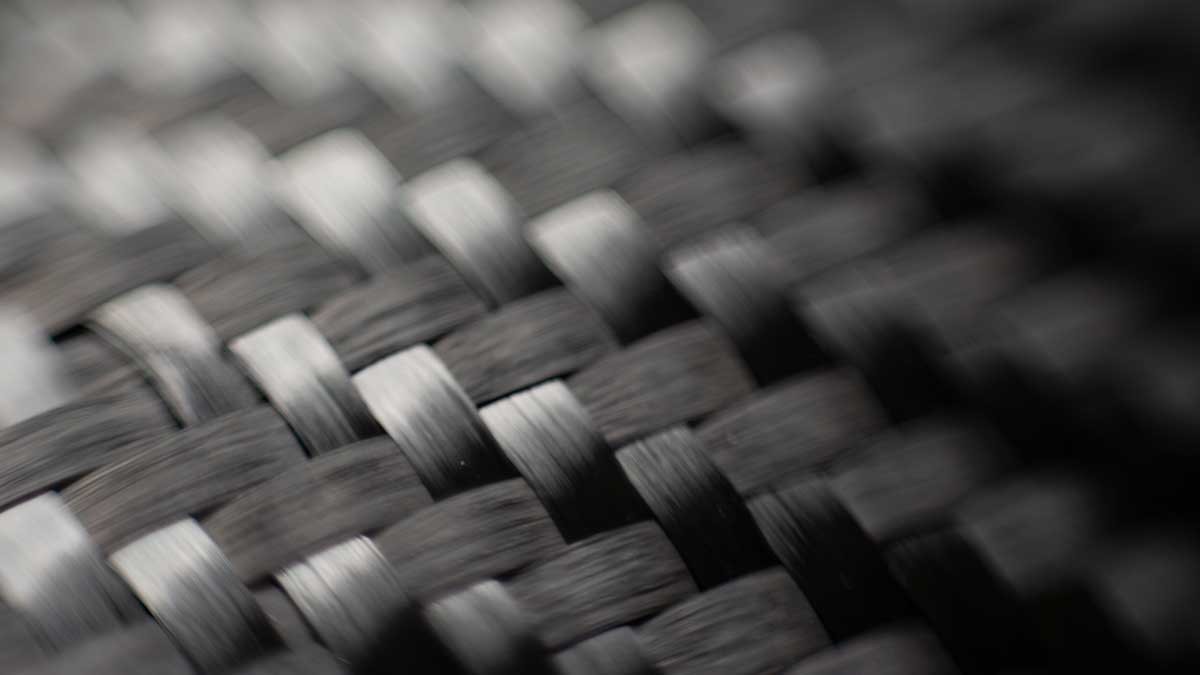

Detail view of a carbon fiber vane

GRAPHITE VANES

Busch genuine graphite vanes for dry-running rotary vane vacuum pumps such as SECO.Depending on the model of your SECO vacuum pump, its graphite vanes are made of either heavy-duty graphite (SIGRAFINE EK 60), salt-impregnated electrographite (FE-679PS), or carbon fiber (Aerodur 274 Zirkon).

-

Busch genuine graphite vane

-

Detail view of a graphite vane

R5 VANES

The vanes of R5 vacuum pumps have to be replaced by a Busch service technician.To replace the vanes of your R5, several parts need to be dismantled from your vacuum pump, including the cylinder and rotor inside the compression chamber. Upon reinsertion, the parts must be placed back with absolute accuracy. Incorrect placement of the rotor can severely affect your vacuum pump’s function and could lead to faulty pressure levels or a complete breakdown.

Our skilled service experts are happy to replace the vanes for you on-site.

Please contact your local Busch representative.

