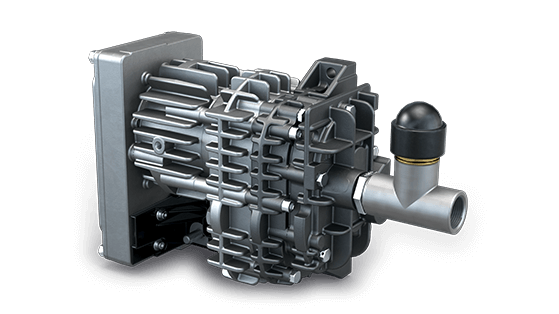

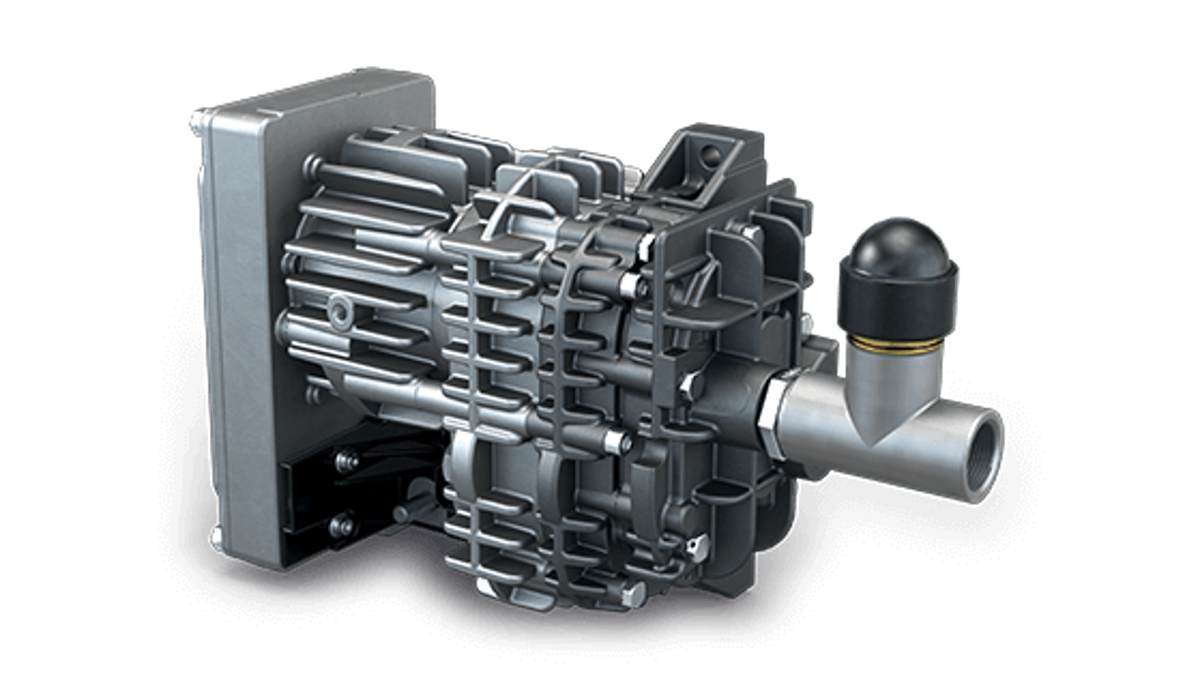

MINK MB 0018 A

Bomba de vacío de rotores de uña de funcionamiento en seco

También puede llamarnos directamente: +34 (0)93 861 61 60

Vacío para aplicaciones móviles en condiciones extremas

Robustas

Diseñada especialmente para aplicaciones móviles, puede utilizarse en condiciones extremas, en rangos de temperatura de entre -40 °C y +40 °C y en alturas de entre -1000 m y 4000 m, resistente a las vibraciones fuertes

Eficientes

La última tecnología de vacío de uña, compresión seca y sin contacto, sin contaminación del medio bombeado, accionamiento de velocidad variable inteligente, bajo consumo energético, ciclo de vida largo sin mantenimiento

Compacta

Pequeñas dimensiones gracias a su diseño «todo en uno»

Especificaciones técnicas

Mercados y aplicaciones

-

Recirculación de hidrógeno