Tightness you can't see – reliability you can feel. Discover how innovative vacuum-based leak detection methods ensure climate-neutral gas-insulated systems remain safe, reliable, and sustainable.

It’s the hidden leaks that matter most. Especially when the future of energy depends on the integrity of systems designed to operate without emissions. As the energy sector moves away from harmful gases like SF₆ and toward cleaner alternatives, one question becomes critical: How can we ensure these systems stay reliably sealed?

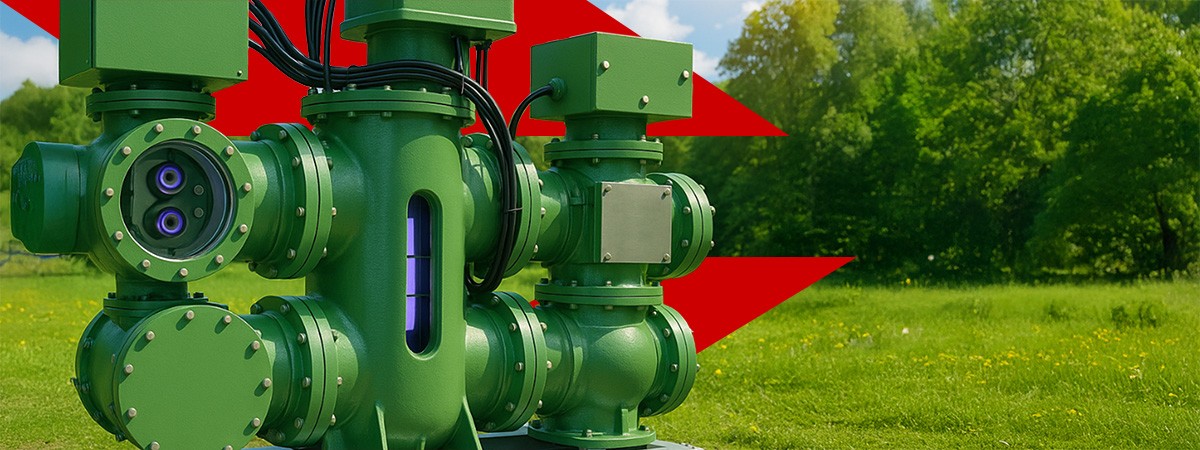

Replacing SF₆ – a new challenge for leak testing

For decades, sulfur hexafluoride (SF₆) was the industry standard for insulating high-voltage systems. While its dielectric strength is excellent, its environmental impact is equally significant. SF₆ has a global warming potential more than 24,000 times greater than CO₂. Today, the push toward decarbonization demands a new approach.

Modern insulation gases offer a safe, sustainable alternative to SF₆ – without its environmental drawbacks. But switching insulation gases introduces new technical challenges. Traditional leak detection methods, such as sniffing with tracer gases, don’t work effectively, especially when the gas used is difficult to distinguish from ambient air.

A vacuum-based solution

To meet this challenge, engineers have adopted a method that turns the usual approach on its head: Instead of measuring gas escaping from the inside, they measure gas entering from the outside. By creating a vacuum inside the sealed equipment and applying a small amount of tracer gas externally, even the tiniest leaks can be detected quickly and reliably.

This “outside-in” leak detection method eliminates the need for extensive tracer gas filling, sheaths, or manual intervention. It’s efficient, accurate, and scalable – exactly what’s needed for large high-voltage systems operating with environmentally friendly insulation gases.

Additionally, vacuum-based testing reduces environmental impact by minimizing tracer gas usage and improving detection speed, which streamlines maintenance and reduces downtime.

Sustainable technology requires smart testing

The vacuum method doesn’t just enhance accuracy – it also saves time, energy, and resources. Leak detection becomes faster, more consistent, and more sustainable. Combined with robust helium detectors like the ASM 340, engineers can ensure long-term integrity without relying on high global warming potential (GWP) gases.

Invisible Yet Essential

How leak detection supports the clean energy transition

Read more – sustainability meets system integrity

Switchgear used to rely on gases that linger in the atmosphere for thousands of years. Today, the goal is to make high-voltage technology climate-neutral – without sacrificing reliability. Leak detection with vacuum methods supports long-term system stability and enables a low-carbon future.

Switchgear used to rely on gases that linger in the atmosphere for thousands of years. Today, the goal is to make high-voltage technology climate-neutral – without sacrificing reliability. Leak detection with vacuum methods supports long-term system stability and enables a low-carbon future.