Fine Ham Perfectly Packaged

Basedahl Schinkenmanufaktur

Hollenstedt, Germany

|

April 05, 2020

|

4 min

Henning Basedahl's business card identifies him simply as a "Schinkenhöker" – which, in the Low German dialect, means simple merchant. Mr. Basedahl is the owner of Basedahl Schinkenmanufaktur (ham factory) in Hollenstedt – a small town between Hamburg and Bremen. He is the second generation of his family to produce a very special delicacy: an exceptionally mild yet flavorsome ham accentuated by a light smoky flavor. When it comes to packaging, Basedahl makes as few compromises as he does in the production of his ham.

To make sure he achieved the best packaging results, he was one of the first ever to have a new

R5 RD 0360 A rotary vane vacuum pump from Busch Vacuum Solutions installed for his chamber vacuum machine.

About Basedahl ham factory

The Basedahl ham factory produces around 20,000 hams each year. And as the "Manu-" aspect of its German name Manufaktur suggests, at Basedahl everything really is still made by hand. The company sells its ham in its own little shop directly in Hollenstedt. In the greater Hamburg area, Basedahl sells its speciality to selected retail and delicatessen shops, making the deliveries using its own vehicle. However, customers also include retail and delicatessen shops throughout Germany. For example, Basedahl has been supplying Käfer Feinkost in Munich since 1990. Strict quality control is a guarantee for the high standard of Basedahl ham. As a matter of principle, only hams from sows selected by two slaughterhouses in the region from farms in Lower Saxony, North Rhine-Westphalia or Denmark are used. Each ham is personally inspected by the boss (Fig. 1). The selection criteria are stringent. It can sometimes happen that a quarter of a raw ham delivery is returned to the slaughterhouse due to its failure to meet the quality requirements. The recipe, according to the ham specialists from Hollenstedt, is simple: take the ingredients of salt, smoke, love and time and mix them with stringent quality control and careful handcraft.

Packaging takes place three days a week, for seven hours on each day. Shrink bags are used for packaging units from 50 grams to eight kilograms (Fig. 2). The chamber volume is dimensioned in such a way that four eight-kilogram bags can be stored together.

Vacuum technology in the manufacturing process

The vacuum pump previously installed in the packaging machine had a pumping speed of 300 cubic meters per hour and reached a theoretical ultimate pressure of 0.5 millibar. Felix Engel, plant manager at Basedahl and also responsible for technology, noticed that this vacuum pump no longer reached the specified ultimate pressure with increasing running time and was losing a lot of oil. The vacuum pump was also very loud and its heat radiation had to be dissipated via the air conditioning system.

It was therefore removed from the packaging machine and placed one floor above it. This at least solved the problem with the oil and noise emissions. However, the vacuum level in the packaging chamber was not improved, even by extending the pump-down times.

Busch vacuum solution and its benefits for the customer

That is why Mr. Engel tried to find an alternative in 2017. He found it in the

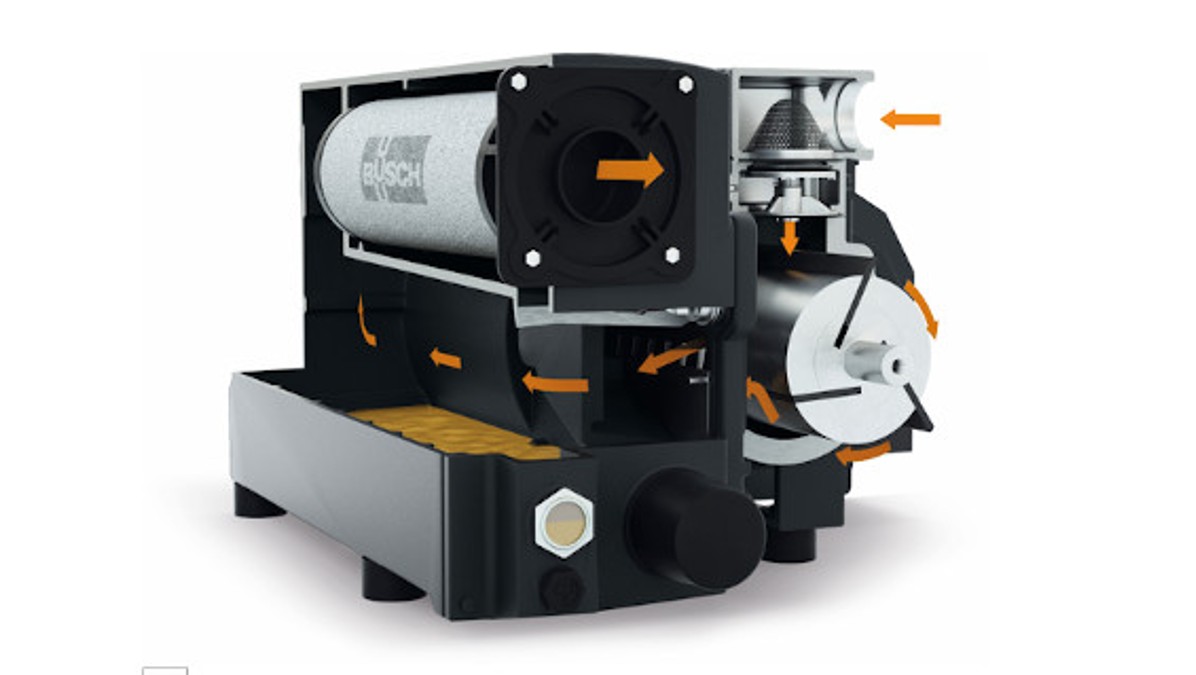

R5 RD 0360 A rotary vane vacuum pump from Busch Vacuum Solutions (Fig. 3), which was new to the market at the time. The newly developed vacuum pump was not officially presented by Busch at the IFFA in Frankfurt until the year after. In August 2017, one of the first of these vacuum pumps worldwide was installed at Basedahl.

This vacuum pump has a pumping speed of 300 cubic meters per hour and is driven by a 5.1-kilowatt motor. The previously used vacuum pump had a slightly higher motorization with a 5.5-kilowatt motor. At 0.1 millibar, the new vacuum pump achieves a lower vacuum than the previous vacuum pump.

In the packaging itself, a vacuum level of 5 to 7 millibar is perfectly adequate, but the pumping speed and the ultimate pressure (vacuum) of a vacuum pump are interdependent. The lower the ultimate pressure reached by a vacuum pump, the higher the pumping speed at the pressure at which packaging is performed, i.e. at 5 to 7 millibars.

This is a technical reality that has the advantage in practice of reducing evacuation time at a lower ultimate pressure, thus making the packaging cycle faster – a fact that Felix Engel was pleased to notice immediately upon installing the new vacuum pump.

Noise emissions had also been reduced, too. While the previous vacuum pump had a noise level of 76 dB(A), the R5 RD 0360 A runs at 70 dB(A). With the new development of the R5 RD series, Busch has also developed a new oil separation concept and optimized the filtration technology (Fig. 4). The filtration system was adapted to

Busch's synthetic oil VSL. This polyalphaolefin-based oil (PAO) is specially designed for

rotary vane vacuum pumps used in the vacuum packaging of food products. It is certified according to NSF standard H1 and has a service life four times longer than comparable mineral oils.

Felix Engel leaves the maintenance of the vacuum pump to a Busch service technician. This is done once a year as a precautionary measure. Otherwise, he relies on Busch quality because downtime is totally unacceptable – the gourmets out there don't want to wait to get their hands on his hams.

Hollenstedt, Germany

|

April 05, 2020

|

4 min