Fig. 1: Ralf Peter, the Technical Operating Manager of the Iffezheim waste water treatment plant, was able to reduce the energy consumption for vacuum supply by more than half at the same output. Source: Busch Vacuum Solutions.

High Energy Savings Thanks to Optimizing Control and Vacuum Technology

Wastewater treatment plant Iffezheim

The wastewater treatment plant in Iffezheim is now able to realize high energy savings. A part of the wastewater is extracted using a vacuum system because none of the treatment plant's inlets rely on a gravity flow system. Optimizing the control system and using energy-efficient vacuum technology made it possible to reduce the energy requirements for operating the vacuum system by more than half.

About the wastewater treatment plant Iffezheim

The municipal wastewater treatment plant in Iffezheim is designed for a population equivalent (PE) of 11,500. The utilization is currently approximately 5,200 PE, plus several industrial plants. The treatment plant began operation in 1984. In addition to this wastewater treatment plant, the municipality of Iffezheim also operates a ship lift, two rainwater retention basins and a sewer system with a total length of 40 kilometres. One special feature is the use of a vacuum system for extracting wastewater from two town districts. This is necessary for topographical reasons as the flat region of the Upper Rhine Plane does not have a natural downward slope that would allow wastewater to flow towards the wastewater treatment plant.

The process of wastewater extraction

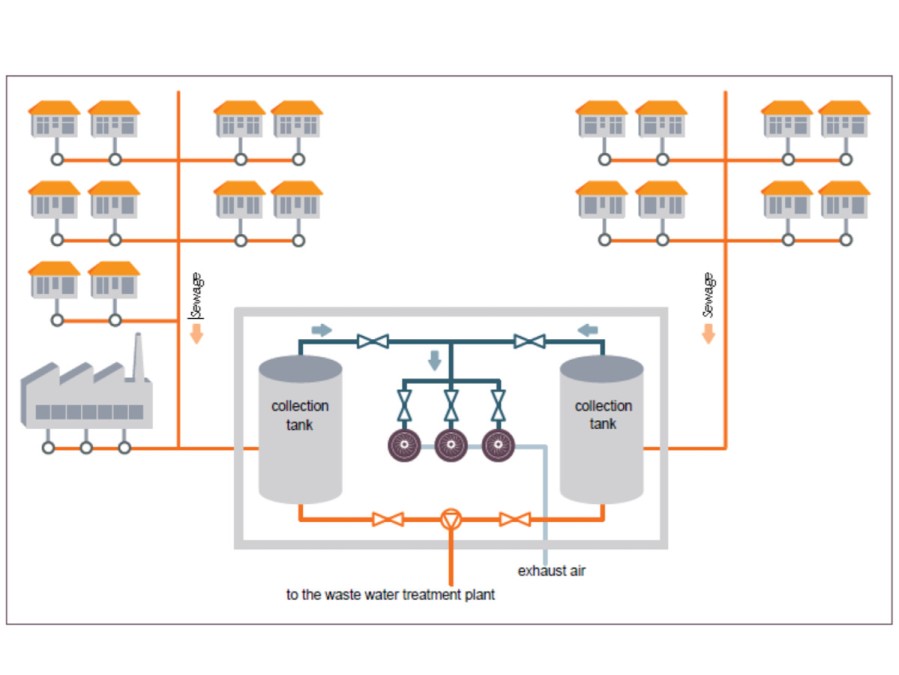

The wastewater from Iffezheim's two town districts, which are at the same elevation as the wastewater treatment plant, is drawn in using a vacuum system and collected in tanks (Fig. 2). The tanks and vacuum system are located in the ship lift building, where a gravity flow system feeds the wastewater 400 metres to the treatment plant. The larger district has two vacuum lines that lead to the collection tank. The second district is connected to the second collection tank with one vacuum line. Tap lines then branch out from the vacuum lines into the individual buildings. For each house, there are valves installed in a duct near the houses; they control when the generated wastewater is extracted. A total of 600 residents live in the buildings connected to Iffezheim's wastewater extraction system. The vacuum line network is six kilometres long. It is installed at a depth of about 80 centimetres, mainly along the course of the roads. Since the start-up of the wastewater treatment plant, the vacuum system has been equipped with three liquid ring vacuum pumps. The control system was designed to start a vacuum pump automatically to achieve the prescribed vacuum in the collecting tank. If the set point of 400 mbar absolute pressure (-0.6 bar) was not achieved within one minute, the second or third vacuum pump also began operation. The result was that all three vacuum pumps were often running simultaneously. In 2015, Ralf Peter became the Operations Manager responsible for the treatment plant. He immediately saw there was a need to optimize the control system as he recognized that the pumping speed of all three vacuum pumps together was actually too high for the normal amount of wastewater and was thus unnecessary. First, he tried to find possible leakages in the vacuum system or in the accessible part of the pipeline network, and made sure any leaks were sealed. He then changed the control system so that the first vacuum pump began operation at a pressure increase in the collecting tanks at a set point of 480 mbar absolute pressure (-0.52 bar) instead of 400 mbar. During normal operation, this vacuum pump reaches the set point and switches off