Hygienic removal of dead fish in RAS

Osland Settefisk SA

Bjordal, Norway

|

March 15, 2017

|

4 min

Osland Settefisk SA produces

8,500 tonnes of fish annually in its breeding facilities in Bjordal on the Sognefjord in Norway and in various off-shore enclosures. Since June 2016, the new, state-of-the-art RAS (

Recirculating Aquaculture System) has been in operation in the

custom-built breeding building. There, salmon are cultivated from when they hatch until they become smolt. To remove dead fish and contamination from the tanks, Osland Settefisk installed a pneumatic extraction unit from Busch Vacuum Solutions that enables hygienic removal of dead animals

Osland Settefisk installed a pneumatic extraction unit from Busch Vacuum Solutions that enables hygienic removal of dead animals

so that they can be processed.

Osland Settefisk production

Osland Settefisk was founded in 1987 and specialises in breeding salmon and rainbow trout. At the Bjordal site,

3,500 tonnes of trout are nurtured in an external installation each year until they are ready for slaughter. While the trout eggs come from the company’s own breeding stock, the salmon eggs are purchased and remain in the company’s hatchery until the fry hatch. Afterwards, the fry that weigh up to approximately ten grams are put into smaller stock feeding tanks before they are placed in larger growing tanks, where they reach weights of 40 to 50 grams.

3.5 million smolt are farmed each year at this facility and then taken by truck on a short ride to the wellboat that brings them to the off-shore net catches. There, the salmon grow to their slaughter weight of four to six kilograms. Osland Settefisk then sells the live fish to slaughterhouses and processing plants.

Just like many of its customers, Osland Settefisk is part of the

Norwegian Salmon Group. This ensures a

higher quality standard for the produced fish products because consistently strict quality guidelines are followed from the fishery to the finished product during breeding, feeding and processing.

Our solution for removal of dead fish

To be able to quickly and hygienically remove dead fish from the stocking feed and growing tanks, Operations Manager Kjetil Rørtveit looked for a technical solution, which Busch Vacuum Solutions from Drøbak then provided. It developed an

extraction system that was installed in an adjoining room.

