Vacuum packaging

The use of vacuum was one of the most groundbreaking developments in the packaging industry. Busch is a pioneer in this field.

What are you looking for?

Our oil-lubricated rotary vane vacuum pumps and dry screw vacuum pumps are perfectly matched to the needs of the food industry and are continuously being further developed together with our customers.

Process optimization of vacuum packaging

Our solutions are present in most chamber packaging machines, thermoforming packaging machines, tray sealing machines and bag filling machines throughout the world.

Find out which Busch solution can help you to optimize your packaging process:

Learn more about vacuum packaging

What is vacuum packaging?

Vacuum packaging is the technique of removing air from a package containing a product, usually food, before it is sealed. The air and thus the oxygen are extracted, and the product is preserved.

How does a vacuum packaging system work?

The product to be packaged is placed in a bag, on a tray or between two vacuum-tight foils. Inside a vacuum chamber or a sealing station, this package is then evacuated by means of a vacuum pump. After reaching the respective target vacuum, the package is sealed. For certain products, a specifically defined gas mixture is introduced into the packaging prior to sealing. This is called modified atmosphere packaging (MAP).

Where is vacuum used in the packaging process?

Vacuum frequently plays an essential role in packaging processes. In the production of packages, vacuum is, for example, used for thermoforming. Vacuum is also employed in tray sealing, chamber packaging, thermoforming and bag filling packaging machines and in many other packaging applications. Furthermore, vacuum is used for pick and place during the packaging process, as well as for handling of packages.

What are some examples for the use of Busch vacuum technology in packaging applications?

Busch Vacuum Solutions is the market leader in vacuum technology for food packaging and delivers more than 3 million R5 rotary vane vacuum pumps into the vacuum packaging market worldwide. Here are some case studies:

Learn more about vacuum packaging applications

How is vacuum packaging used in the food industry?

Vacuum packaging of fresh foodstuffs allows a reduction of oxygen in the package by around a factor of 200. This makes it possible to maintain the quality, appearance, freshness, and flavor of the packaged product. The growth of aerobic bacteria and thus oxidation and degradation of the product are prevented. This, in turn, helps to drastically reduce global food waste.

In addition, vacuum packaging allows for attractive product presentation for the customer, especially of convenience food, at the point of sale.

For certain products, a special gas mixture is introduced into the package before it is finally sealed. This technique is called modified atmosphere packaging (MAP).

How are foodstuffs vacuum packaged?

Vacuum helps to keep food fresh for a long time. With no loss in quality. Depending on the type of food to be packaged as well as the corresponding requirements, there are several possible processes. These include chamber packaging, thermoforming packaging, clipped packaging and carousel packaging.

Every vacuum packaging process starts with placing the products into some type of packaging. Either inside a bag, between an upper and a lower foil, or into a tray. The air, and thus the oxygen, is then evacuated from the packaging before it is sealed. This ensures an extended shelf life for the packaged product due to a reduced growth of oxygen-dependent bacteria. Furthermore, the taste, smell and appearance of the packaged products are preserved. And drying of the foodstuffs as a result of evaporation is reduced.

How does liquid packaging work?

Vacuum packaging is not limited to solids. Liquids such as oil, sauces, remoulades or dressings can also be packaged under vacuum.

Packaging these goods presents special challenges. In order to prevent the liquids leaking during the packaging process, the bags are positioned vertically or inclined inside the vacuum chamber. Moreover, liquids and wet products carry the risk of boiling during vacuuming. This needs to be prevented in order to avoid damage to the product.

How does vacuum packaging of medical devices and equipment work?

Vacuum packaging plays an important role in medical environments where a high level of hygiene is indispensable. Medical equipment packaged under vacuum is kept safe from accidental spills or splatters and other potential sources of contamination. Vacuum packaging thus helps to keep medical devices, surgical tools and personal protective equipment sterile.

It also effectively protects items from other environmental influences such as humidity and can, for example, help to prevent condensation during storage.

