As the industrial world becomes ever more demanding, the world of vacuum must evolve to keep up. Each generation of vacuum pump is more efficient than the one it follows and comes equipped with new features that can bring something new to your process. However, not all features mean you need to purchase an entirely new vacuum system: There are also a number of upgrades available on the market for existing equipment. This article delves into the software and hardware upgrades you should consider to optimize your process.

Tune my Pump

Enhance efficiency with software and hardware upgrades

Software Upgrades: Higher Uptime and More Informed Decisions

New technology has brought many different ways of increasing efficiency. Arguably the most important development in recent years is the Internet of Things, or IoT for short. IoT refers to a network of devices – the “things” described in the name – that exchange data. The sensors in each device allow real-time information about their environment and process to be captured and shared between the devices in the net work. This allows for a more streamlined production process, monitoring in real time, and for trends to be identified.

An IoT solution can therefore be an excellent investment for your process. The benefits that this new software offers can be divided broadly into the following three categories.

1. Remote condition monitoring

One extremely practical advancement in IoT technology is the implementation of remote condition monitoring. This process allows operators to keep an eye on their vacuum pump’s performance, even when not right at its side. By collecting and analyzing equipment data, faults can be detected promptly, and equipment failure prevented.

2. Data analytics and reporting

The second benefit of IoT software is the data it collects on your vacuum pump. This can be analyzed and used to evaluate performance over a particular period. An analysis on this level can help you better understand how your equipment is performing. This allows you to make more informed decisions on matters that can influence your entire production process, such as whether to purchase additional new equipment, or to replace existing vacuum pumps.

3. Proactive maintenance

One of the most prominent benefits of remote condition monitoring is the shift from reactive to proactive maintenance. Traditional monitoring methods cannot identify errors as early, meaning that they are only discovered once they have taken hold – in the best case, during routine maintenance or, in the worst, as a result of a complete breakdown.

With remote condition monitoring, operators are informed as soon as the IoT system spots an anomaly, however small. An alert is sent by e-mail, SMS, or via an app, depending on the IoT solution, and the operator can intervene. This means that often the problem can be eliminated before it leads to total equipment failure.

The system will also give an alert when it is time for routine maintenance. This allows you both the freedom of not having to keep track of servicing intervals yourself, and the possibility to plan your servicing appointments around the requirements of your process.

An IoT solution can therefore be an excellent investment for your process. The benefits that this new software offers can be divided broadly into the following three categories.

1. Remote condition monitoring

One extremely practical advancement in IoT technology is the implementation of remote condition monitoring. This process allows operators to keep an eye on their vacuum pump’s performance, even when not right at its side. By collecting and analyzing equipment data, faults can be detected promptly, and equipment failure prevented.

2. Data analytics and reporting

The second benefit of IoT software is the data it collects on your vacuum pump. This can be analyzed and used to evaluate performance over a particular period. An analysis on this level can help you better understand how your equipment is performing. This allows you to make more informed decisions on matters that can influence your entire production process, such as whether to purchase additional new equipment, or to replace existing vacuum pumps.

3. Proactive maintenance

One of the most prominent benefits of remote condition monitoring is the shift from reactive to proactive maintenance. Traditional monitoring methods cannot identify errors as early, meaning that they are only discovered once they have taken hold – in the best case, during routine maintenance or, in the worst, as a result of a complete breakdown.

With remote condition monitoring, operators are informed as soon as the IoT system spots an anomaly, however small. An alert is sent by e-mail, SMS, or via an app, depending on the IoT solution, and the operator can intervene. This means that often the problem can be eliminated before it leads to total equipment failure.

The system will also give an alert when it is time for routine maintenance. This allows you both the freedom of not having to keep track of servicing intervals yourself, and the possibility to plan your servicing appointments around the requirements of your process.

