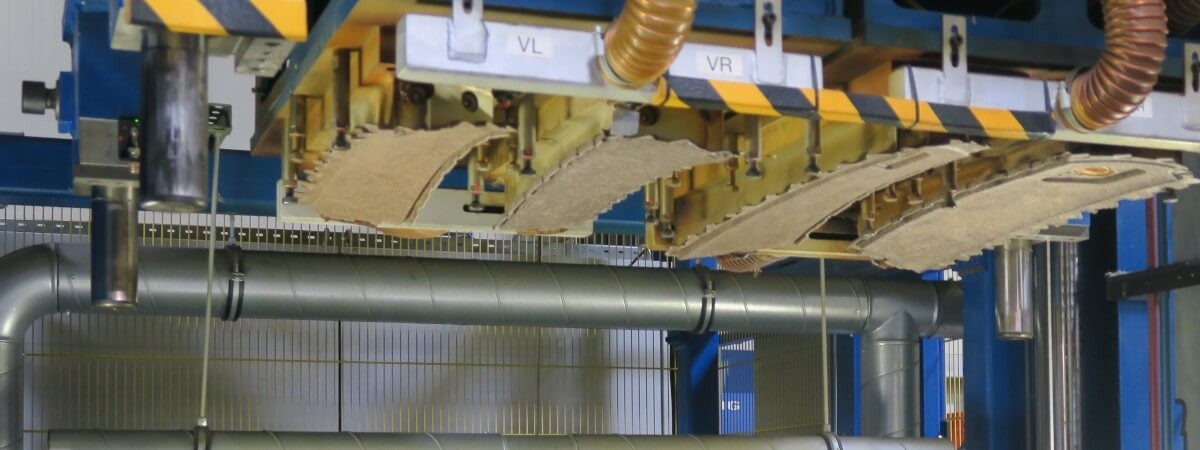

Fig. 1: Laminating system with four mould holders for the production of parts for interior door panels for the automotive industry. The moulded parts, made from natural polypropylene fibres, are secured in place by means of suction on the top, while the fabric coverings are positioned on the bottom, coated in a foam layer and adhesive. Source: Busch Vacuum Solutions.

High Economic Efficiency Thanks to the Right Choice of Vacuum Technology

Röchling Automotive

Choosing the right vacuum technology can lead to huge cost savings in many areas within plastics processing. Röchling Automotive Germany SE & Co. KG has undertaken a critical review of the existing vacuum supply used in its Wolfsburg plant to hold parts on laminating systems, and has collaborated with Dr.-Ing. K. Busch GmbH to find a new solution that will achieve savings amounting to well over ten times the cost of the investment.

Plastics processing in the automotive industry

Vacuum is used in many ways in plastics processing and treatment. It is often worthwhile for a company to take a close look at its processes and the vacuum technology. In many cases, both can be optimized in terms of economic efficiency and reliability.

It is often worthwhile for a company to take a close look at its processes and the vacuum technology. In many cases, both can be optimized in terms of economic efficiency and reliability.

This Röchling plant produces interior door panels for cars. Two laminating systems at the plant apply a decorative surface to supporting parts. To achieve this, the prefabricated supporting parts are placed from below in the holders of the laminating systems and secured in place using vacuum (Fig. 1). The covering, either fabric or imitation leather, is placed in the countermoulds. A layer of foam and adhesive has already been applied to the decorative moulds at this point. The parts are heated in the laminating systems and then pressed together for a few seconds so that the moulded part and the covering are bonded together using the adhesive. All parts that are covered in fabric or leather are produced in this manner on both laminating systems, before they are incorporated into the door panels.

In the past, ejectors were used to generate the needed vacuum. This method had two serious disadvantages:

1. In some cases, it was not possible to produce vacuum strong enough to hold the parts securely in place. The moulded parts made from natural fibres are, to varying degrees, permeable to air and not dimensionally stable. This means that they could not be correctly sucked into the mould holder because of the insufficiently strong vacuum, and therefore they were not level. As a result, leakage air from the ejectors was also sucked in, which further overloaded the ejectors. In practice, this means that slightly warped moulded parts could not be held in place and therefore could not be laminated. These parts had to be disposed of as waste.