Vacuum packaging is also a quick and space-saving method of packaging. This makes it ideal for hospital use, where items like bedding and clothing need to be stored in a compact manner.

How does blister packaging work?

Vacuum can be used for thermoforming of plastic cavities or pockets for blister packaging. The packaging is usually sealed with cardboard, a lidding seal made of aluminum foil, or a printed plastic film that allows product information or branding to be displayed.

Blister packaging has the advantage of exhibiting a product while simultaneously avoiding contact with external factors such as humidity and contamination. Moreover, tampering with the packaged items can be prevented. If opaque blisters are used, the packaged product can also be protected against UV rays.

Blister packs are often used as unit-dose packaging for pharmaceuticals like tablets or capsules, but also for small consumer goods or foodstuffs.

How does currency packaging work?

Vacuum packaging is the most effective and reliable method of storing currency.

Bundles of a predefined quantity of banknotes are vacuumized. The plastic packaging can then be printed with the bank or branch's seal and a specific identity code. This makes the transport and storage of the packages traceable and safe. Theft and fraud can be prevented because a manipulated package is easily recognizable by a broken seal and an increase in air inside the plastic bag.

Vacuum packaged banknotes can be stored in a very compact way as the air is extracted and the volume of the package is thus reduced to a minimum. The packages therefore need less space and can be transported easily.

Moreover, vacuum packaging allows currencies to be protected from harmful external influences like moisture or dirt.

Decision support

What are the advantages of vacuum packaging over alternative packaging technologies?

Vacuum packaging is a cost-effective and economical way of protecting goods – both hygienically and mechanically. The air, and thus the oxygen, are evacuated from the packaging prior to it being sealed. This offers the advantage of protecting the packaged goods against the growth of oxygen-dependent bacteria, which is especially important when it comes to packaging foodstuffs. Product dehydration is also greatly reduced. Due to the limited contact with oxygen, vacuum-packaged foodstuffs keep their quality, taste, smell, and appearance for a long time, extending their shelf-life.

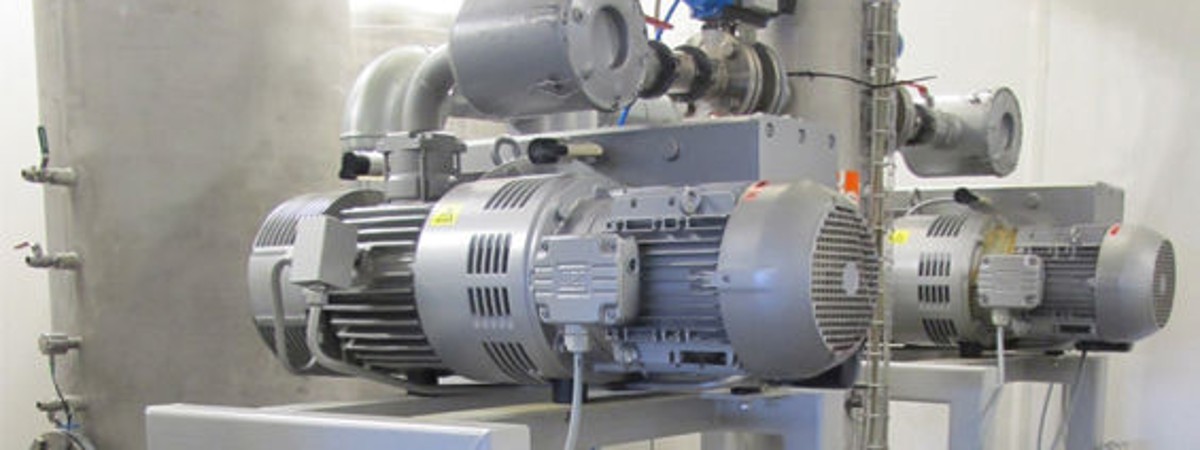

What are the best vacuum pumps for packaging?

Rotary vane vacuum pumps are the first choice for vacuum packaging. Dry screw vacuum pumps, vacuum boosters, liquid ring vacuum pumps, claw vacuum pumps and rotary lobe blowers also have specific roles in packaging. Each of them offers its own distinct advantage depending on the specific application.

