ArxOnt - iStock.com.

Energy-Efficient Packaging of Pizza Toppings

Danish Crown Toppings

About Danish Crown Toppings

DK-Foods A/S, which was founded in 2003, became Danish Crown Toppings in 2017. Danish Crown Toppings is part of the Danish Crown Food division of the Danish Crown Group. Various types of pepperoni are produced, which are used as slices, cubes or sticks exclusively as toppings for pizzas. They are therefore pure B2B products supplied to manufacturers of frozen pizzas and fast food chains worldwide.Production takes place at the Danish site in Kjellerup with 110 employees in two-shift operation. The products are packed on a total of seven packaging lines with tray sealers or thermoforming machines in packaging sizes from one to 15 kilograms. All packaging machines were equipped with R5 rotary vane vacuum pumps from Busch as standard, while a second R5 rotary vane vacuum pump was added to the thermoforming machines in order to form the bottom film. At the beginning of 2017, Technical Manager Birger Brødløs had already started to think about how he could make the vacuum supply of the then five packaging machines more efficient.

His aim was to prevent heat radiating from the vacuum pumps into the production rooms. At that time, nine vacuum pumps were operated for 16 hours a day on five packaging lines with a total installed capacity of 28 kilowatts. The temperature in the production rooms is permanently kept at 14°C. The heat radiation from the vacuum pumps required an increased amount of energy from the air-conditioning system in order to prevent the temperature in the production rooms from rising.

Busch centralized vacuum solution

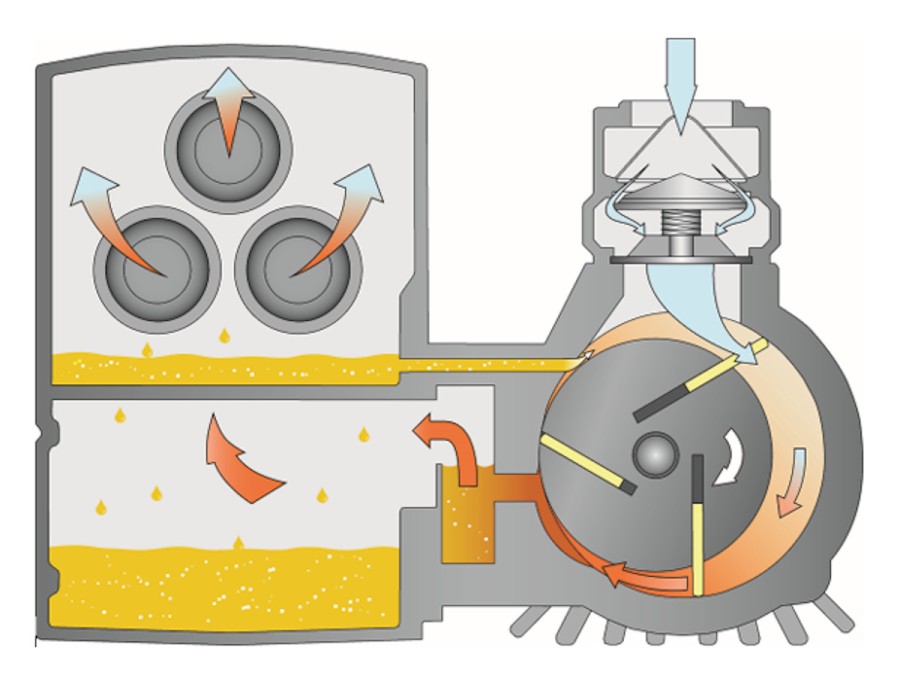

Birger Brødløs contacted the vacuum experts at Busch. They recommended he used a centralized vacuum supply that would be installed outside the production area. They said that this would completely eliminate noise and heat emissions in the production area. The project planning for the new centralized vacuum supply was carried out in such a way that the existing R5 vacuum pumps could be used in the new vacuum system and investment costs could thus be saved. The vacuum system was installed in a front building directly at the production building. In terms of technology, the vacuum system has a modular design and supplies the individual packaging machines with different vacuum levels via three ring lines.Four R5 rotary vane vacuum pumps (Fig. 1, Fig. 2) are connected to a vacuum vessel, which they permanently evacuate to 50 millibar. This "rough vacuum" prevails in the complete ring line up to the valve in the packaging machine. The vacuum vessel serves as a vacuum buffer. This ensures that sufficient pumping speed is maintained if, for example, all vacuum chambers require vacuum at the same time for extracting air. If 50 millibars are reached in the vacuum chambers, the process is switched over to the second ring line via valves. This ring line is connected to two additional R5 rotary vane vacuum pumps in the vacuum system, which generate a "medium vacuum" of 15 millibar.

