One of the five packaging lines for high-quality cheese specialities at the Crailsheim-Dinkelsbühl dairy. Photo: Crailsheim-Dinkelsbühl dairy.

Increased Productivity Thanks to Vacuum

Milchwerk Crailsheim-Dinkelsbühl eG

Balkan cheese, kashkaval and grilling cheese. The Crailsheim-Dinkelsbühl dairy processes 427,000 litres of raw milk every day to make these tasty cheese specialities. A vacuum system from Busch Vacuum Solutions now ensures faster cycle times and more stable manufacturing.

An endless band of white slides continuously through the production hall in Crailsheim, Baden-Württemberg. Three wells next to each other are being constantly filled with white cheese blocks by skilled hands. A colorful foil covers the packaging before it is evacuated, sealed and cut. While this was happening, a robot was assembling cardboard boxes, into which a vacuum gripper arm now carefully lifts the freshly packaged cheese. The cheese then goes to supermarkets and discounters all over Germany, both under big brand names or as the shop's own brand.

Quality Since 1927

The Crailsheim-Dinkelsbühl dairy plant was founded back in 1927. During the peak season from April to August, the cooperative's 232 employees work in three-shift operation. The rest of the year, they work in two shifts. Each year, they process 158 million litres of cow’s milk from 335 farms in the region into 21,300 tonnes of cheese. In different fat and cream levels, in brine, diced in oil, with herbs, chilli or olives, as semi-soft cheese, natural or smoked. They have been awarded nine gold and two silver prizes by the German Agricultural Society (DDLG).

Quality Since 1927

The Crailsheim-Dinkelsbühl dairy plant was founded back in 1927. During the peak season from April to August, the cooperative's 232 employees work in three-shift operation. The rest of the year, they work in two shifts. Each year, they process 158 million litres of cow’s milk from 335 farms in the region into 21,300 tonnes of cheese. In different fat and cream levels, in brine, diced in oil, with herbs, chilli or olives, as semi-soft cheese, natural or smoked. They have been awarded nine gold and two silver prizes by the German Agricultural Society (DDLG).

-

The Crailsheim-Dinkelsbühl dairy produces Balkan cheese, kashkaval cheese and grilling cheese from milk from regional farms. Photo: Crailsheim-Dinkelsbühl dairy.

The quality of the raw materials is particularly important at the dairy in Crailsheim-Dinkelsbühl. This also applies to committed and sustainable business relationships. The raw milk is collected every day by the cooperative’s own collection tankers from farms that operate without genetic engineering, according to environmental standards. The state-of-the-art in-house laboratory inspects and monitors all production processes. Production is also halal and kosher-certified.