What are the best vacuum pumps from Busch for the packaging process?

The most suitable vacuum generators for packaging are R5 rotary vane vacuum pumps, COBRA dry screw vacuum pumps, PANDA/PUMA vacuum boosters, MINK dry claw vacuum pumps and DOLPHIN liquid ring vacuum pumps. The choice of the optimal product depends on the specific process requirements. But also on the customer's priorities.

What are the key points to consider when buying a vacuum system for packaging purposes?

Cycle time, chamber size, pump-down time, operating time, reliability, warm-up time and availability – these factors are crucial when deciding which packaging machine to purchase. Also worth noting are the manpower required, energy and oil consumption, maintenance, and overhaul costs, and floor space.

However, there is no one-size-fits-all vacuum packaging solution. For the purpose of designing the best solution for your needs, more general factors can also be taken into consideration:

Peace of mind

The best vacuum system is the one you never have to worry about. It should deliver the required performance. And run seamlessly and reliably. This is achieved by choosing the vacuum pump best suited to the application in question and the specific requirements.

Extended lifetime

To extend the lifetime of a vacuum system, several factors should be considered. For example, the use of the right technology and the right pump configuration. Another consideration is the proper use of the system. Following the operating instructions and carrying out regular maintenance is recommended.

Saving money with a system upgrade

Your processes, including the vacuum demand, may have changed. This leads to the following questions: Is the system still in line with your needs? Is it still operating as energy-efficiently as possible? When it is time to upgrade or replace a vacuum system, it is worth looking at the entire installation. With an expert, try to identify any potential for optimization. Modern technologies can increase productivity and save money by reducing operating costs and energy consumption.

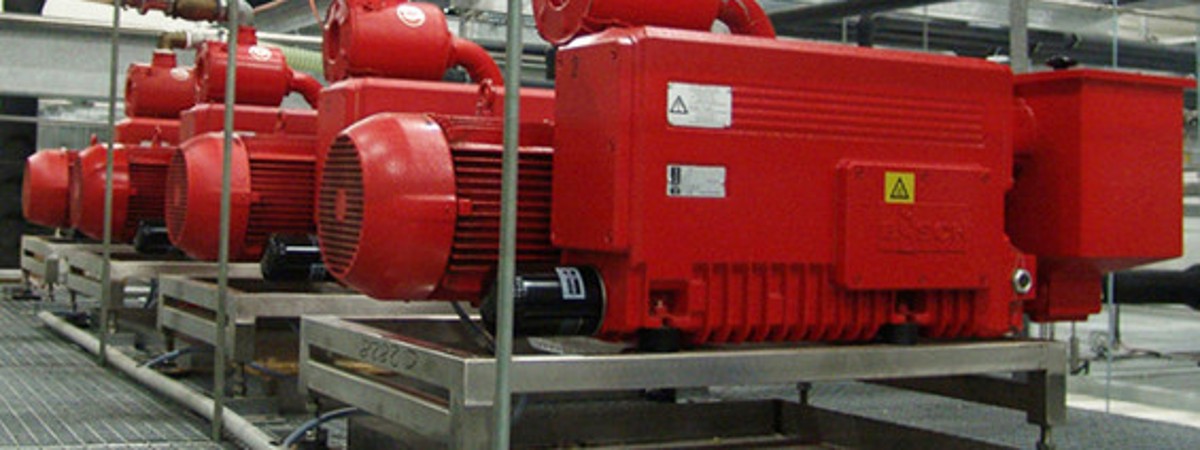

What are the benefits of central vacuum systems?

A central vacuum supply offers the potential to reduce operating costs and to increase energy efficiency.

Central vacuum systems from Busch are in operation throughout the world. In food packaging but also in many other industries. We offer turnkey solutions tailored to individual process requirements. Including pipework and control installation, together with start-up service and training for the operating team.

Are you looking for a central vacuum system to optimize your packaging process?