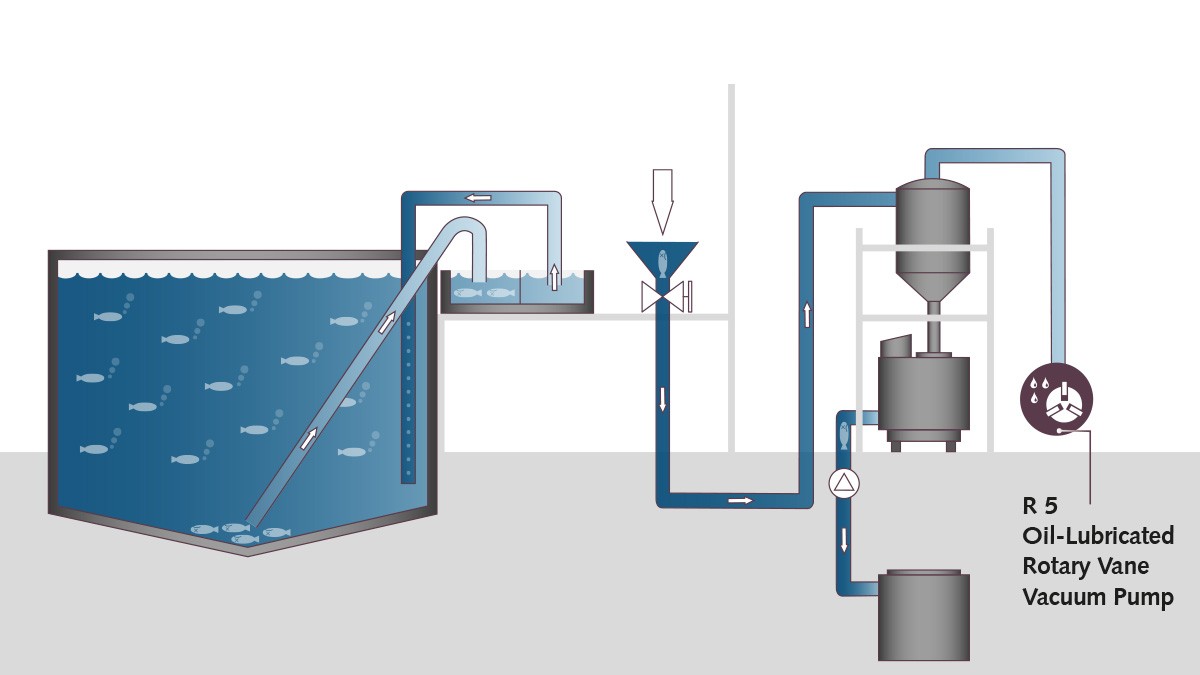

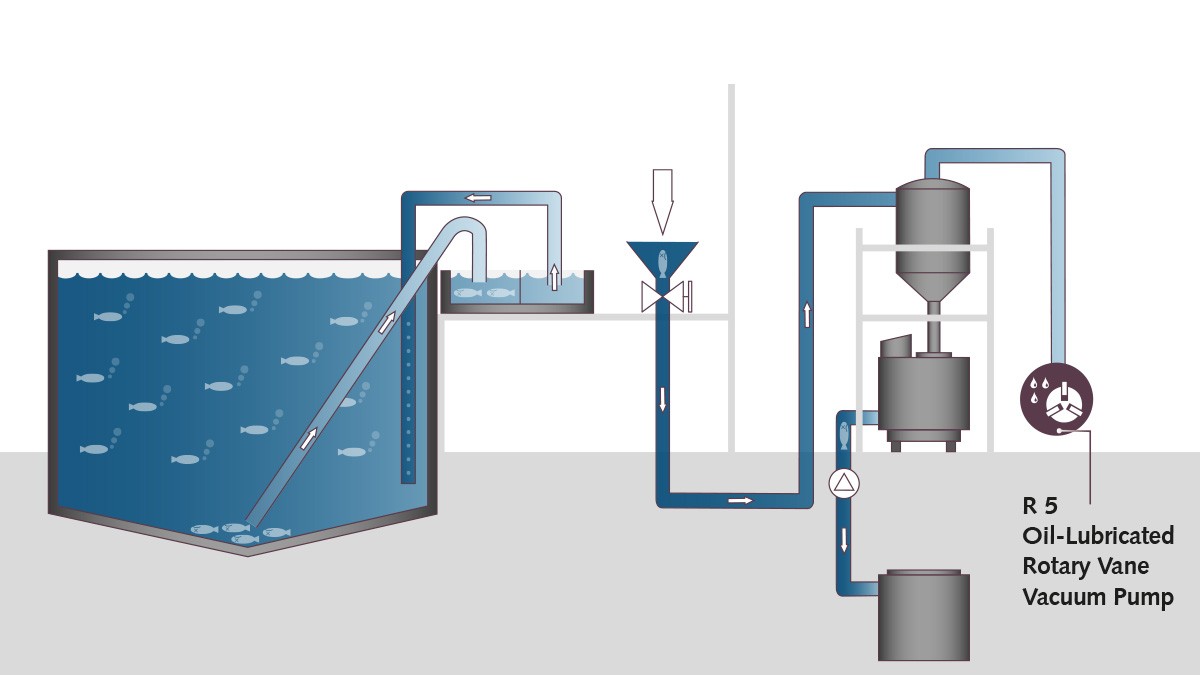

- Dead or injured fish sink to the deepest part of the tank where they are constantly removed with water.

- Then they are being transported to a collecting tank while the water is then returned to the tank.

- This makes it possible to continuously check whether dead fish are in the collecting tank.

- Then they are then manually removed with a net and placed in an infeed station directly beside the collecting tank (Fig. 1).

The infeed stations at each tank are connected to the extraction system in a separate room using pipe lines (Fig.2). This mainly consists of a cyclon separator, a tank and an

R5 rotary vane vacuum pump. This vacuum pump from Busch

constantly maintains a vacuum in the pipework.

- If fish are put into an infeed station and the valve opens, they are quickly removed without residue using the pipe line and they are then transported to the cyclon separator.

- Once this has reached a certain fill level, a valve disconnects the cyclon separator from the extraction system and ventilates it to atmospheric pressure.

- A valve under the cyclon separator opens and the dead fish land in the containers located underneath.

- The fish are shredded there and mixed with a metered mixture of formic and lignosulphonic acid.

This enables the

pH value to be controlled and

oxidation can be slowed down. The resulting substance is used as a by-product in food production and is automatically extracted from the mixer into a transport container. The company Krüger Kaldnes designed and realised the complete RAS. Vacuum experts from Busch worked closely with the engineers of Krüger Kaldnes to design the waste extraction system.

Benefits of the new extraction system

Busch offers individually designed extraction systems for fish breeding facilities of all sizes.

Busch offers individually designed extraction

systems (Fig. 3) for fish breeding facilities of all sizes. These are connected to the RAS control so they are completely integrated into the operating control. A total of four infeed stations for dead fish are installed at Osland Settefisk.

Their maximum distance to the extraction station is 50 metres. All PVC extraction pipes have a diameter of 110 millimetres. For this plant size, Busch Vacuum Solutions uses an

R5 rotary vane vacuum pump with a

pumping speed of 100 cubic metres per hour. These vacuum pumps are available in many sizes, so they can be precisely adjusted to fit the requirements and the size of the extraction systems.

Thanks to the system control, it is possible to install a relatively small vacuum pump, which has a

positive effect on energy consumption.

Bjordal, Norway

|

March 15, 2017

|

4 min