Types of liquid ring vacuum pumps

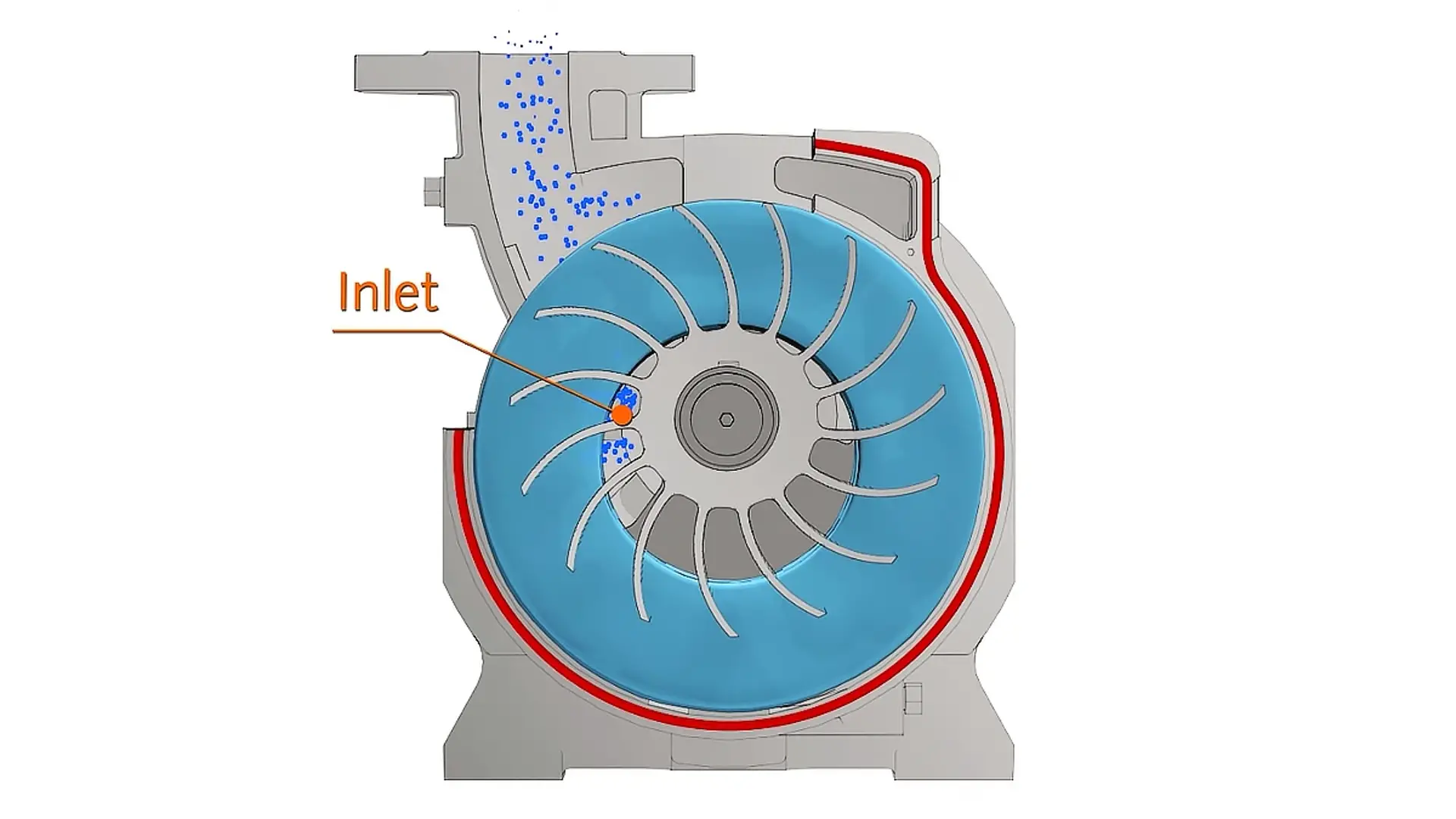

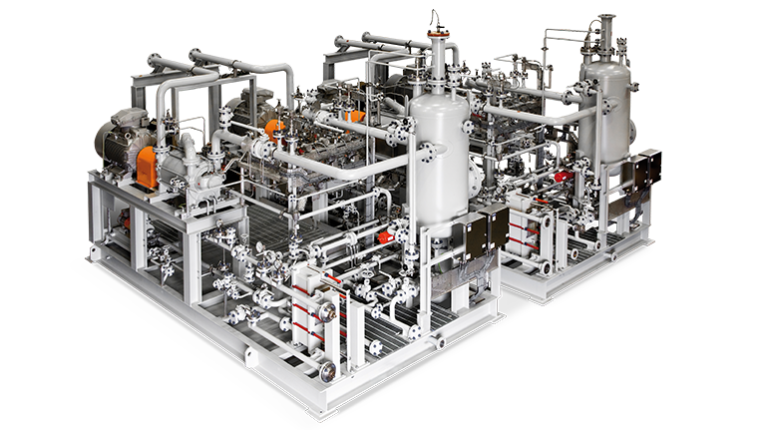

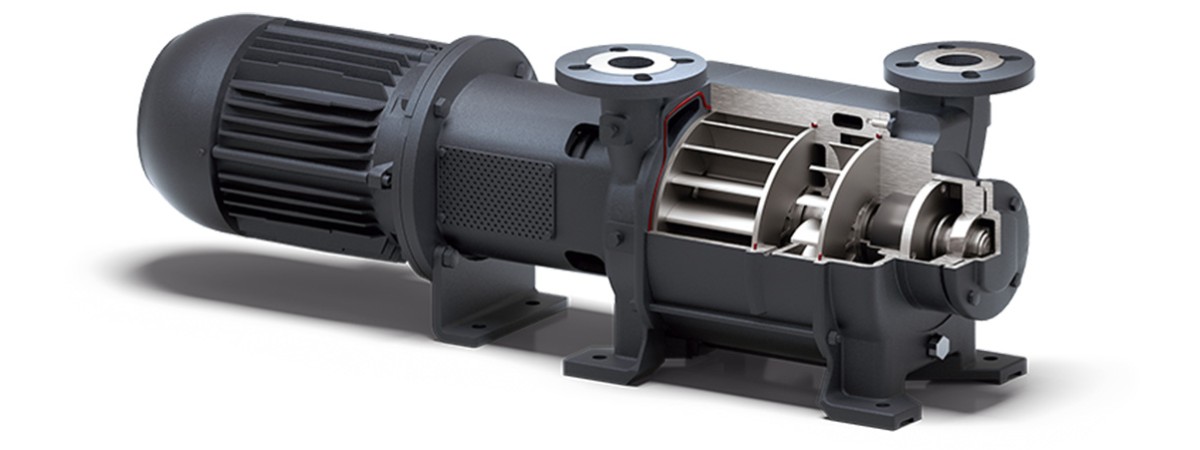

Liquid ring pumps are available in single- and two-stage versions. In single-stage versions, compression is carried out once. In two-stage versions, the pumped medium is compressed again to allow higher vacuum levels to be achieved. Operation as a compressor is also possible with some models of liquid ring vacuum pumps.Depending on the pumped medium, liquid ring vacuum pumps can be operated as a simple continuous flow system or as a partial or total recirculation system.

The operating fluid is usually water, but other liquids may be used if required to suit the process conditions.

Product series | Ultimate pressure / Overpressure | Version |

|---|---|---|

DOLPHIN LX | 33 hPa (mbar) | single-stage (valved) vacuum pump |

DOLPHIN LT | 33 hPa (mbar) | two-stage |

DOLPHIN VL | 33/130 hPa (mbar) | single- or two-stage |

DOLPHIN LM | 130 hPa (mbar) | single-stage |

DOLPHIN LR | 33 hPa (mbar) | single-stage (valved) |

DOLPHIN LB | 33 hPa (mbar) | two-stage vacuum pump / compressor |

DOLPHIN LA | 130 hPa (mbar) | single-stage |

DOLPHIN LG | 160 hPa (mbar) | single-stage (valved) |

DOLPHIN LN | 9 bar(g) | single- or two-stage compressor |