Compatible Busch vacuum pumps | Article number | Basic material |

|---|---|---|

R5 RB 0006 C, R5 RB 0006 E | 0722000248 | EGS T-23 |

R5 RA 0010 C, R5 RB 0021 C, R5 RC 0021 C | 0722515895 | EGS T-23 |

R5 RA 0016 C | 0722139665 | EGS T-23 |

R5 RA 0025 F | 0722000270 | EGS T-23 |

R5 RA 0040 F | 0722000300 | EGS T-23 |

R5 RA 0063 F | 0722000330 | EGS T-23 |

R5 RA 0100 F | 0722000360 | EGS T-23 |

R5 RA 0155 A | 0722561959 | Plastic |

R5 RA 0165 D, R5 RA 0205 D | 0722516573 | Aerodur Selen |

R5 RA 0255 D, R5 RA 0305 D | 0722516729 | Aerodur Selen |

R5 RA 0400 C, R5 RA 0502 C | 0722000454 | Aerodur Selen |

R5 RA 0630 C, R5 RA 0840 A PLUS | 0722000455 | Aerodur Selen |

R5 RA 1000 B, R5 RA 1000 A PLUS | 0722000456 | Aerodur Selen |

R5 RA 1600 B, R5 RA 1600 A PLUS | 0722000457 | Aerodur Selen |

R5 PB 0003 D, R5 PB 0004 C | 0722136478 | Ryton R-7 |

R5 PB 0008 C | 0722116551 | EGS T-23 |

R5 KB 0010 E, R5 KB 0016 E | 0724105206 | EGS T-23 |

R5 KB 0020 D, R5 KB 0025 F | 0724118546 | EGS T-23 |

R5 KB 0040 D | 0724118303 | EGS T-23 |

R5 RE 0040 B, R5 RE 0063 B | 0722119056 | EGS T-23 |

R5 RD 0200 A, R5 RD 0240 A | 0722211380 | Aerodur Selen |

R5 RD 0300 A, R5 RD 0360 A | 0722211381 | Aerodur Selen |

R5 RU 0050 B | 0722207561 | EGS T-23 |

R5 RU 0070 B | 0722206152 | EGS T-23 |

R5 KD 0012 A, R5 KD 0020 A | 0722201522 | Ryton R-7 |

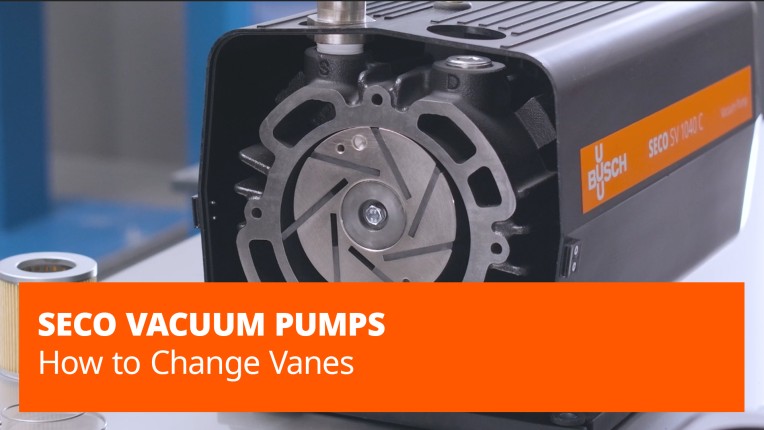

Seco vanes

The vanes of all other SECO models have to be replaced by a Busch service technician.

The replacement process requires that several parts are disassembled, including the cylinder and rotor inside the compression chamber. These parts have to be reinserted with absolute accuracy, as incorrect placement can lead to faulty pressure levels or a complete breakdown.

Our skilled service experts are happy to replace the vanes for you on-site. Please contact your local Busch representative.

Compatible Busch vacuum pumps | Article number | Basic material |

|---|---|---|

SECO SV 1003 D | 0722104640 | EK 60 |

SECO SV 1005 D | 0722141943 | EK 60 |

SECO SV 1008 C, SECO SD 1008 C | 0722133118 | FE679PS |

SECO SV 1010 C, SECO SD 1010 C | 0722554297 | Aerodur Zirkon |

SECO SV 1016 C, SECO SD 1016 C | 722554298 | Aerodur Zirkon |

SECO SV 1025 C, SECO SD 1025 C, SECO DC 0025 C | 0722554302 | Aerodur Zirkon |

SECO SV 1025 C | 0722533536 | EK 60 |

SECO SV 1040 C, SECO SV 1040 C, SECO DC 0040 C | 0722207620 | Aerodur Zirkon |

SECO SV 1040 C | 0722534079 | EK 60 |

SECO SV 1063 B, SECO SD 1063 B, SECO DC 0063 B | 0722000016 | EK 60 |

SECO SV 1080 B, SECO SD 1080 B, SECO DC 0080 B | 0722000017 | EK 60 |

SECO SV 1100 C , SECO SD 1100 C, SECO DC 0100 C | 0722500122 | EK 60 |

SECO SG 0008 A | 0722162513 | Aerodur Zirkon |

HUCKEPACK VANES

The vanes of HUCKEPACK vacuum pumps have to be replaced by a Busch service technician.To replace the vanes of your HUCKEPACK, several parts need to be dismantled from your vacuum pump. HUCKEPACK are two-stage vacuum pumps that have two compression chambers and two rotors. Both chambers and rotors must be reassembled with absolute accuracy. Incorrect placement can severely affect your vacuum pump’s function and could lead to faulty pressure levels or a complete breakdown.