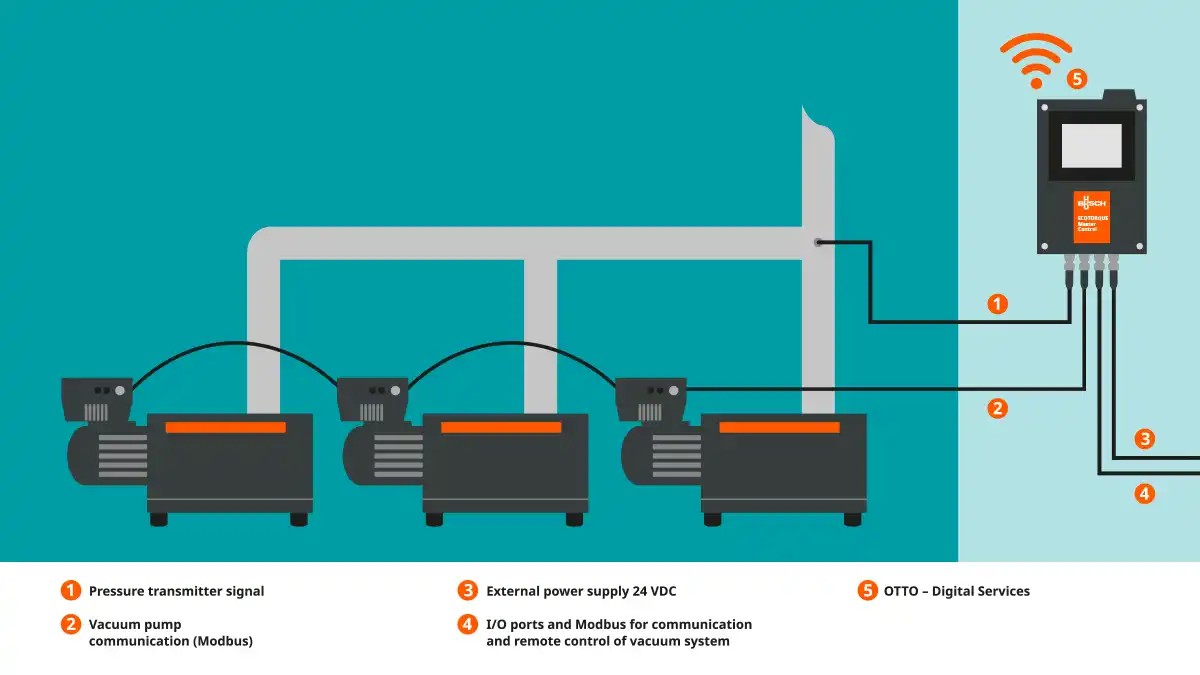

Installing an IoT Solution

To add IoT software to an existing pump, both software and a small amount of hardware is required. OO – Digital Services from Busch consists of an IoT Kit. This contains all the required sensors, and the IoT Box that comes preinstalled with the software and acts as a receptor. A Busch technician installs this onto your vacuum pump and tests the connectivity. Then the data flow can begin.

Hardware Upgrades: Greater Efficiency and Connectivity

It is not just software that has seen recent technological developments. Modern vacuum pumps also come equipped with new hardware that helps keep them at the cutting edge of efficiency and reliability. Although some are installed in new vacuum pumps straight from the factory, other options can be retrofitted. Here are some options that can open up new optimization possibilities for your process.

- Variable speed drive

Upgrading your vacuum pump with a variable speed drive (VSD) has one main benefit:

efficiency.

A traditional vacuum pump has no flexibility in its pumping speed. When it is on, it runs at full power, regardless of the process requirements. A VSD changes this. It adapts the pumping speed to only what is needed at that exact moment. This allows for significant energy savings, reducing operational costs and carbon footprint alike.

A VSD comes preinstalled in many new vacuum pumps but can also be retrofitted to existing equipment. Our VSD ECOTORQUE retrofit kit allows you to experience the benefits of a frequency-controlled vacuum pump without having to replace your existing technology.

- Teamwork with a Master Control

With a Master Control, you can take the efficiency of your vacuum pumps with VSD one step further. An ECOTORQUE Master Control is a quick and cost-effective solution to create a vacuum system. It allows you to connect up to eight vacuum pumps fitted with a VSD (integrated or retrofitted) and to control these as a group. The cascading function ensures that your process only has as many pumps online as is necessary at that moment. Each at the right pumping speed to meet the requirements of your process. In addition, the Master Control cycles the vacuum pumps it controls to ensure equal operating hours. And, should one have an outstanding alert, it will prioritize those that are running normally.

