Antipasti and delicatessen products have been the speciality of the Feinkost Dittmann delicatessen company for over 100 years. At the production site in Taunusstein, Germany, various products are manufactured as preserves in glasses or as fresh products packed in plastic trays. Vacuum supply for the packaging machines has been performed by a central vacuum system by Busch for over a year. It is considerably more economical than the vacuum technology used previously. Energy consumption alone was reduced by more than 70%.

Products in the Fresh Department are packed in plastic trays in the production building in Taunusstein. During this process, air is sucked out of the packaging trays before a CO2 N2 protective gas mixture is added to the package. Synthetic material foils are then used to give the packaging a gas tight seal before the packaging is closed with an additional plastic cover. This type of packaging guarantees that the oxygen content is under 1% thanks to the evacuation of air and use of protective gas in the packaging. This dramatically increases the products' shelf life. The product presentation with transparent packaging is also ideal because foil does not lay directly on the product or perhaps even crush the product due to the negative pressure in the packaging.

Source: © www.istockphoto.com - kabVisio.

Vacuum Supply for Food Packaging – 70% Less Energy Consumption

Feinkost Dittmann

-

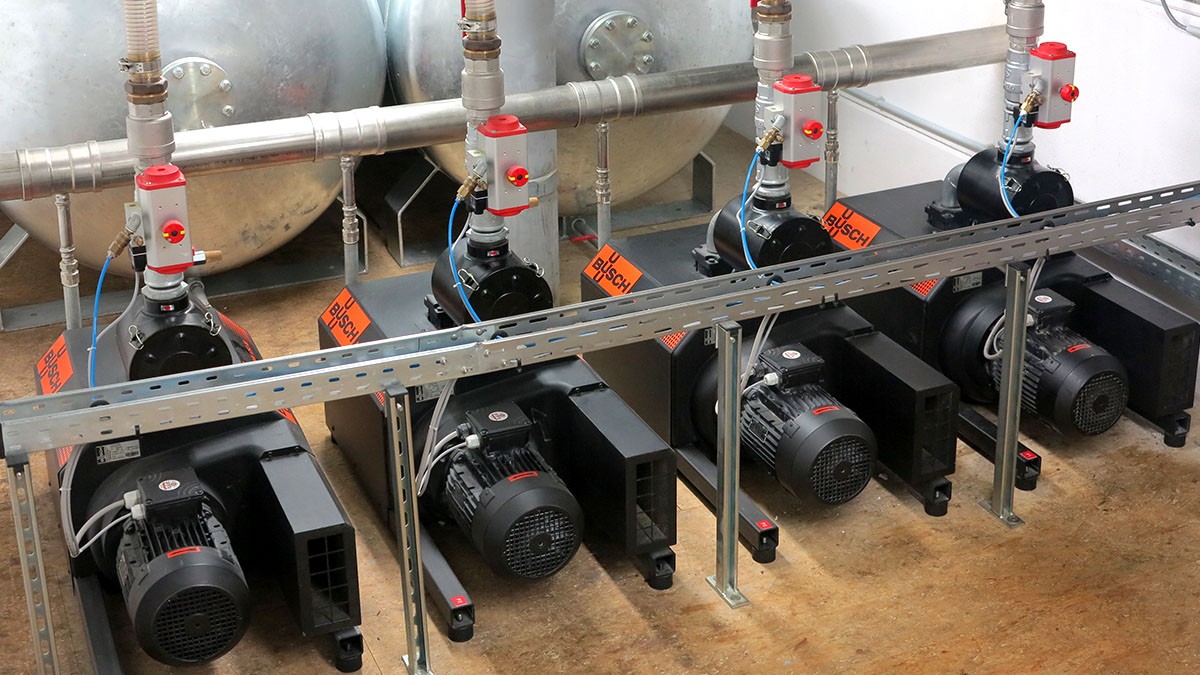

Source: Busch Vacuum Solutions.

In total, four packaging machines (tray sealers) are used for packing during two-shift operation. The vacuum required for this is generated by rotary vane vacuum pumps with 5.5 kilowatts of motor power each. They were originally installed directly on the packaging machines. For hygienic reasons and to reduce the thermal load in the production rooms, these vacuum pumps were later installed in a separate room above the production room and connected to the packaging machines using a pipe network. Andreas Lutz, the technical project manager in the production plant, was not very happy with this solution because the vacuum pumps still required high levels of maintenance. Also, fluctuations or failures in the vacuum network were first noticed if one of the packaging machines showed an error message and automatically shut down when the vacuum level was not reached quickly enough or was not reached at all. This led to repeated production downtimes on individual packaging lines.

