Busch News & Media

High Reliability and Minimal Maintenance Effort During Vacuum Generation for Material Feeding

High Reliability and Minimal Maintenance Effort During Vacuum Generation for Material Feeding

Bada AG

Bühl, Germany

|

21.03.2022

|

5 min

Bada AG produces high-quality technical thermoplastics and thermoplastic elastomers for various industries. Back in 2001, Bada AG was one of the first companies ever to use Busch's new MINK claw vacuum technology for

degassing the melt during extrusion. In 2001, it was a courageous step away from the commonly used liquid ring vacuum technology and towards the completely new dry MINK claw vacuum technology. In 2007, when Bada moved to a new company building, the existing five extrusion lines, as well as the vacuum generation for the material feed, had been completely converted to MINK claw vacuum pumps and Bada had implemented its concept of

continuous vacuum generation for the entire production.

About Bada AG

Since 1998, Bada AG has been producing high-quality technical thermoplastics and thermoplastic elastomers in the city of Bühl in southwest Germany for various industries such as automotive, electronics, sports and leisure, construction, furniture manufacturing, medical technology and household goods for customers all over the world. Bada's second plant in Spain has been producing the same compounds since 2007. Bada is a manufacturer of compounds that specializes in customized products, including small batches. Bada's expertise is in the production of compounds with exactly the properties required for the desired customer application and decisive for their function. These special compounds form a very individual product variety and require a high degree of flexibility in production in addition to the sometimes small batches. Development and testing take place in its own high-tech laboratories. With its two compounding plants in Germany and Spain, Bada can simultaneously produce a wide variety of compounds, implement rapid formulation changes on the extrusion lines and thus guarantee quick implementation of customer-specific requirements. This flexibility represents a challenge for the production processes. Martin Wunsch, head of production, emphasizes that process reliability is an absolute priority and that all production facilities are designed accordingly.

In the early years after the company was founded, Bada had installed liquid ring vacuum pumps on the extrusion lines, which were used for degassing the melt in the screw zone.