again after four to seven minutes. After three to six minutes, the pressure usually rises again, and the second vacuum pump then reduces it once more. This means that, in practice, each of the three vacuum pumps operates alternately for periods of four to seven minutes. Theoretically, if there is a sudden increase in the amount of wastewater, two or all three vacuum pumps can turn on – but this operating state is an exception. Once the wastewater in one of the tanks reaches a certain fill level, a wastewater pump feeds it into the gravity flow system, through which it can then flow to the wastewater treatment plant.

-

Fig. 2: Schematic illustration of Iffezheim's waste water intake system. Source: Busch Vacuum Solutions.

Vacuum solution from Busch

Since the start-up of the vacuum system, the liquid ring vacuum pumps have been repaired, and some even replaced, several times. At the end of 2016, Operations Manager Ralf Peter contacted Dr.-Ing. K. Busch GmbH after one of the three vacuum pumps in use failed. A vacuum expert from Busch analyzed the situation on-site and then recommended a DOLPHIN liquid ring vacuum pump (Fig. 3). This series of vacuum pumps has been newly developed by Busch. It is characterized by high energy efficiency. The DOLPHIN liquid ring vacuum pump has an IE3 motor with a nominal motor rating of 5.5 kW and the same output as the plant's previously installed vacuum pumps. The previously used vacuum pumps were equipped with 7-kW motors. In July 2017, the DOLPHIN vacuum pump from Busch was installed for test purposes. After seven months of trial operation, the calculated energy savings were confirmed. Ralf Peter checked the power consumption of the new DOLPHIN vacuum pump and the two older models from another manufacturer every day. These measurements also showed the new DOLPHIN vacuum pump's significantly lower power consumption. Ralf Peter was also astonished by the low noise level of Busch's vacuum pump. Based on this positive experience, he had no doubt that he would keep the test pump from Busch. And the next time the old vacuum pumps require repairs, he also intends to replace them with new DOLPHIN liquid ring vacuum pumps. Ralf Peter has been able to reduce the daily power consumption of 190 kWh to 90 kWh by changing the control system and using a new vacuum pump from Busch (Fig. 3). Because the vacuum system runs all year long, the power consumption of the vacuum pumps used to add up to about 69,000 kWh/year. Today, close to 34,000 kWh/year are needed to run the vacuum pumps. As soon as both of the older vacuum pumps are replaced with the new Dolphin liquid ring vacuum pumps, the energy consumption will be reduced even further.

-

Fig. 3: The new energy-efficient Dolphin liquid ring vacuum pump in use during waste water extraction. Source: Busch Vacuum Solutions.

This practical example demonstrates that small investments can often result in enormous savings in the economic efficiency of a vacuum system. The most important factor in this process is a good and trusting cooperation between the operator of the wastewater treatment plant and an experienced vacuum specialist.

The vacuum specialists from Busch recommended using a modern DOLPHIN liquid ring vacuum pump for this case in particular. They use water as an operating fluid. At the Iffezheim wastewater treatment plant, the water for the vacuum pumps is conveyed in a circuit and cooled in the process. Process water from a nearby municipally owned well is used as a cost-neutral source for adding fresh water to the system. In cases where obtaining water as an operating fluid is technically and economically costlier, or not available at all, Busch also offers vacuum solutions that run completely dry and without any operating fluids.