Vacuum Packaging of Fresh Meat

Hygienically packaging fresh meat

Maulburg, Germany

|

14.07.2021

|

5 min

Using a vacuum or protective gas during the packaging process is one of today’s most common methods for hygienically packaging fresh meat, sausage goods and convenience products in portioned packaging with a long shelf life that is attractive to consumers.

Vacuum packaging has existed for over 50 years.

One of the pioneers of vacuum packaging is the Busch company, which developed the first vacuum pump specifically for this application in 1963.

One of the pioneers of vacuum packaging is the Busch company, which developed the first vacuum pump specifically for this application in 1963. Today,

Busch R5 rotary vane vacuum pumps are used worldwide in countless packaging machines. The intrinsic operating principle from the first machines in 1963 has remained; Busch has otherwise constantly further developed its vacuum pumps and adapted to new market requirements. But something else has also stayed the same: The vacuum pump is the heart of every packaging machine.

The quality of the vacuum pump to a large extent determines the quality of the packaging machine and, ultimately, the quality of the packaging.

The right selection of the vacuum pump definitively determine the quality of the packaging and thus the shelf life of the packaged goods.

The right selection and optimum design of the vacuum pump (fig. 2) definitively determine the quality of the packaging and thus the shelf life of the packaged goods and the preservation of its quality after the packaging process. In addition, selecting the right vacuum pump influences the reliability and economic efficiency of the packaging machine. To achieve the best possible results during vacuum packaging, the entire meat processing procedure must be considered. This is the only way that all process chain parameters can be taken into account, which can influence physical operations during the packaging process.

After slaughter, various biological processes take place in the meat. First, the meat becomes tough and dry, which can be indirectly attributed to the formation of lactic acid in the muscle fibres. As the process continues, the meat tissue is softened by enzymes that break down protein. This enables the meat to absorb moisture again, making it juicy and tender.

However, if this process takes too long, too much protein is broken down. This results in the development of ammonia and the meat becomes inedible. Meat maturation and spoilage are therefore processes that merge into one another.

By vacuum packaging meat quality is maintained for a longer period.

Vacuum packaging removes the oxygen from the meat. This

reduces the activity of bacteria that require oxygen and significantly increases shelf life. Removing the oxygen drastically slows the meat maturation process and the meat quality is maintained for a longer period.

