About Tvilum

Tvilum was founded in 1965 as a family business. After various mergers, it now belongs to the Danish investor group with Viking Trading ApS, Kristiansen Properties and CEO Torben Porsholdt. Today, Tvilum manufactures flat pack furniture in various styles and designs and sells them worldwide through various furniture retail chains. Tvilum's headquarters and main plant are in Faarvang, Denmark, with 450 employees. The remaining 700 employees work in two further production plants in Denmark and Poland.The process of automatic flat packaging

At the main plant in Faarvang, the furniture parts packed in flat packages are palletized by two robots and prepared for shipping in a fully automatic process. Using both robots (Fig. 1), the flat packages are held by vacuum via suction cups and stacked on pallets. In order to generate the necessary holding force, a dry-running rotary vane vacuum pump with a pumping speed of 140 cubic meters per hour was mounted on each of the two identical robots. However, they did not provide the required holding force, with the result that packages fell off several times a day, causing the system to come to a standstill and requiring manual intervention by the staff. This also often resulted in material damage.Peter Larsen, a maintenance technician, tried to make the automated handling process safer and added an additional rotary vane vacuum pump to each robot. These each had a pumping speed of 70 cubic meters per hour. As a result, the system became more reliable and the number of furniture packages that fell was reduced.

Another problem, however, was the noise of the rotary vane vacuum pumps. The vacuum pumps were positioned directly next to the robots and their noise level also affected nearby workstations. Peter Larsen tried to enclose the vacuum pumps, but this did not prove successful because the heat radiation from the vacuum pumps caused heat to build up inside the enclosure.

Peter Larsen then placed the vacuum pumps in a separate room and connected them to the robots via a pipeline. This solved the problem with noise and heat radiation in the packaging room, or at least moved it elsewhere. What remained was the elaborate and costly service work. Twice a year, the vacuum pumps were serviced, and the vanes had to be replaced.

The rotary vane vacuum pumps used were what are known as dry-running pumps. With this type of vacuum pump, the rotating vanes in the pump casing are subject to high levels of wear because they grind directly along the inside wall of the casing. The vanes containing graphite have a certain self-lubricating capacity, which slows down the wear somewhat, but cannot prevent it. As these vanes wear, there is also a loss of performance in terms of pumping speed and vacuum performance.

Busch vacuum system solution and its benefits

Contact with Busch Vacuum Solutions was established at a trade show where Busch presented a MINK claw vacuum pump that was adjustable via a frequency converter. As a result, Peter Larsen took a closer look at this type of vacuum technology. He believed it had the following advantages:MINK vacuum pumps compress the air completely contact-free. This means that the moving parts inside the vacuum pump do not come in contact with each other.

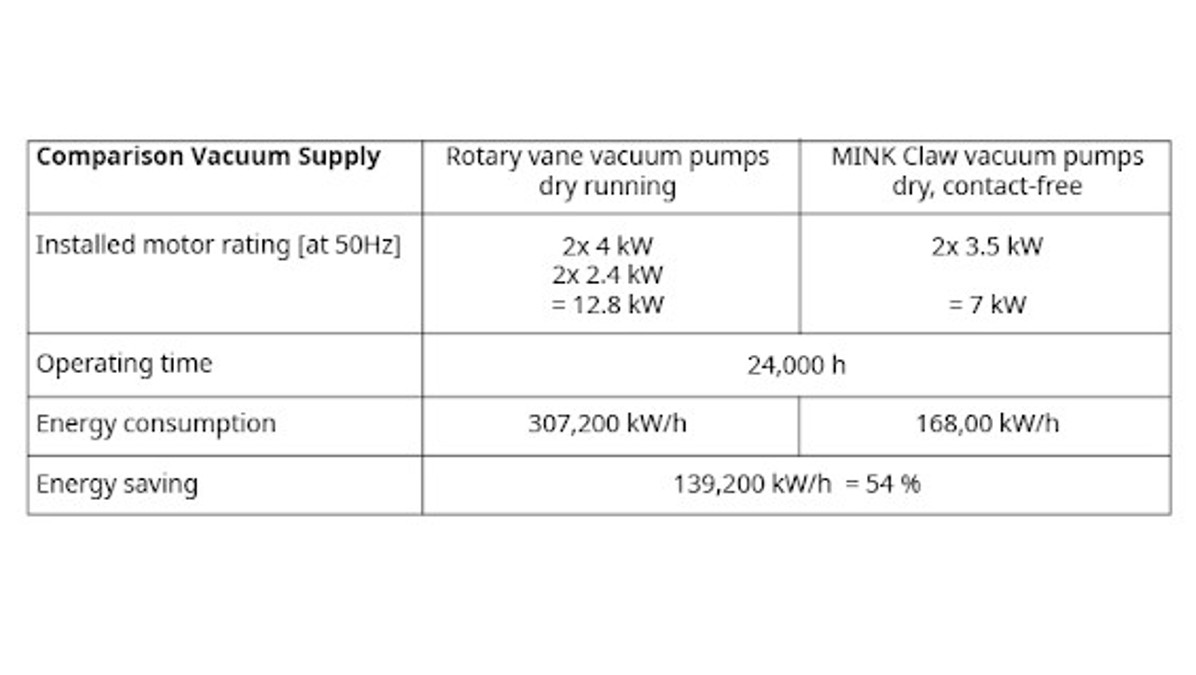

Peter Larsen was convinced by MINK claw vacuum technology and was given advice by vacuum experts from Busch Vacuum Solution. They recommended a vacuum system consisting of two MINK claw vacuum pumps (Fig. 2), each with a pumping speed of 140 cubic meters per hour and connected in parallel with a demand-driven control system. They were installed in a separate room in January 2019 and connected to the two robots via a pipeline.

Immediately after starting to use them, it became apparent to Peter Larsen that MINK claw vacuum pumps run much more quietly than dry-running rotary vane vacuum pumps. After one and a half years in operation, he can also state with reassurance that not a single package fell to the ground during this period due to insufficient holding force. In addition, the maintenance effort is minimal compared to the rotary vane vacuum pumps. The gear oil is only changed once a year just as a precaution. Since MINK claw vacuum pumps have no wearing parts, the costs for their replacement or purchase are completely eliminated.