Pressure-Controlled Vacuum Technology Helps Save Energy

IAC Group AB

Gothenburg, Sweden

|

June 24, 2020

A long-term test made it clear: Considerable energy savings are possible with Busch's new

R5 RA 0840 A PLUS rotary vane vacuum pump. The automotive supplier

IAC Group AB is using the new rotary vane vacuum pump on one of its

laminating systems, which produce cockpits for various Volvo models.

The vacuum pump's integrated pressure control allows operation according to demand, which resulted in monthly electricity cost savings of over 50 percent.

The IAC Group is a global supplier for the automotive industry, with more than 50 manufacturing plants and 22,000 employees. At the Gothenburg plant, 650 employees manufacture mainly cockpits and interior door panels for Volvo and deliver them just-in-time several times a day directly to Volvo's production line.

Until now, two conventional rotary vane vacuum pumps were installed on a laminating system for cockpits (Fig. 1). These vacuum pumps were unregulated and permanently in three-shift operation, five days a week. The vacuum keeps the decorative film and the base film in the desired position after manual insertion into the mold. As each vacuum pump was equipped with a 15-kilowatt motor, the power consumption per year amounted to approximately 120,000 kWh. Since the two vacuum pumps were already around 30 years old, it was time for a general overhaul or the purchase of a replacement. Maintenance manager Markel Jordansson asked Busch Vacuum Solutions for a practical and cost-efficient solution. Busch's vacuum experts recommended the newly developed

R5 PLUS (Fig. 2).

It is an oil-lubricated rotary vane vacuum pump – a robust vacuum technology that has been proven in industry over many decades.

One of the fundamental benefits of rotary vane vacuum technology is that power consumption drops as pressure falls.

The highest power consumption occurs between atmospheric pressure (when switching on) and a vacuum level of 300 mbar. Within the actual working range from 30 to 40 mbar, the vacuum pump consumes only about 70 percent of the specified nominal motor rating.

This new development from Busch is equipped with an integrated control system as standard. Depending on the pressure, it can accurately maintain a preset vacuum level or permanently guarantee a certain pumping speed at a given rotational speed.

Markel Jordansson decided to test this vacuum pump for several months. Operation with pressure control should ensure that the specified target pressure of 30 mbar at the vacuum pump is reliably maintained, regardless of the actual pumping speed required for the various process steps.

During the production process on the laminating system, which produces around 200 cockpits each day, it was practically impossible to determine the actual pumping speed in advance. A total of eight process steps are carried out on the system, which are not synchronized with each other and require different pumping speeds. Previously, a vacuum level of 40 mbar was specified directly at the mold for

holding the inserted molded parts. As the vacuum supply is not installed directly on the laminating system, leakages occur in the longer vacuum line. This means that the vacuum pump itself must provide a vacuum level of 30 mbar.

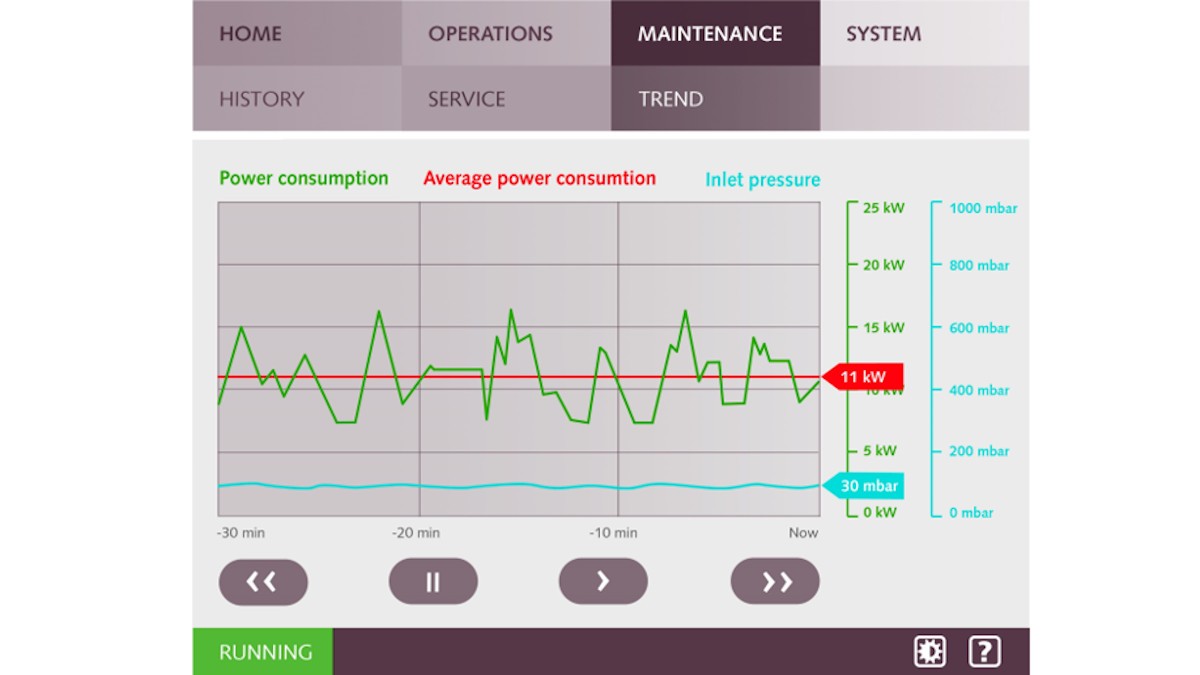

As the R5 PLUS began operating, it was possible to see the required rotational speed and thus the pumping speed permanently on the display. A vacuum level of 30 mbar was programmed. It was quickly recognized that the need for pumping speed varies greatly depending on the process steps and that the vacuum pump compensates for this by changing the rotational speed. The built-in PLC records all operation-related data and can be accessed at any time on the display (Fig. 3), read out with the integrated memory card, or transmitted to the system control or other external output devices. Maintenance manager Markel Jordansson has also activated the Eco mode, which automatically switches off the vacuum pump after a freely selectable period of time, during which the process requires no power from the vacuum pump. As soon as vacuum is required again by the process, the vacuum pump automatically starts up and adjusts to the required rotational speed. This is particularly energy-saving during short production interruptions and breaks. Previously during such times, two vacuum pumps ran continuously at 100 percent output. Markel Jordansson has had an electrical engineer calculate the energy savings internally and can prove that using the new R5 PLUS rotary vane vacuum pump saves EUR 8,400 per year in energy costs. This does not include further savings potential through process optimization. The vacuum pump can now be fine-tuned thanks to the continuous recording of the ultimate pressure and the power consumption, along with several other parameters. Originally, for example, 30 mbar working pressure was required directly at the mold, but after a few weeks it was found out that 40 mbar was sufficient for this application. Now, if a rougher vacuum level is specified, the vacuum pump responds with even lower rotational speeds and even lower energy consumption.

Another major benefit for Markel Jordansson is the significantly lower noise emission of the new R5 PLUS compared to the older vacuum pumps previously used.

Both of the two old rotary vane vacuum pumps had noise levels of 79 dB(A), which made it impossible to have a conversation in the pump room, says Markel Jordansson. Even at maximum rotational speed, the R5 PLUS emits no more than around 70 dB(A).

After the first few months of testing, maintenance manager Markel Jordansson became confident that the R5 PLUS is the ideal vacuum pump for his application.

Gothenburg, Sweden

|

June 24, 2020