Our skilled service experts are happy to replace vanes for you on-site.

Please contact your local Busch representative.

Compatible Busch vacuum pumps | Article number | Basic material |

|---|---|---|

HUCKEPACK HO 0429 F | 0722510545 | Titan |

HUCKEPACK HO 0429 F | 0722510545 | Titan |

HUCKEPACK HO 0433 F | 0722530782 | PHISA T. |

HUCKEPACK HO 0433 F | 0722530783 | PHISA T. |

HUCKEPACK HO 0437 F, HUCKEPACK HO 0441 F | 0722530788 | PHISA T. |

HUCKEPACK HO 0437 F | 0722530788 | PHISA T. |

HUCKEPACK HO 0441 F | 0722530787 | PHISA T. |

ZEBRA VANES

The vanes for ZEBRA vacuum pumps can only be purchased as part of a service kit. For more information, please contact our service experts.Operation and Restoration services

FAQ

What is the role of a vane in a vacuum pump/compressor?

Vanes are indispensable for the vacuum generation in a dry-running or oil-lubricated rotary vane vacuum pump. In a cylindrical housing, a rotor with several vanes is mounted eccentrically. Due to centrifugal force, these vanes slide out and form chambers between themselves and the housing. The pumped medium is trapped inside these chambers. During further rotation, their volume is constantly reduced. Thereby, the pumped medium is compressed and transported to the outlet.

Can I use generic vanes in my Busch vacuum pump/compressor?

Busch genuine vacuum pump vanes ensure optimum performance and long lifetime of your vacuum pump. Third-party replacement vanes may not. Their use also implies the expiry of any warranty claims.

Is it safe to use generic vanes in my Busch vacuum pump/compressor?

Only Busch genuine spare parts like vanes, filters, etc. ensure the optimum performance of your Busch vacuum pump. Third-party parts have not been tested according to our high Busch standards and we cannot guarantee their safety.

How can I identify Busch genuine vacuum pump vanes?

Every Busch genuine vacuum pump vane has its own signature of origin, with an individual batch and tracking number, which makes it fully traceable. This engraving cannot be scratched off.

Can I use one type of vane for all Busch vacuum pumps?

Vanes are specific to each type of dry-running or oil-lubricated vacuum pump. Furthermore, dimensions and number of vanes differ from vacuum pump to vacuum pump.

Which vane can I use for my Busch vacuum pump?

Please consult our Parts Finder or search for your Busch vacuum pump vane in the article list on this page.

Can I use Busch genuine vacuum pump vanes in third-party vacuum pumps?

No. We only test our genuine spare parts for our vacuum pumps. Busch vanes, filters, etc. will not support other technologies.

Does the application also play a role in vane choice or just the vacuum pump model?

In some cases, the application can influence the choice of vane. Please check with your local Busch expert.

What happens if I do not regularly replace the vanes in my rotary vane vacuum pump/compressor?

Overall performance will be affected. There is also a possibility of increase in operational noise and the risk of pump breakdown.

How often do I have to replace the vanes in my rotary vane vacuum pump/compressor?

This very much depends on the application. Time frames do vary. For some applications with solid by-products, it is more likely that you will need a replacement vane more often. Please refer to the instruction manual for your specific product.

How do I replace the vanes in my rotary vane vacuum pump/compressor?

You can find instructions on how to replace the vanes of your rotary vane vacuum pump or compressor in the respective instruction manual. Busch genuine service kits provide all necessary parts, including vanes, seals, gaskets, etc.

Please be aware that R5, HUCKEPACK, and some SECO vanes have to be replaced by a Busch service technician.

To replace the vanes of your R5, HUCKEPACK, or SECO, several parts must be dismantled, including the compression chamber. Upon reinsertion, these parts must be placed back with absolute accuracy. Incorrect placement can severely affect your vacuum pump or compressor's function and could lead to faulty pressure levels or a complete breakdown.

Our skilled service experts are happy to replace the vanes for you on-site.

Please contact your local Busch representative.

Where can I find ZEBRA vanes?

The vanes for ZEBRA vacuum pumps can only be purchased as part of a service kit. Please contact our service experts to purchase the correct service kit or organize a vane replacement.