- Tecnología de sobrepresión de paletas rotativas de funcionamiento en seco

- Generación de vacío fiable libre de aceite

- Construcción robusta

- Cojinetes lubricados de por vida

- Dimensiones compactas

- Fabricación precisa de primera clase

SECO

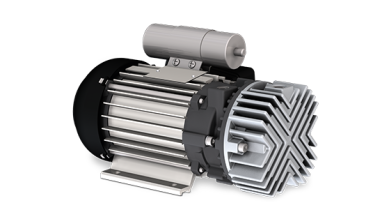

Bombas de vacío y compresores de paletas rotativas en seco

Compactas, fiables y extremadamente potentes: estas son las características distintivas de los compresores y las bombas de vacío de paletas rotativas en seco SECO. Gracias a su principio de funcionamiento exento de lubricante, se pueden utilizar en numerosas aplicaciones industriales en las que se requiera un vacío o aire comprimido rápido y limpio. La familia SECO está formada por bombas de vacío y compresores.

Hemos desarrollado y optimizado continuamente nuestra tecnología de paletas rotativas en seco durante más de 30 años. Los beneficios del perfeccionamiento permanente del producto son altos niveles de disponibilidad y un mejor rendimiento.

Las bombas de vacío y los compresores SECO se caracterizan por su construcción robusta y sus rodamientos lubricados de por vida.

Principio de funcionamiento

En un cuerpo cilíndrico se monta excéntricamente un rotor con varias paletas. A medida que el rotor gira constantemente, las paletas se deslizan y forman cámaras entre ellas y el cuerpo.El medio bombeado se absorbe y queda atrapado dentro de estas cámaras. Se comprime a través de la rotación en curso y se transporta a la salida. El sellado se logra mediante paletas autolubricantes de alto rendimiento.

SECO SD

Ventajas de la serie SECO SD

Los compresores SECO SD de paletas rotativas de funcionamiento en seco son la elección ideal para cualquier aplicación en la que se requiera una compresión fiable, libre de aceite y de pulsaciones. Son perfectamente adecuados para la aireación de líquidos, como el tratamiento de aguas residuales, la impresión y la conversión de papel.

Gracias a las paletas autolubricantes, no es necesario ningún fluido de trabajo, lo que garantiza una compresión completamente en seco.

Sus dimensiones compactas posibilitan su instalación sencilla prácticamente en cualquier lugar.

Todos los productos SECO SD

SECO SV

- Tecnología de vacío de paletas rotativas de funcionamiento en seco

- Generación de vacío fiable libre de aceite

- Construcción robusta

- Cojinetes lubricados de por vida

- Dimensiones compactas

- Fabricación precisa de primera clase

Ventajas de la serie SECO SV

Las bombas de vacío de paletas rotativas en seco SECO SV son la elección ideal para cualquier aplicación en la que se requiera un vacío fiable y sin aceite. Estas son idóneas para su uso en aplicaciones de pick and place, para los sectores de agarre y sujeción, médico, electrónico, de embalaje e impresión.

Gracias a las paletas de rotor autolubricantes, no es necesario ningún fluido de trabajo, lo que garantiza una operación completamente en seco.

Sus dimensiones compactas posibilitan su instalación sencilla prácticamente en cualquier lugar.