As a comprehensive supplier, EG Fleischwarenfabrik Dieter Hein GmbH & Co. KG produces a wide array of meat and sausage specialities for customers across Europe and the US.

As a company with environmental awareness, it has always been striving towards energy-efficient production and preserving resources. For this reason, it already centralised the vacuum supply for its packaging machines several years ago, consequently tapping into huge energy-saving potential.

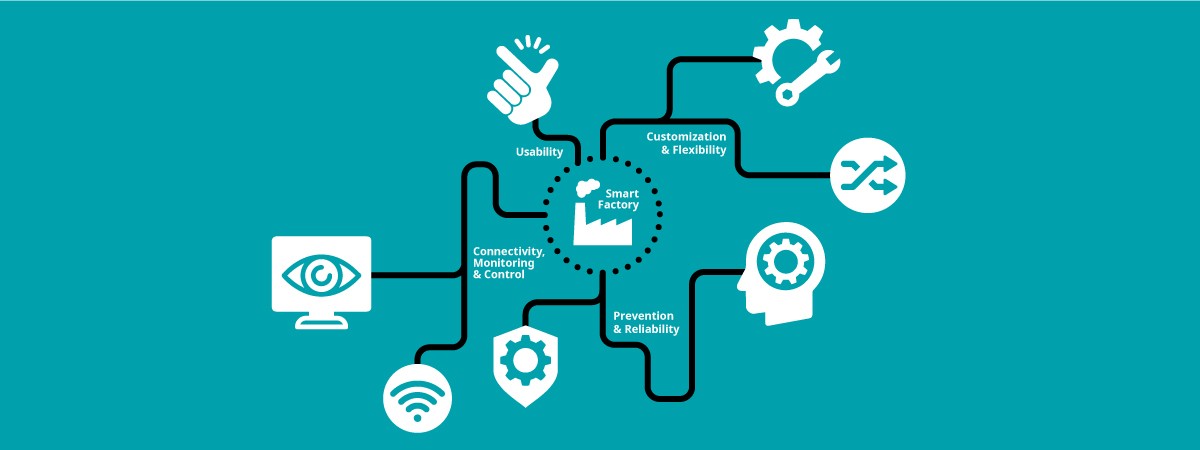

Dieter Hein is Germany's first-ever meat processor to pilot Busch's new R5 RA 0840 A PLUS vacuum pump in its central vacuum system, enabling the company to save even more energy. What's more, this vacuum pump is ready for Industry 4.0, equipped with built-in pressure control and a PLC.

Source: Busch Vacuum Solutions.

Self-Regulating Vacuum Pump Helps Save Energy

Ready for Industry 4.0

About Dieter Hein

The story of Fleischwarenfabrik Dieter Hein began over 80 years ago, with a butchers' shop in Görlitz established by master butcher Georg Hein. His son Dieter Hein continued the tradition, opening a small shop in Osnabrück in 1961. The next step in the company's development was the inauguration of the current meat production factory in Hasbergen on the outskirts of Osnabrück in 1975. A second production facility opened in Görlitz in 1996.As a comprehensive supplier, Dieter Hein produces cold cuts of meat for wholesalers, ranging from ready-to-serve roast convenience foods – such as meat balls, kebab meat burgers and crispy sliced bacon – to speciality produce for delicatessens, such as uncooked, cold meat, ham, roast meats, turkey and much more (fig. 1).

-

Fig. 1: EG Fleischwarenfabrik Dieter Hein GmbH & Co. KG.

Vacuum packaging process

The more than 300 staff at the processing plant in Hasbergen work in three shifts, whereby the third shift is tasked with cleaning. Produce is packaged using a total of nine automatic thermoforming machines. These units are connected to a central, fully automatic, on-demand vacuum supply.A vacuum pumping unit generates the rough vacuum for pre-evacuating the packaging chambers to 45 millibars. Control valves activate a fine vacuum pumping unit as soon as the system has generated the 45 millibars at which point a second evacuation process starts to reduce the conditions in the packaging to a vacuum level of 3 to 4 millibars. A third vacuum module generates the vacuum for thermoforming the base foil in the forming station of each individual packaging machine.

In an effort to cut the energy consumption even further, Thomas Pelke – as the head of maintenance – and Bernd Wörner – the head of the energy division – decided to trial Busch's new R5 RA 0760 A PLUS (fig. 2) rotary vane vacuum pump.

About the R5 PLUS

- Presented to trade specialists at the IFFA fair in Frankfurt/Main, this vacuum pump features a frequency-controlled motor and an integrated control unit as standard.

