Safe and Fast Mooring of Vessels and Ferries with Vacuum Technology

Cavotec Specimas SpA

Maulburg, Germany

|

24.03.2015

|

4 min

Cavotec Specimas SpA has developed an automated vessel mooring system which enables ships to be held securely to harbour quays by vacuum. MoorMaster™ systems are used worldwide to moor ships rapidly and safely – and without hawsers or mooring lines. The vacuum technology employed is critical:

Cavotec relies on Busch vacuum systems, and uses MINK claw vacuum pumps in its MoorMaster™ units.

About the MoorMaster™ system

The MoorMaster™ system was developed in New Zealand in 1998, and was first used in Wellington and Picton harbours to secure ferries to the quay by suction pads. This revolutionary idea proved to be highly successful, and since then many MoorMaster™ systems have been installed throughout the world. Engineering, development and round-the clock support are based in New Zealand, whilst production of complete systems is carried out in Nova Milanese (MI) in Italy.

This mooring technique offers many advantages. Firstly, the time taken to berth a vessel is drastically reduced. The mooring times for large freighters varies according to prevailing conditions, but can be between 20 and 90 minutes. With a MoorMaster™ system this can be reduced to seconds, and casting off can be accomplished in as little as 10 seconds. These time savings allow unloading of freighters and ferries to be started more rapidly.

In addition, mooring gangs are no longer required: the entire operation can be conducted by one person by remote control, either directly from the ship's bridge or by port personnel on land. Port workers are no longer required in the high-risk zone directly at the quay wall. Large freighters of up to 450,000 dwt (tons deadweight) or container vessels of up to 18,000 TEU (20 ft. containers) can be held securely without mooring lines by this vacuum-based automated mooring technology.

Process of Mooring with the MoorMaster™ system

In addition, the duration of tug assistance is reduced. The ship is brought to a stop parallel to the quay wall, suction pads are then extended which attach to the ship's hull and pull the vessel to the quay.

MoorMaster™ technology allows ships considerably longer than the quay to be moored securely.

MINK claw vacuum pumps in the mooring process

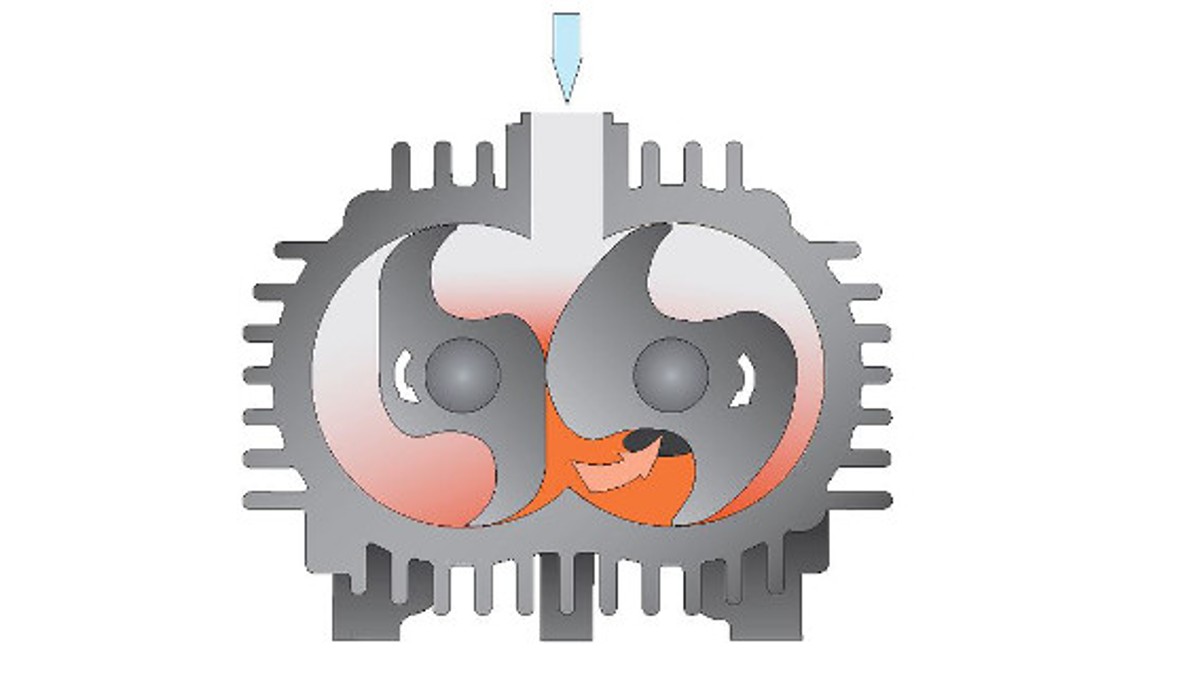

Every vacuum suction unit includes a power pack station, in which the electronics, the hydraulic pumps and the

MINK claw vacuum pumps are installed.

The MINK claw vacuum pumps apply immediate high vacuum which the vessel can be drawn to the quay and held securely.

An electronic control system senses ship movements caused by tides, draft changes, currents, waves or wind, and compensates using a sophisticated hydraulic system.

The MINK claw vacuum pumps have the task of applying immediate high vacuum when the suction pads attach to the ship's hull, providing a strong seal with which the vessel can be drawn to the quay and held securely. A vacuum reservoir within the power pack station guarantees a permanent reserve supply – even if a power supply fails, the connection between ship and suction pad is maintained.

The first tests of MoorMaster™ systems used oil-lubricated rotary vane vacuum pumps, which proved to be unreliable. Any seawater drawn into the pumps tended to mix with the vacuum pump oil, causing a drop in system output. This problem could only be remedied by frequent oil changes.

Cavotec quickly decided to replace the rotary vane vacuum pumps with

Busch MINK claw vacuum pumps. These are

completely dry, which means no oil or other working fluids are required to generate vacuum. A special coating on the inside of the vacuum pumps provides

resistance to seawater. The working principle of MINK claw vacuum pumps permits

reliable and almost maintenance-free operation.

For Cavotec this was a crucial factor in the decision to use Busch MINK claw vacuum pumps, because the

safety and reliability of MoorMaster™ systems have top priority. The control system of every MoorMaster™ unit throughout the world is connected to the Internet and can be monitored by Cavotec around the clock, allowing faults to be recognised immediately. Cavotec service teams conduct regular inspections and maintenance on-site. Cavotec has 35 companies worldwide. Since MoorMaster™ systems commenced operation,

no problems or failures of MINK vacuum pumps have been recorded. If any were to occur, precautions have been taken: Busch owns 59 companies worldwide and operates an extensive service network, so in an emergency a service technician could be on-site rapidly.

Maulburg, Germany

|

24.03.2015

|

4 min