Unlike a central vacuum system, this is a very flexible solution. Vacuum pumps can be added and removed from the group as necessary, and they can be connected from their existing location.

- Heat recovery

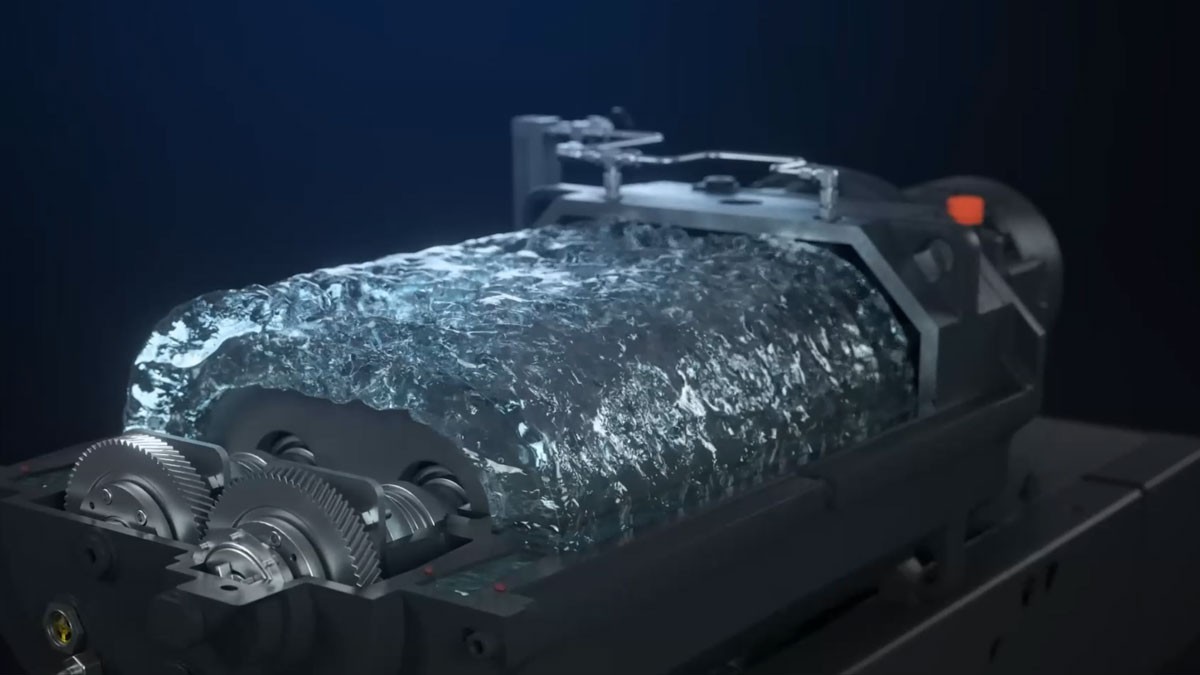

Another efficiency upgrade you could consider is changing your vacuum pump’s cooling system. While this does not affect the operation of the vacuum pump itself, it provides your production with other benefits.

As a vacuum pump works, it creates heat. In an air-cooled vacuum pump, this heat is emitted to the surrounding environment. This has two negatives: It heats the room where the vacuum pump is working, and the energy used to create this heat is lost. If the room has to be air conditioned as a result, this is a double energy-wasting effect. However, a water-cooled vacuum pump transfers the majority of the heat it produces to the cooling liquid. This hot water can then be reused elsewhere – somewhere in the production process where heat is required, to be circulated around the building for heating purposes, or to provide hot water for sanitary facilities.

Retrofit kits are available to change an air-cooled vacuum pump into a water-cooled vacuum pump.

Conclusion

If you are looking to upgrade your vacuum pump without investing in entirely new equipment, there are many different options available. From new software to retrofitted hardware, an upgrade isn’t just a new accessory – it’s a smart move. Bring your existing equipment up to date and benefit from the advantages these new investments can offer.

Contact us for more information.

We are happy to help you find the right upgrades to tune your vacuum pump.

We are happy to help you find the right upgrades to tune your vacuum pump.