- A pressure sensor permanently measures the vacuum level at the inlet to the vacuum pump. As a result, the R5 0760 A PLUS can quickly respond to any change in demand by adapting the pumping speed to current requirements.

- The control range stretches from 35 to 60 hertz, equivalent to a pumping speed of 440 to 760 cubic metres per hour.

-

Fig. 2: The new Busch R5 RA 0760 A PLUS vacuum pump has been installed in an existing central vacuum system as part of a pilot project. Source: Busch Vacuum Solutions.

The new vacuum pump was integrated into the central vacuum supply at the end of 2018, replacing the unregulated rotary vane vacuum pump with a pumping speed of 630 cubic metres per hour. Installed over 20 years ago, this pump used to be responsible for maintaining the system's rough vacuum. The new vacuum pump has not been connected to the central vacuum supply's control unit as it is self-regulating. The control system was programmed using the built-in display, though this was restricted to setting the required vacuum level to 45 millibars.

Self-regulating of pumping speed

In the previously installed, central vacuum system, the rough vacuum tended to fail when multiple packaging machines suddenly required a high pumping speed and the vacuum pump had already been switched off because the required vacuum level had been reached. As a result, the unregulated vacuum pump had to restart first and it consequently took longer to reach the full pumping speed of 630 cubic metres per hour. The new R5 RA 0760 A PLUS maintains a speed of 35 hertz. At this speed, the vacuum pump consumes roughly 60 to 70 percent of the nominal motor rating of 18.5 kilowatts while also maintaining the selected vacuum level. So, if the pumping speed suddenly increases – for instance, if several packaging machines are switched on at the same time to operate at the same speed – the R5 PLUS reacts straight away and can increase the output up to 120 percent until the surge in demand has been satisfied.

High quality display for control and monitoring

The 7.5-inch display lets Bernd Wörner keep an eye on the recorded data at all times. Wörner has realised that, on average, the R5 PLUS runs at just 60 percent of its capacity. It consumes just 60 to 70 percent of the nominal motor rating in electrical power because it maintains the selected vacuum level. On this basis, the vacuum pump's motor actually consumes roughly 6 to 8 kilowatts. This figure is shown directly on the display – a particularly useful feature when you want to achieve maximum energy savings during operation without having a negative impact on the packaging quality or cycle time.

Data analysis

The company can also analyse data recorded over an extended period because data is permanently stored on the integrated PLC. Data can be printed out in tables or graphs at any time.

Very low noise level

Bernd Wörner also noticed yet another benefit as soon as they started up the pump, noting that "the pump is practically silent." To be precise, the vacuum pump generates a noise level of just 70 dB(A) at top speed.

Benefits of the integrated intelligent vacuum pump

It only took a few weeks of operating time for the benefits of this intelligent vacuum pump to come to the fore.Self-regulating of pumping speed

In the previously installed, central vacuum system, the rough vacuum tended to fail when multiple packaging machines suddenly required a high pumping speed and the vacuum pump had already been switched off because the required vacuum level had been reached. As a result, the unregulated vacuum pump had to restart first and it consequently took longer to reach the full pumping speed of 630 cubic metres per hour. The new R5 RA 0760 A PLUS maintains a speed of 35 hertz. At this speed, the vacuum pump consumes roughly 60 to 70 percent of the nominal motor rating of 18.5 kilowatts while also maintaining the selected vacuum level. So, if the pumping speed suddenly increases – for instance, if several packaging machines are switched on at the same time to operate at the same speed – the R5 PLUS reacts straight away and can increase the output up to 120 percent until the surge in demand has been satisfied.

High quality display for control and monitoring

The 7.5-inch display lets Bernd Wörner keep an eye on the recorded data at all times. Wörner has realised that, on average, the R5 PLUS runs at just 60 percent of its capacity. It consumes just 60 to 70 percent of the nominal motor rating in electrical power because it maintains the selected vacuum level. On this basis, the vacuum pump's motor actually consumes roughly 6 to 8 kilowatts. This figure is shown directly on the display – a particularly useful feature when you want to achieve maximum energy savings during operation without having a negative impact on the packaging quality or cycle time.

Data analysis

The company can also analyse data recorded over an extended period because data is permanently stored on the integrated PLC. Data can be printed out in tables or graphs at any time.

Very low noise level

Bernd Wörner also noticed yet another benefit as soon as they started up the pump, noting that "the pump is practically silent." To be precise, the vacuum pump generates a noise level of just 70 dB(A) at top speed.