-

Fig. 1: R5 rotary vane vacuum pump, as it was previously installed in the packaging machine and is now installed in the central vacuum supply system. Source: Busch Vacuum Solutions.

-

Fig. 2: Cutaway drawing of an oil-lubricated R5 rotary vane vacuum pump from Busch. These vacuum pumps achieve a very high vacuum level and are ideally suited for vacuum packaging. Source: Busch Vacuum Solutions.

-

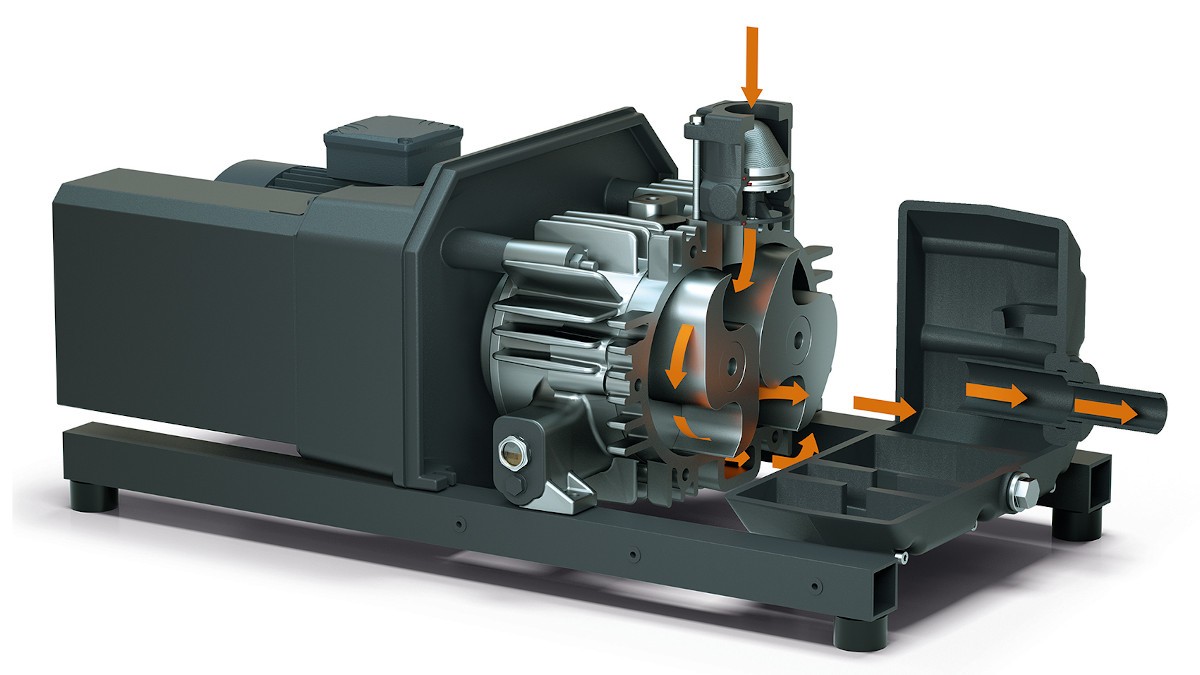

Fig. 3: MINK claw vacuum pumps achieve a maximum vacuum level of 60 millibar and are therefore used to thermoform the bottom film. Busch Vacuum Solutions.

-

Fig. 4: Cutaway drawing of a MINK claw vacuum pump: They operate without contact or operating materials, which makes them almost maintenance-free. Source: Busch Vacuum Solutions.

The vacuum system is controlled by a control system from Busch. It enables the adapting of the pumping speed directly to the actual demand from the packaging machines in operation. This means that individual vacuum pumps are switched on or off in line with actual demand. In daily practice, this means that the operating time of each individual vacuum pump is shorter and not, as was previously the case when the vacuum pumps were installed directly on or in the packaging machine, during two shifts. This facilitates further energy savings or results in power reserves. Birger Brødløs used this and in the meantime connected two more new packaging lines to the vacuum system, which was originally designed for five packaging lines.

After several years of operation, Birger Brødløs is confident that he made the right decision by centralizing the vacuum supply in order to pack the pepperoni for the global market extremely efficiently and reliably.