How does vacuum evacuation work?

One of the most widespread applications of vacuum technology is the evacuation of physical spaces, for example vessels. Ambient air or other gases are extracted until a defined target pressure is reached.Vacuum evacuation is a highly diverse application. Evacuation chambers are used in a large variety of processes. To conduct manufacturing or testing processes that would be impeded by the presence of ambient air, or by the presence of oxygen.

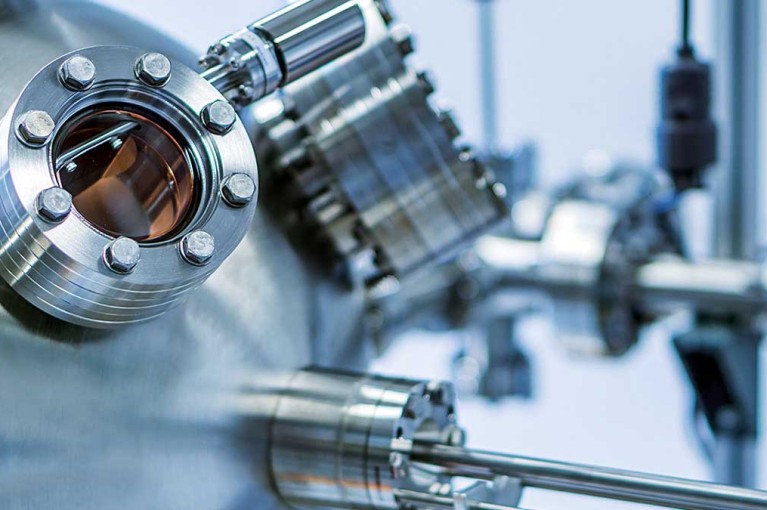

Typical examples where vacuum evacuation is used are process chambers in the semiconductor industry or space simulation chambers. But also the evacuation of vacuum furnaces or coating chambers.