Five packaging lines, one vacuum system

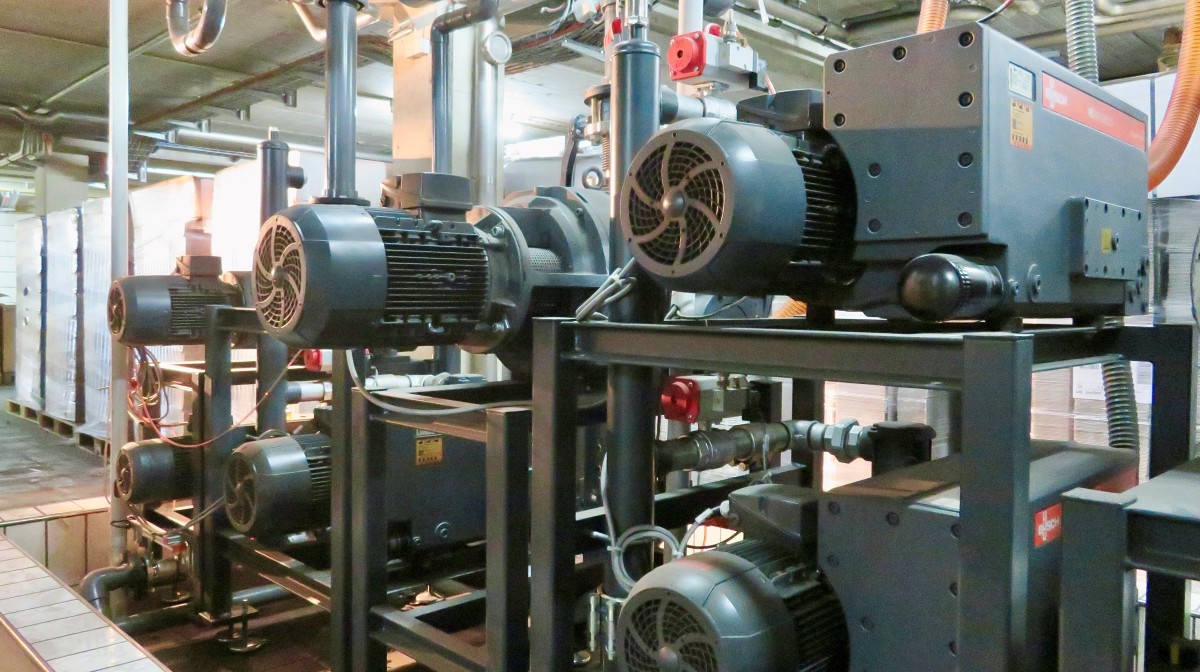

The five packaging lines are supplied with vacuum from a separate machine room. There, a pressure-controlled vacuum system from Busch, consisting of three R5 rotary vane vacuum pumps, three PANDA vacuum boosters, control cabinet and vacuum vessel, generates the required vacuum level – precisely adjusted to the moisture content of each type of cheese. This is used not only in thermoforming the various types of packaging, pump-down and sealing, but also to assemble the large shipping boxes and insert the packaged cheese.

The challenge in packaging cheese lies in the products' high humidity. This is why the Busch experts paid particular attention to sufficiently large filters and incorporated a moisture separator for the whey. The turnkey solution was installed on a weekend in 2021. On Monday, production continued immediately with the new system. Since then, the system has been running smoothly.

Five packaging lines, one vacuum system

The five packaging lines are supplied with vacuum from a separate machine room. There, a pressure-controlled vacuum system from Busch, consisting of three R5 rotary vane vacuum pumps, three PANDA vacuum boosters, control cabinet and vacuum vessel, generates the required vacuum level – precisely adjusted to the moisture content of each type of cheese. This is used not only in thermoforming the various types of packaging, pump-down and sealing, but also to assemble the large shipping boxes and insert the packaged cheese.

The challenge in packaging cheese lies in the products' high humidity. This is why the Busch experts paid particular attention to sufficiently large filters and incorporated a moisture separator for the whey. The turnkey solution was installed on a weekend in 2021. On Monday, production continued immediately with the new system. Since then, the system has been running smoothly.

-

A vacuum system from Busch Vacuum Solutions supplies the packaging lines with the required vacuum. Photo: Busch Vacuum Solutions.

Enormous Energy Savings

"In the past, we used Venturi nozzles for vacuum generation. Air consumption was extremely high. It was a total waste of energy. With the new vacuum system from Busch, we save 38,000 kWh per year," says Josef Vögele, Managing Director of Milchwerk Crailsheim-Dinkelsbühl enthusiastically, adding: "We have received 40% of the investment amount for the vacuum system back from the Federal Office for Economic Affairs and Export Control (BAFA). Busch compiled all the documents required for the funding application for us."

The old vacuum supply was not only less energy efficient, but it also had insufficient pumping speed for the desired increase in the number of cycles. Vögele is pleased: "With the new vacuum system from Busch, we can now run up to twelve cycles per minute instead of nine. The vacuum is applied much more quickly and leads to a significant increase in productivity – while at the same time reducing energy consumption."

"In the past, we used Venturi nozzles for vacuum generation. Air consumption was extremely high. It was a total waste of energy. With the new vacuum system from Busch, we save 38,000 kWh per year," says Josef Vögele, Managing Director of Milchwerk Crailsheim-Dinkelsbühl enthusiastically, adding: "We have received 40% of the investment amount for the vacuum system back from the Federal Office for Economic Affairs and Export Control (BAFA). Busch compiled all the documents required for the funding application for us."

The old vacuum supply was not only less energy efficient, but it also had insufficient pumping speed for the desired increase in the number of cycles. Vögele is pleased: "With the new vacuum system from Busch, we can now run up to twelve cycles per minute instead of nine. The vacuum is applied much more quickly and leads to a significant increase in productivity – while at the same time reducing energy consumption."

-

Vacuum is also used to assemble the cartons and carefully insert the packaged cheese. Photo: Busch Vacuum Solutions.

Markus Otterbach, Technical Manager in charge of maintaining the system, is also extremely pleased with the new vacuum system: "We package very moist products, some with spices. This also produces cheese crumbs. Nevertheless, the Busch vacuum system operates smoothly. We don't really have to worry about it. Add a little oil from time to time. Otherwise we don't do anything. Virtually no maintenance is required."