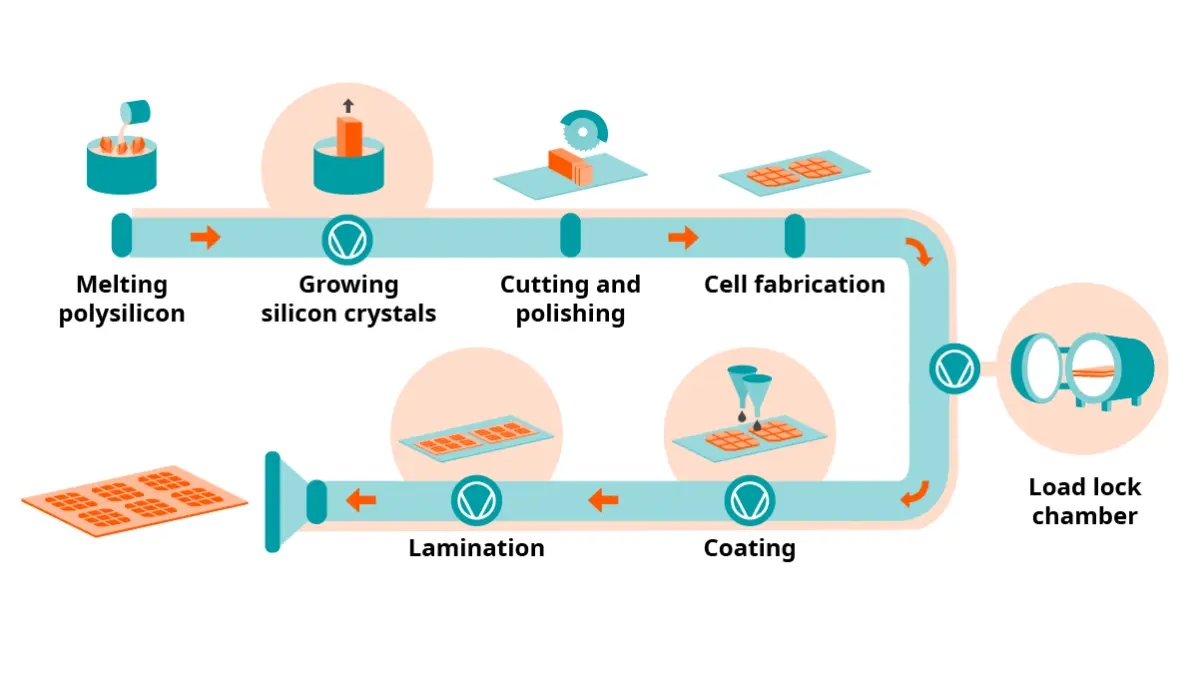

The role of vacuum in solar cell manufacturing

The solar industry is paving the way for renewable energy sources of the future. Vacuum plays a key role in future-proofing solar panel manufacturing. It is used from the first moment to create the silicon that makes up each cell, right up to laminating the final layers together.Solar panels are a popular choice for consumers and businesses as the technology becomes more efficient and cost-effective. However, as the demand for solar panels continues to grow, so does the need for more efficient production processes.

By utilizing cutting-edge vacuum technology, manufacturers can produce solar panels at a faster rate and increase the panels’ efficiency and durability.

Additionally, optimal vacuum technology can also help reduce waste and increase the sustainability of the solar panel production process. Less material is wasted by ensuring that coatings are distributed evenly onto the solar cells.

Busch offers optimal vacuum solutions for the solar power industry.