MINK vacuum solution and its benefits

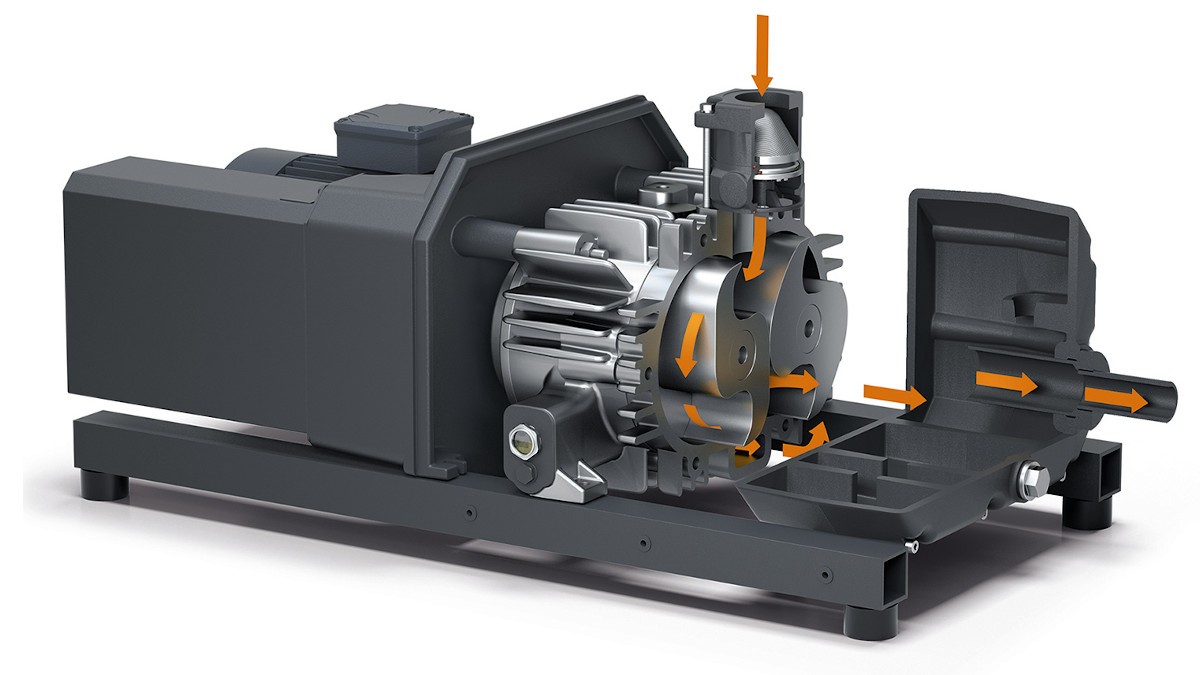

The first contact with the

MINK claw vacuum technology came in 2001 when a new extruder was purchased that was already equipped with a MINK claw vacuum pump. At the time, this was a completely new principle of vacuum generation: gases and vapors could be extracted from the melt without any operating fluid.

This operating principle thus has considerable advantages over liquid ring vacuum technology, which requires water as an operating fluid.

Considerable amounts of water were needed for every liquid ring vacuum pump. With the MINK vacuum pump, no water needs to be supplied and discharged, nor is there need for a cooled water circuit. This eliminates all associated costs such as installation, consumption, control and maintenance of the water supply.

Alain Guckert, Maintenance Manager

During degassing of the melt in the screw zone of the extruder, mainly residual monomers, moisture, fats and waxes are extracted. With the liquid ring vacuum pump, there is a risk that volatile components of this vapor/gas mixture might dissolve in the water, thus making the disposal of the water even more expensive.

Nowadays, a total of 14 twin-screw extruders are used in both plants for three-shift operation. The nominal capacity of these extruders in the current product portfolio is 40,000 tons per year. Each extruder has an upstream gravimetric dosing system. It ensures a high level of formula and color reproducibility. With an average batch size of 2,000 and 4,000 kilograms, a formula change is required up to twelve times a day.

The fully automatic material feed from the silos via mixers and dosing units into the extruders, as well as the transport of the finished compounds after the granulator into the packaging silo, take place using MINK claw vacuum pumps, which are all installed in an easily accessible manner. Since work is carried out in three-shift operation six days a week, all vacuum pumps are permanently in operation during this time. The quantity of conveying air is controlled fully automatically via valves that more or less open or close depending on the formulation and its changing base materials and quantities. This ensures that the raw materials are transported through the pipes as gently and safely as possible in the ideal conveying flow. Alain Guckert, maintenance manager, praises the absolute reliability of the MINK vacuum pumps which, despite the long operating times, provide the required pumping speed and maintain the defined vacuum level without any complaints. As maintenance manager, Alain Guckert is responsible for the trouble-free operation and maintenance of the MINK vacuum pumps. Since a malfunction with or failure of one of the vacuum pumps would immediately lead to a production interruption on an extrusion line, he proceeds extremely carefully and carries out a visual inspection on a daily basis. The inlet filters are cleaned or replaced quarterly and the gear oil is changed once a year as a precautionary measure. According to Alain Guckert, this represents minimal effort compared to other types of vacuum pumps.

The advantages of being limited to just one pump type for vacuum generation are obvious for production manager Martin Wunsch. The in-house maintenance team can concentrate on this type. For years, MINK claw vacuum pumps have been working on material feeding without any malfunctions. Use of the same vacuum pumps in extruder degassing often requires rinsing or cleaning due to the different compounds produced. Despite the upstream cyclone separator, it is not always possible to prevent volatile components of the vapor from penetrating the vacuum pump and cracking there. Alain Guckert has mobile replacement pumps available for this case so that a cracked vacuum pump can be changed immediately. The MINK vacuum pump's functional design makes it easy for the internal maintenance team to open and clean.

Bühl, Germany

|

21.03.2022

|

5 min