2. The four ejectors respectively required an excessive amount of compressed air as an energy source, meaning that a reserve compressor had to be used, and the entire compressed air supply still broke down more than once. The compressed air consumption each day for two shifts was 1,280 cubic metres on average. Accounting for 230 production days per year and a cost of 16 euros per 1,000 cubic metres of compressed air, the compressed air costs associated with running the ejectors amounted to approximately 4,700 euros per year.

Vacuum system solution and its benefits for the customer

Before deciding to purchase an additional compressor, Karsten Pavenstädt contacted Dr.-Ing. K. Busch GmbH and arranged for a consultation with one of the company’s vacuum specialists. Together, they examined all the existing parameters and worked on a suitable solution. Busch recommended the use of a frequency-controlled MINK MV claw vacuum pump to supply both laminating systems with the required vacuum. Initially, Pavenstädt was sceptical as to whether this type of vacuum pump, running on a 2.1 kilowatt motor, would be capable of replacing a total of eight ejectors on each laminating system.Ultimately, a Simplex VO vacuum system (Fig. 2) was installed in early 2017. This system consists mainly of a MINK MV claw vacuum pump, which is mounted on a vacuum vessel. Thanks to the variable speed drive on this vacuum pump and a pressure switch on the vacuum vessel, the MINK MV is completely self-sufficient and keeps the vacuum level inside the vacuum vessel constant. The vacuum pump is positioned directly between both laminating systems and is connected with hoses to the four mould holders on each machine. Directly in front of the mould holders are valves in the hose connections, which open as soon as a moulded part is placed on the holder. The pumping speed of the MINK MV claw vacuum pump is so high that the moulded part is firmly sucked onto the holder and held securely in place. The intermediate vacuum vessel ensures that the required vacuum level is produced immediately, which accelerates the process to a considerable extent. Once the parts have been pressed together and bonded, the valves close once again and the laminated parts can be removed manually.

-

Fig. 2: Simplex VO 0080: A vacuum system with a frequency-controlled MINK MV claw vacuum pump and a vacuum vessel. Source: Busch Vacuum Solutions.

The calculated energy savings between the ejectors that ran on compressed air and the MINK claw vacuum pump are even higher in practice. This is because less pumping speed is required thanks to the quick securing of the parts and their perfect positioning in the mould holder. The system’s integrated, demand-driven control reduces the power immediately so that it uses just 20 percent of the full power on average. This results in annual energy costs of 200 euros, which equates to energy savings of 4,500 euros per year compared with the ejectors previously in use.

Waste has been reduced to virtually zero because all parts can be fixed securely in place, and the vacuum performance on both laminating machines is always at the precise vacuum level required, even when the parts to be secured are warped or very permeable to air.

The constant vacuum, which is always present, also allows for maximum savings. Employees can now place the parts to be laminated in the machine two at a time, and the parts are secured immediately. This increases the quantities produced.

Maintenance and repairs manager Karsten Pavenstädt is very happy with this solution, which he has implemented through collaboration with Dr.-Ing. K. Busch GmbH.

In addition to the cost savings, he now has a modern, safe vacuum supply, which is nearly maintenance-free and runs without operating fluids. The noise emissions caused by the ejectors directly at the laminating systems have also been eliminated. Since the MINK claw vacuum technology is considerably quieter than ejectors, the undesirable noise produced at the workstations has been reduced substantially. Furthermore, he does not need to invest in an additional compressor, since the plant’s compressed air supply is now sufficient again.

Waste has been reduced to virtually zero because all parts can be fixed securely in place, and the vacuum performance on both laminating machines is always at the precise vacuum level required, even when the parts to be secured are warped or very permeable to air.

The constant vacuum, which is always present, also allows for maximum savings. Employees can now place the parts to be laminated in the machine two at a time, and the parts are secured immediately. This increases the quantities produced.

Maintenance and repairs manager Karsten Pavenstädt is very happy with this solution, which he has implemented through collaboration with Dr.-Ing. K. Busch GmbH.

In addition to the cost savings, he now has a modern, safe vacuum supply, which is nearly maintenance-free and runs without operating fluids.