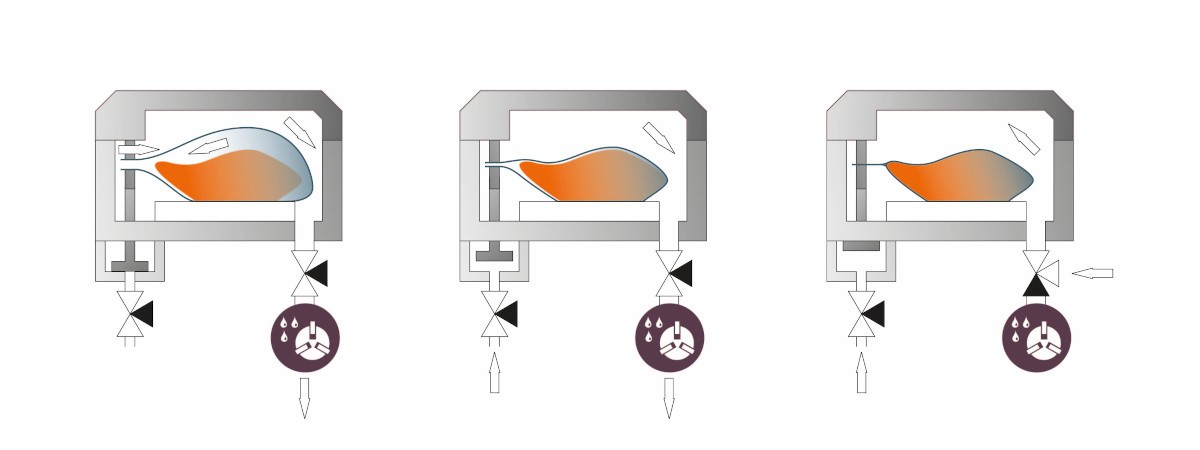

Physical processes during the meat packaging process

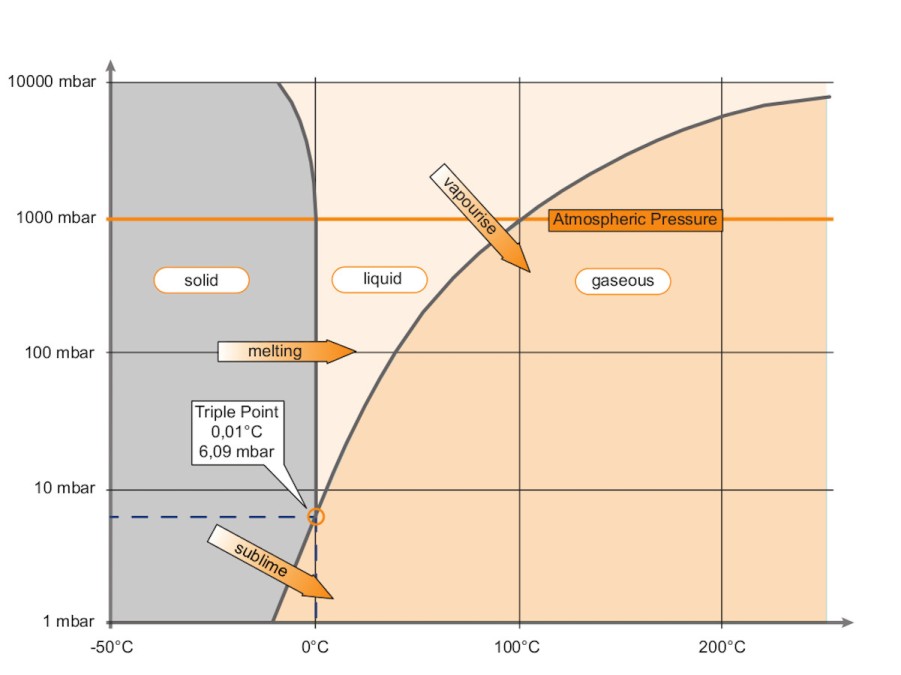

Removing the air from the packaging machine chamber (fig. 3) reduces the pressure and the oxygen content is reduced. At the same time, a pressure gradient is created from the inside of the meat to its surface. This can cause gas cavities in the meat to expand and gases can escape. If the meat is very moist, the water on its surface can evaporate once the pressure falls below vapour pressure and the amount of gas increases rapidly (fig. 4). The pressure in the packaging chamber now drops very slowly because the vacuum pump has to pump out the resulting additional water vapour.

Therefore, the amount of water on the surface of the meat that can evaporate and the temperature of the meat both have a considerable effect on the achievable pressure in the vacuum machine chamber. By ventilating the packaging chamber, the bag is pressed onto the surface of the meat and the remaining atmosphere in the bag is compressed. Depending on the product’s characteristics (gas pockets and water content), the pressure within the packaging bag can increase again after the packaging process because gas from the meat can escape. This means that the ultimate pressure with which the best packaging result is achieved depends on the condition of the meat.

Water vapour tolerance in meat packaging

An essential feature of a vacuum pump is the water vapour tolerance. This must be adjusted to the requirement. The following parameters influence the water vapour tolerance of a vacuum pump:

- Pressure range in which the vacuum pump is working

- Prevailing ambient and product temperatures

- Operating mode of the vacuum machine

- Installation conditions of the vacuum pump in the packaging machine

Pressure range

The pressure range depends on the performance of the vacuum pump and the packaging machine.

The higher the operating temperature of the vacuum pump, the higher its water vapour tolerance.

Modern rotary vane vacuum pumps from Busch (fig. 4) achieve ultimate pressures of 0.1 hPa (mbar). The chamber size and pumping speed of the vacuum pump determine the

evacuation time. In turn, the speed at which the triple point of water is achieved or at which the pressure falls below that point is dependent on both criteria. The triple point (also known as the three-phase point) is the point at which the three phases of water vapour, liquid water and ice occur at the same time. The triple point is at approx. 6 hPa (mbar).

Temperatures in meat packaging

In the ordinance on meat hygiene, the maximum ambient temperature is set at +12°C; the maximum product temperature is set at +7°C. In practice, these values vary. Both temperatures have an immediate influence on the operating temperature of the vacuum pump. As a rule of thumb: the higher the operating temperature of the vacuum pump, the higher its water vapour tolerance.

Installation and operating mode

The type of vacuum pump installation (installation room, ventilation, etc.) and the operating mode of the packaging machine (cycle operation, intermittent operation) also have a considerable influence on the operating temperature of the vacuum pump.

Ideal packaging in meat processing

To be able to achieve the best possible packaging results, interactions between the individual factors must be considered when designing the vacuum pump. A holistic approach to meat processing and cooperation between the vacuum pump manufacturer, the packaging machine manufacturer and the operator are the most important conditions for achieving the best quality.

With its large product portfolio specifically developed for vacuum packaging and decades of experience, Busch has developed unique expertise. With over 60 companies worldwide, Busch vacuum specialists are present across the globe when it comes to finding the suitable vacuum solution for vacuum packaging.

Maulburg, Germany

|

14.07.2021

|

5 min