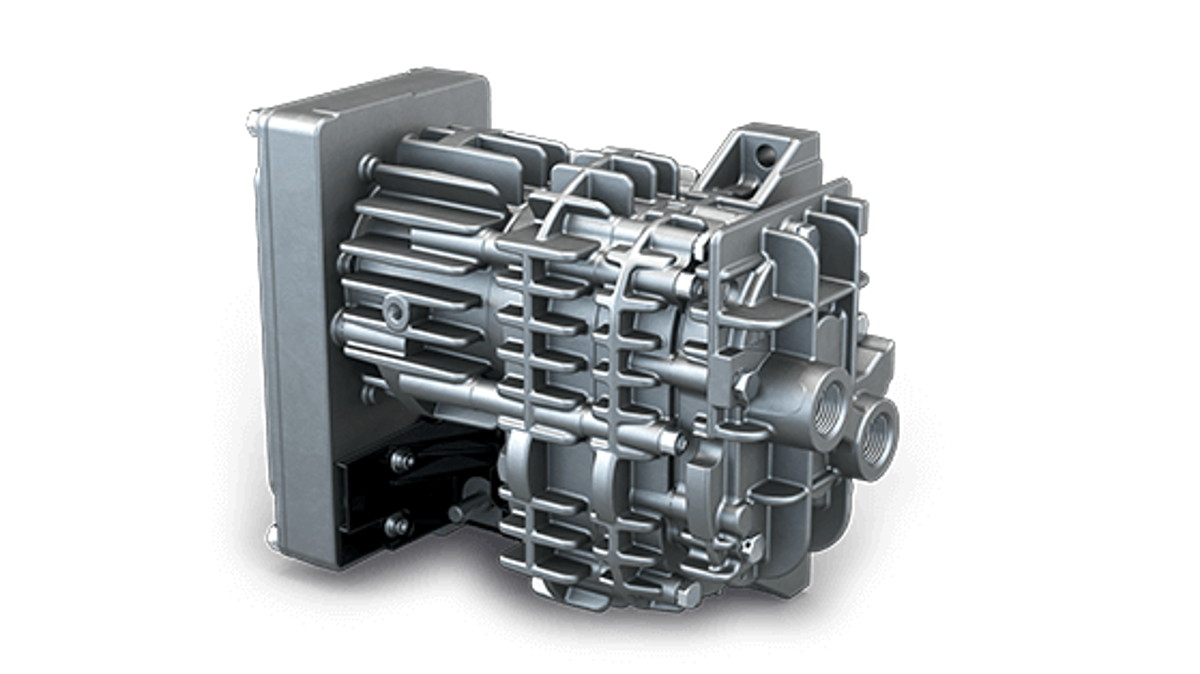

MINK MA 0018 A

Compresor de rotores de uña de funcionamiento en seco

También puede llamarnos directamente: +34 (0)93 861 61 60

Aire comprimido para aplicaciones móviles en condiciones extremas

Robusto

Diseñado especialmente para transportar aire en aplicaciones móviles, puede utilizarse en condiciones extremas, en rangos de temperatura de entre -40 °C y +100 °C y en alturas de entre -1,000 m y 4,000 m, resistente a las vibraciones fuertes

Eficiente

La última tecnología de compresores de rotores de uña, compresión seca y sin contacto, sin contaminación del medio bombeado, accionamiento de velocidad variable inteligente, bajo consumo energético, ciclo de vida largo sin mantenimiento

Compacto

Pequeñas dimensiones gracias a su diseño «todo en uno»

Especificaciones técnicas

Mercados y aplicaciones

-

Circulación

-

Recirculación de hidrógeno