A power generator of the future

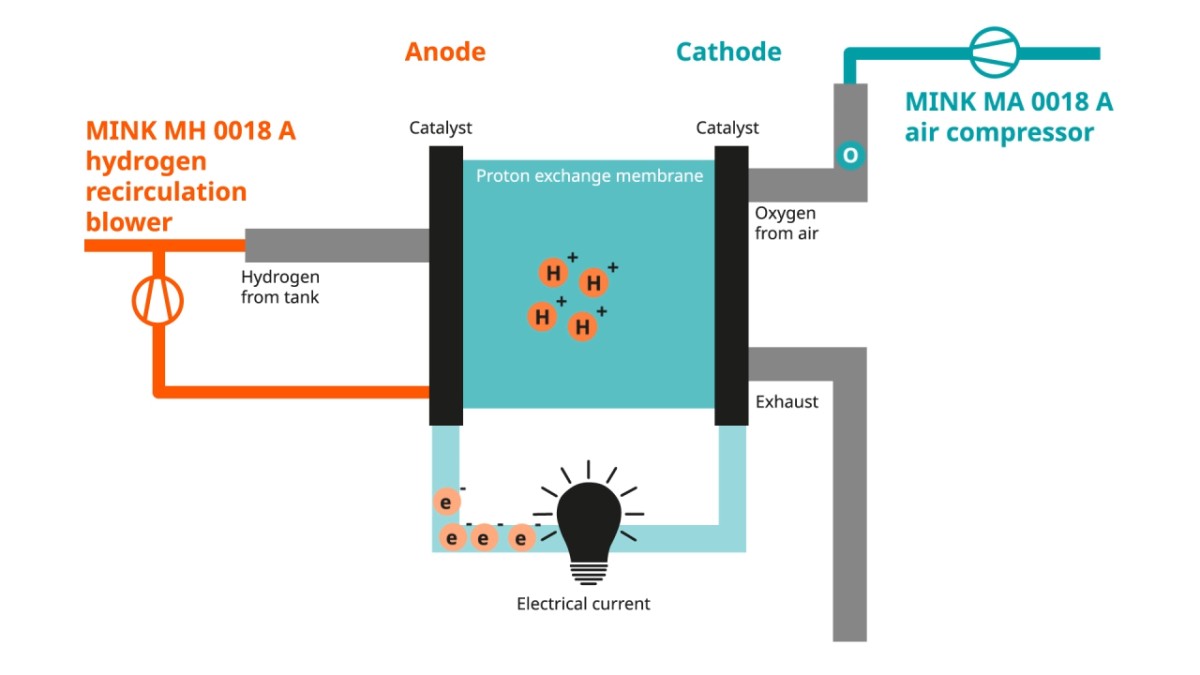

With the world focusing more than ever on reducing greenhouse gas emissions, the search is on for alternatives to conventional power generation. Ideally, these are not only cleaner but also more efficient. One sustainable energy generator that meets these requirements is increasingly gaining importance: the fuel cell.As fuel cells become more efficient and less expensive, they are emerging as a leading technology for producing clean electric power. Fuel cells generate electric current through an electrochemical process, which means they don’t burn fuel like traditional combustion engines. As a result, they don’t produce harmful emissions like greenhouse gasses or air pollutants.

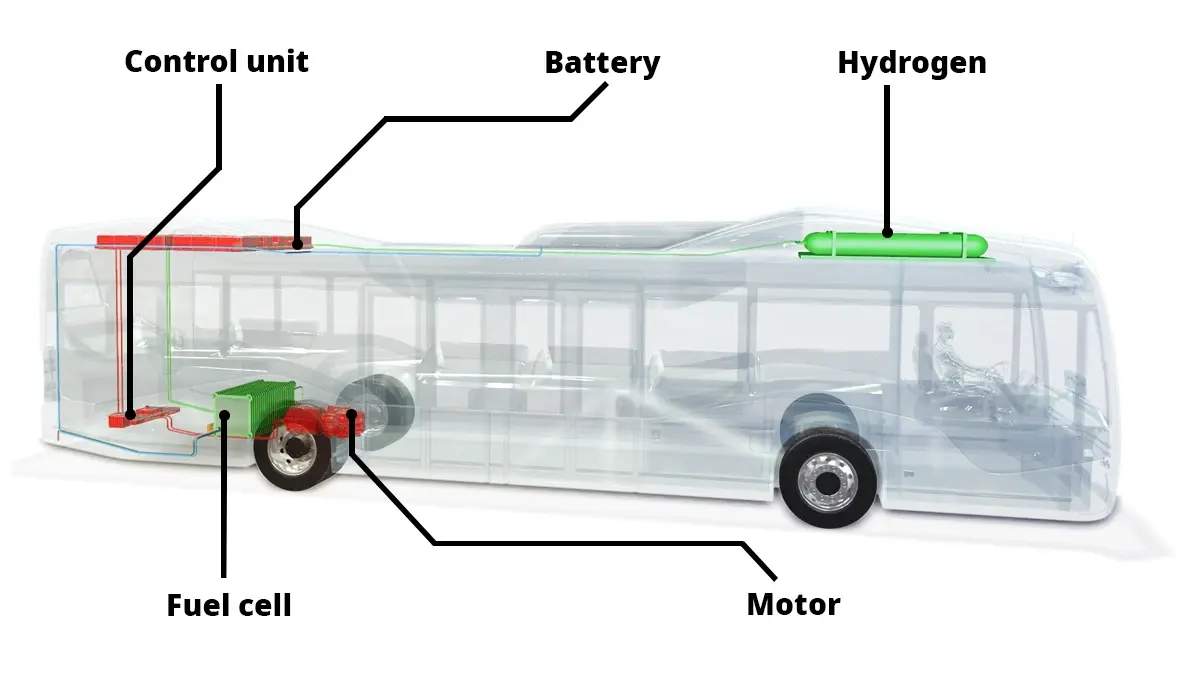

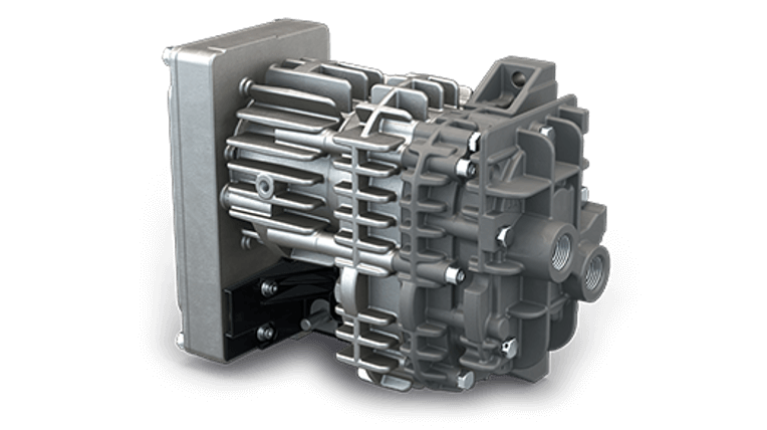

Busch Vacuum Solutions has made a decisive contribution to the efficient use of this sustainable technology by launching the first TÜV-certified hydrogen recirculation blower: the MINK MH 0018 A series. It has been specially developed for the reliable recirculation of hydrogen in fuel cells.