In 2013, Andreas Lutz contacted the vacuum specialists from Busch. They were tasked with offering a more reliable and efficient solution. At the same time, continued use of the existing pipe network was to be integrated. In addition, the vacuum supply was to be designed in such a way that connection of further packaging machines would be possible if production capacity were to grow. Busch analysed the conditions on site and all technical parameters in detail and worked together closely with the project manager from Feinkost Dittmann and the in-house laboratory. The result of this analysis and comprehensive consultation was a central vacuum system with four MINK claw vacuum pumps.

-

Central vacuum system with MINK claw vacuum pumps from Busch

These have the basic advantage that they do not require an operating fluid such as oil in the compression chamber. This makes all maintenance work that has to do with oil unnecessary; for example, oil checks, oil changes, oil filter changes and the costs for procuring and disposing of oil and filters. Mink claw vacuum pumps also operate on the principle of non-contact. This means that there are no parts in the compression chamber that come into mechanical contact and thus cause wear. This renders the exchange of wear parts and the associated working hours and costs unnecessary. The non-contact operation method of claw vacuum technology also enables a high degree of efficiency and requires less motor power than conventional vacuum pumps.

This central vacuum system was installed at the end of 2013. Three vacuum containers with a volume of 3,000 litres each are upstream from the MINK claw vacuum pumps. This ensures that sufficient vacuum levels are immediately available at the machines when they are needed.

Previously, all six rotary vane vacuum pumps were in operation an average of 15 hours per day. The MINK vacuum pumps in the new central system are controlled so that only those currently needed for the actual vacuum requirements are running.

Two of the vacuum pumps with standard motors are responsible for the so-called base load. The other two vacuum pumps are frequency controlled and ensure fine adjustment of the vacuum requirements by adjusting their speed. With this intelligent solution, the pumping speed of the central vacuum system adjusts itself precisely to the current requirements.

These controls drastically reduce the actual operating times of the individual vacuum pumps because, during normal operation, all four vacuum pumps never need to operate at full load. Feinkost Dittmann's central vacuum system therefore has sufficient power reserves to connect further packaging machines. There is a plan to additionally connect a vacuum filler for glass preserves, which would eliminate the need for the current decentralized liquid ring vacuum pump installation with 7.5 kilowatt drive and thus create further energy savings.

After more than two years of operation, project manager Andreas Lutz is extremely positive when he takes stock of the situation:

Maintenance of the new central vacuum system is performed by service technicians from Busch. However, this is limited to annual measurements of the ultimate pressure and current consumption at each of the individual vacuum pumps as well as changing the upstream particle filters and an oil change in the gearbox.

This central vacuum system was installed at the end of 2013. Three vacuum containers with a volume of 3,000 litres each are upstream from the MINK claw vacuum pumps. This ensures that sufficient vacuum levels are immediately available at the machines when they are needed.

Previously, all six rotary vane vacuum pumps were in operation an average of 15 hours per day. The MINK vacuum pumps in the new central system are controlled so that only those currently needed for the actual vacuum requirements are running.

Two of the vacuum pumps with standard motors are responsible for the so-called base load. The other two vacuum pumps are frequency controlled and ensure fine adjustment of the vacuum requirements by adjusting their speed. With this intelligent solution, the pumping speed of the central vacuum system adjusts itself precisely to the current requirements.

These controls drastically reduce the actual operating times of the individual vacuum pumps because, during normal operation, all four vacuum pumps never need to operate at full load. Feinkost Dittmann's central vacuum system therefore has sufficient power reserves to connect further packaging machines. There is a plan to additionally connect a vacuum filler for glass preserves, which would eliminate the need for the current decentralized liquid ring vacuum pump installation with 7.5 kilowatt drive and thus create further energy savings.

After more than two years of operation, project manager Andreas Lutz is extremely positive when he takes stock of the situation:

- Reduction of energy requirements by more than 70%

- Drastic reduction of maintenance efforts

- Increased reliability

- No failures or breakdowns

Maintenance of the new central vacuum system is performed by service technicians from Busch. However, this is limited to annual measurements of the ultimate pressure and current consumption at each of the individual vacuum pumps as well as changing the upstream particle filters and an oil change in the gearbox.

About Feinkost Dittmann

The history of Feinkost Dittmann (Reichold Feinkost GmbH) goes back to 1901, when Carl Dittmann opened a delicatessen business in Wiesbaden, Germany. Today, Feinkost Dittmann is the German market leader for olives, antipasti, capers, garlic and anchovy specialities and the most popular delicatessen brand in the German trade market. The family-run business has its headquarters in Diez, Germany, near Limburg an der Lahn. The German production plant is in Taunusstein near Wiesbaden, where a total of 320 employees produce different antipasti specialities made, for example, from olives, feta cheese, garlic, pepper or dried tomatoes and many other delicacies. In turn, these are sent to national and international retail store chains and discount stores under the company's various own brand names. The family business currently exports its diverse specialities to over 30 countries worldwide. Feinkost Dittmann also produces delicatessen products at its own facilities in Spain, Greece and Turkey.-

Feinkost Dittmann production building in Taunusstein